You may have heard the term “Industry 4.0,” but you’re unsure what it is. It is a term used to describe the fourth industrial revolution.

This revolution is driven by advances in digital technology, including the internet of things, artificial intelligence, and 3D printing.

This article will explore what industry 4.0 is, its evaluation, how it differs from previous industrial revolutions, and its impact on the manufacturing industry.

What is Industry 4.0?

It is a term used to describe the fourth industrial revolution. This term was coined by German economist Dr. Klaus Schwab in 2011. It is characterized by several vital technologies coming together to create smart factories.

These technologies include cyber-physical systems, the internet of things, big data, and cloud computing.

It enables companies to automate processes, collect and analyze data and make better real-time decisions. As a result, factories can become more flexible, efficient, and responsive to customer needs.

History

The first industrial revolution

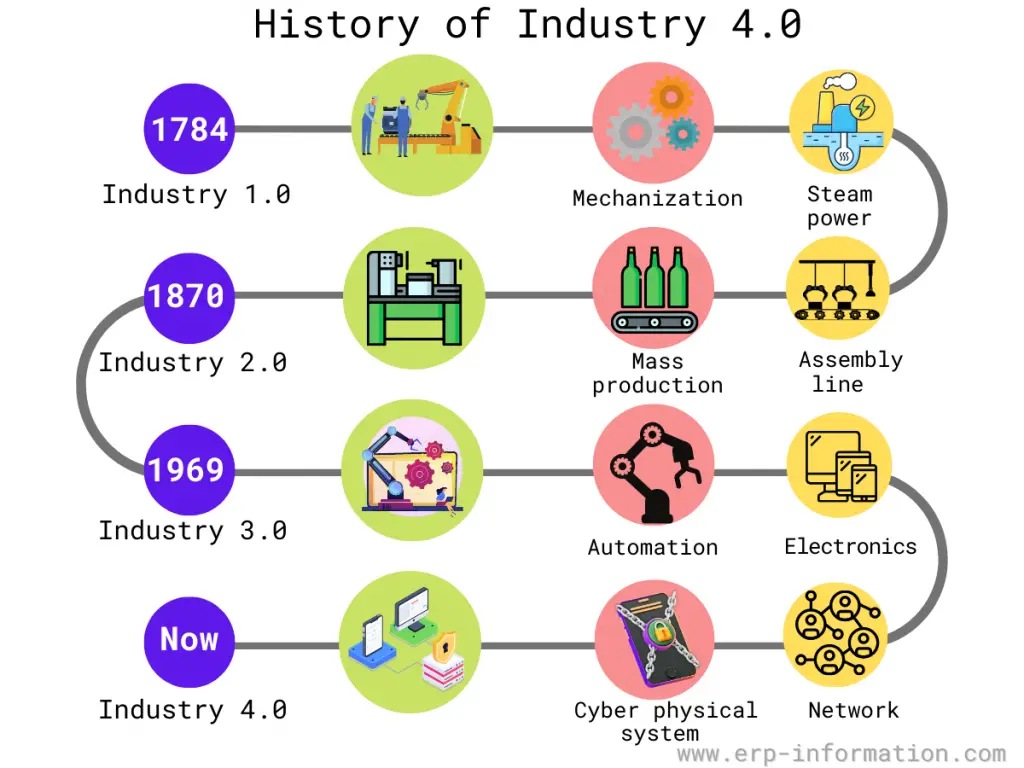

The first industrial revolution began in the late 18th century and was characterized by the introduction of mechanized production techniques. These technologies included water-powered looms, steam-powered engines, and the use of coal to power factories.

The introduction of these technologies led to increased efficiency and productivity in manufacturing and business profits.

The first industrial revolution also significantly impacted society, leading to the rise of new social classes, including the working and middle classes.

In addition, the industrial revolution resulted in a significant increase in population growth and urbanization as people flocked to cities in search of work. The first industrial revolution was a pivotal historical moment that changed the world forever.

The Second Industrial Revolution

The second industrial revolution occurred in the early 20th century and was marked by the widespread use of electric power, mass production, and assembly line. The technologies used in the second industrial revolution were electrification, mass production, and assembly line.

Electrification is the process of using electricity to power machines. It can be done by using electric motors or connecting machines to a central power source.

Mass production is the process of manufacturing products on a large scale. That is usually done using machinery and assembly lines.

Assembly lines are systems where each worker is responsible for completing one task on the product before it moves on to the next worker.

This allows for products to be made very quickly and efficiently. The technologies used in the Second Industrial Revolution were essential in helping factories to produce more goods at a lower cost.

The third industrial revolution

The third industrial revolution was a period of intense change and innovation that occurred in the late 20th century.

It was driven by the introduction of computers and automation, which led to new technologies and production methods. The most notable changes during this period were manufacturing, transportation, and communication.

In manufacturing, computer-controlled machines replaced human workers, increasing productivity and efficiency. In transportation, computerized systems made it possible to track vehicles and ship goods more quickly and efficiently.

And in communication, the internet and email have become essential tools for businesses and individuals worldwide. As a result, the third industrial revolution transformed the world economy and shaped the modern world as we know it today.

The fourth industrial revolution

The fourth industrial revolution is the result of the digital revolution that has been happening since the early 2000s.

Technologies such as big data, artificial intelligence, the internet of things, and 3D printing play a role in this latest industrial revolution.

This transforms manufacturing and many other industries, making them more efficient and productive. It’s also creating new opportunities for businesses and workers alike.

Industry 4.0 technologies can help businesses improve their products and services and become competitive. For workers, these technologies can help them upskill and reskill to keep up with the changing demands of the workforce. Ultimately, the fourth industrial revolution is helping to shape a better future for us all.

Industry 4.0 software helps companies adapt to this digital revolution by connecting their machines and systems to the internet, exchanging data, and automating their processes.

These software solutions can help companies improve efficiency, flexibility, and quality while reducing costs.

How does Industry 4.0 differ from previous Industrial revolutions?

The fourth industrial revolution is different from previous industrial revolutions in several ways.

- It is driven by industry 4.0 technologies like digital technology advances, including the internet of things, artificial intelligence, and 3D printing.

- It is global and affects all industries.

- It is characterized by increased automation, data exchange, and the internet of things in manufacturing.

- It has led to new business models and new players in the manufacturing industry.

Industry 4.0 impact on the manufacturing industry

It has significantly impacted manufacturing, allowing for more efficient and automated product production. That has increased productivity, company cost savings, and improved product quality.

Additionally, It has enabled companies to better meet the needs of their customers by providing them with more personalized products and services.

How can businesses prepare for the fourth industrial revolution?

Businesses can prepare for the 4th industrial revolution by understanding the technologies and trends driving it. They can also invest in digital transformation initiatives to improve their operations and become more competitive.

Additionally, businesses should consider how Industry 4.0 will impact their specific industry and sector and plan to adapt to these changes.

FAQs

What are the benefits of Industry 4.0?

The benefits include increased efficiency and productivity, as well as improved flexibility and customization. Industry 4.0 can also help create new business models and open new markets.

What are some of the challenges associated with Industry 4.0?

Some of the challenges include the need for high-speed, reliable communication networks, the need for data security and privacy, and the need for skilled workers who are familiar with the new technology and processes.

What is the future of Industry 4.0?

The future is difficult to predict, but the fourth industrial revolution will profoundly impact our lives and work. It will likely lead to the creation of new industries and jobs and the demise of others. However, it will also significantly impact how we interact with technology and the role of humans in the future of work.

Conclusion

Industry 4.0 is the fourth industrial revolution which refers to a period of rapid change in manufacturing characterized by the increased use of cyber-physical systems, the Internet of Things, and cloud computing.

These software solutions can help businesses keep up with this rapidly changing landscape by providing real-time data collection and analysis, process optimization, and predictive maintenance.

By investing in industry 4.0 software solutions, businesses can stay ahead of the curve and remain competitive in the global market.