Explore the fascinating journey of Enterprise Resource Planning (ERP) from its early days to the cutting-edge technologies of today. This journey traces the incredible evolution of how businesses handle their resources.

Join us on this adventure through history, discovering how ERP has transformed from its beginnings into the powerhouse it is today, setting the stage for tomorrow’s integrated business solutions.

This post explains the complete history of ERP software system, the ERP evaluation path, and its future. It also discusses the difference between ERP and MRP.

Even though understanding ERP is a little confusing, it is good to understand it for all businesses, especially manufacturing.

ERP software systems in manufacturing industries have proven effective and efficient.

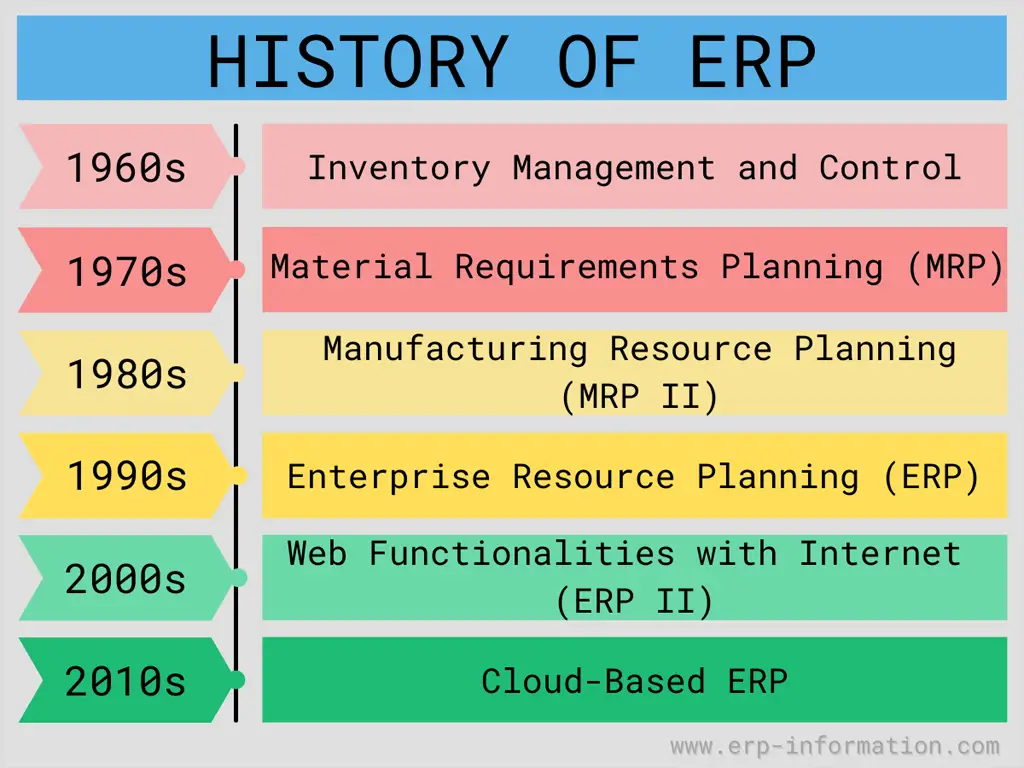

The history of ERP dates back to 1960!

ERP (Enterprise Resource Planning) is the evolution of Manufacturing Resource Planning (MRP II).

Evolution of ERP

Enterprise resource planning (ERP) is a tool that has been improved over the last six decades. People have made changes to how businesses are managed, and technology has gotten better. This helped ERP become more strategic.

Two Aspects of the History of ERP

From a business perspective, ERP has expanded from coordinating manufacturing processes. In addition, it grew to integrate enterprise-wide backend processes.

ERP has evolved from legacy implementation to a more flexible tiered client-server architecture from a technological aspect.

Inventory Management & Control – The 1960s

ERP history begins with inventory management and control. In the 1960s, manufacturing industries found that they required a system that should manage, monitor, and control their inventory.

Inventory Management and control combine information technology and business processes to maintain the appropriate stock level in a warehouse.

The activities of inventory management include,

- Identifying inventory requirements

- Setting targets

- Providing replenishment techniques and options

- Monitoring item usages

- Reconciling the inventory balances

- Reporting inventory status

Material Requirements Planning (MRP I) – The 1970s

The next stage of the history of ERP is material requirements planning.

In the 1970s, material requirements planning evolved to meet the manufacturing industries’ needs.

Material requirements planning (MRP I) utilizes software applications for scheduling production processes. It generates schedules for operations and raw material purchases.

Scheduling is based on,

- Production requirements for finished goods

- Structure of the production system

- Current inventory levels

- Lot-sizing procedure for each operation

Manufacturing Resource Planning (MRP II) – The 1980s

The last stage of the ERP evolution is manufacturing resource planning.

In the 1980s, vendors added more manufacturing processes to MRP to make the process easier and more accurate. This new system is called manufacturing resource planning (MRP II).

Manufacturing Resource Planning or MRP II utilizes software applications and applications for coordinating manufacturing processes. Processes from product planning, parts purchasing, and inventory control to product distribution.

Enterprise Resource Planning (ERP) – The 1990s

For the first time in the 1990s, The Gartner Group used the term ERP.

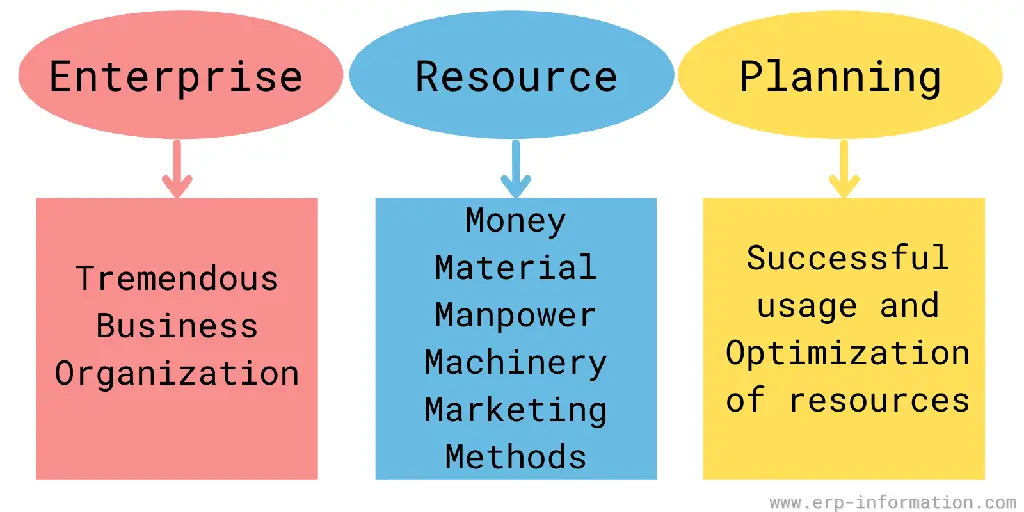

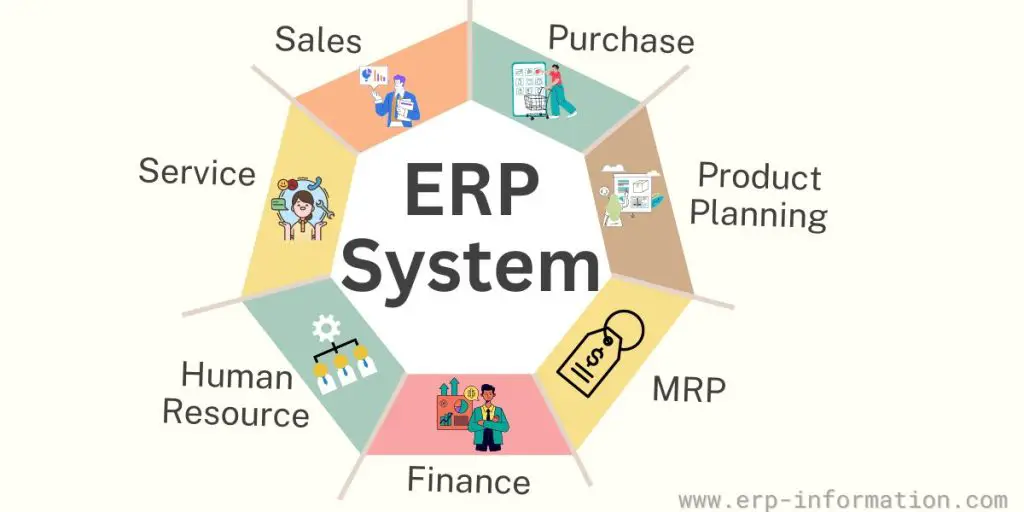

Enterprise Resource Planning, or ERP, uses a multi-module application software system. Software for improving the performance of the internal business processes.

ERP systems often integrate business activities across functional departments.

Departments including,

- Product planning

- Parts purchasing

- Inventory control

- Product distribution, fulfillment, and order tracking

ERP software systems may include application modules to support,

- Marketing

- Finance

- Accounting

- Human resources

During this period in the history of ERP, big corporations implemented it. However, most small and medium-scale businesses are left out due to the higher upfront costs.

Web Functionalities with Internet (ERP II) – The 2000s

Interaction of ERP with other application suites is enabled in ERP II. An example is integrating with CRM (Customer Relationship Management) systems.

Technological advancement in accessing information using internet web browsers and mobile devices was made possible.

ERP II adapted technological advancement with Service Oriented Architecture (SOA).

Cloud-based ERP – The 2010s

Business applications are delivered as a Software as a Service (SaaS) model. Servers are deployed on the cloud and accessed with the rest APIs. Android, iOS, and browser applications are developed for delivering ERP software in the SaaS model.

It is helping businesses of all scales start using ERP systems since the upfront cost of cloud ERP systems is relatively minor.

Most of the prominent top ERP vendors are delivering services over the cloud.

Evolution of Open Source ERP Solutions

Along with commercial vendors, open-source ERP systems have also evolved. These systems are mainly catering to the requirements of small and medium-scale businesses.

Since there is less upfront cost involved while implementing these systems, businesses with less budget could also afford it.

There is a surge in service providers who help implement and customize open-source ERP solutions.

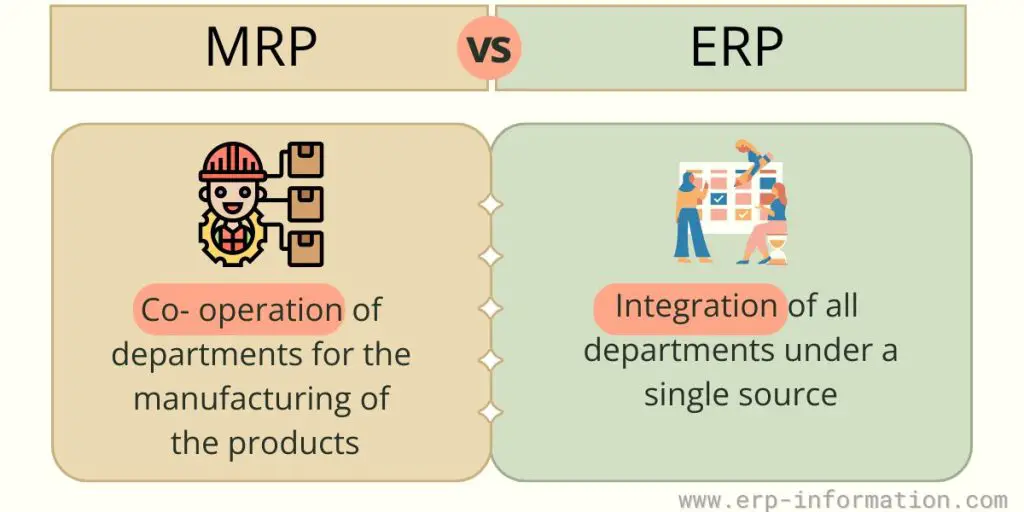

Difference Between MRP and ERP

Here are some differences between MRP and ERP.

| MRP | ERP |

| It means material requirements planning. | It means enterprise resource planning. |

| It is a solo software. | It can integrate with other systems or software easily. |

| You can integrate it with other software, but that is challenging. | It combines with other software or modules without any difficulty. |

| It suits manufacturing industries. | It suits all industries and huge enterprises because it can fulfill the requirements of large industry departments with its modules. |

| Types of its users are minimal because only the manufacturing department uses it. | Types of its users are maximum with extended users in different departments. |

| It is less expensive. | It is more expensive. |

Open Source ERP vs Cloud ERP

| Open Source ERP | Cloud ERP |

| You can customize the code, rewrite the code, and generate a new code version. | You can not edit the code. |

| It suites industries with less required functionalities | It suits big sectors that need a wide variety of features. |

| It is entirely free. You need to pay only for services. | Upfront costs and subscription charges are included. |

Check our ERP Implementation Cost Calculator to calculate implementation costs.

Future of ERP Systems

Compared with the history of ERP, its future ERP trends are more dynamic due to the advancement in technology.

- Due to the reduction of computation and data storage costs, collecting every minute detail of business events is possible. In addition, it opens up the possibility of extensive data analysis and advanced reporting.

- Machine learning can help suggest better business decisions based on previous data and industry benchmarks.

- Automation of data-driven decision-making will take the front seat with the help of artificial intelligence.

- Business transactions between multiple parties are establishing data integrity with blockchain technology.

- Virtual reality is for better interactions to avoid friction due to physical proximity.

- Mobile ERP app allows users to work with their device anytime anywhere that boosts productivity.

- Internet of Things (IoT) for better data exchange between human-to-machine and machine-to-machine.

The advancement in technology has always accompanied the history of ERP. It continues to boost business growth.

With SaaS-based cloud ERP systems, more and more companies can start using enterprise resource planning solutions in their business operations.

FAQs

What is the significant difference between open-source ERP and commercial ERP?

The significant difference between open-source ERP and commercial ERP is source code. In an open-source ERP system, source code is publicly accessible. But you must pay for the source code license in a cloud system.

What is ERP II?

ERP II, coined by Gartner in 2000, marks the evolution of ERP systems into internet-enabled solutions. It is often referred to as “Extended ERP” or “Next-Generation ERP,” encompasses cloud-based platforms and utilizes web connectivity to facilitate seamless information exchange among diverse applications.

What is the difference between ERP and ERP II?

ERP focuses on internal operations and managing resources within the organization’s boundaries. It streamlines processes like finance, HR, and inventory management.

On the other hand, ERP II expands beyond these boundaries, venturing into collaboration with external partners, customers, and suppliers. It integrates more advanced functionalities like CRM, BI, and SCM to enable real-time information sharing and enhance decision-making across the interconnected network of stakeholders.

What is mobile ERP?

Mobile ERP refers to enterprise resource planning (ERP) software that is specifically designed and optimized for use on mobile devices such as smartphones and tablets.

ERP users can access and interact with ERP modules, functionalities, and data while on the go, outside of traditional office environments.

Conclusion

The evolution of ERP has been a remarkable journey. It is marked by continuous innovation and adaptation to changing business requirements.

From its origins in inventory management to the sophisticated, interconnected systems of today, ERP has revolutionized how organizations operate and compete in the global marketplace.

Looking ahead, the future of ERP systems holds even more promise, with advancements such as mobile ERP, machine learning, artificial intelligence, blockchain, and IoT poised to further transform business operations and drive growth.