Businesses must keep track of their stock levels to avoid running out of products and losing sales. However, this cannot be easy to do manually.

It’s hard enough to keep track of your stock levels, but it’s even harder when you have to do it manually. In addition, this process can take up a lot of time and energy that could be better spent on other tasks.

Target Inventory Level is the solution to your stock level tracking woes. This formula considers five primary zones – ideal, caution, danger, critical, and lost – to help you make more informed decisions about your stock.

This post discloses the concept of target inventory level. It tells about the target inventory level, formula, benefits, zones of stock level in inventory, and the difference between safety stock and target inventory level.

Assess your target inventory with our Target Inventory Level Calculator

What is the Target Inventory level?

Target inventory levels are the amount of inventory a company will maintain in terms of days’ supply. This level should be low enough to avoid stockouts and high enough to ensure that production capacity can meet demand during peak periods.

The Target Inventory Level is the optimal amount of supplies for a company at any time. It’s essential not only for preventing shortages but also for ensuring sufficient materials are available when needed, most during periods of increased customer demand or other emergencies.

In a min-max inventory system, it is the equivalent of the maximum. Thus, the target inventory equals the order point plus a variable order quantity.

In summary, target inventory is the maximum stock quantity the company holds at any time.

Advantages of Target Inventory

- It helps to reduce the risk of running out of stock.

- It reduces the risk of loss of revenue.

- It increases the gross profit.

- It increases the efficiency of production.

- It helps to develop a good relationship with customers.

Target Inventory Level Formula

TI = d(RP+L)+SS

Here, d= Average period demand

RP= Review period(days,weeks)

L= Lead time (days, weeks)

SS= Safety Stock

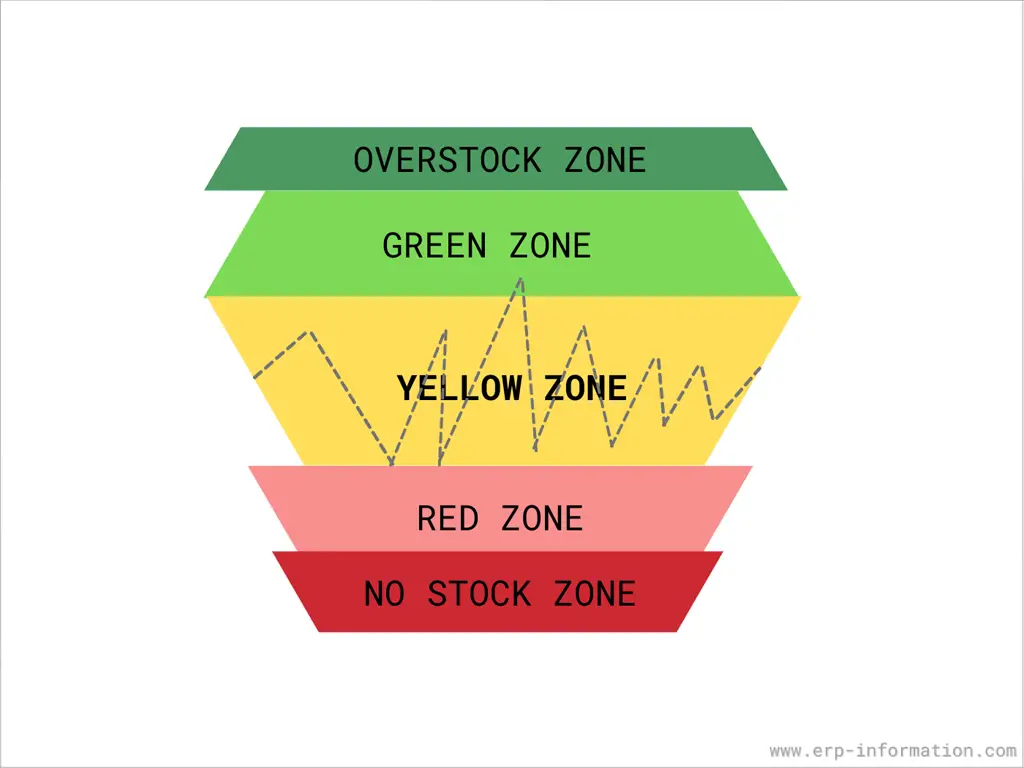

Five Major Zones of the Stock Level of Inventory

1. No Stock Zone

At this level, the stock is zero, which is below the minimum stock level. This zone alerts the organization, and the organization’s management should take action immediately.

The most important thing is the organization should avoid this situation by getting the required materials in less time.

2. Red Zone

This zone represents the minimum stock level of inventory. The organization should maintain this minimum quantity for safety. Therefore, this zone is also called a safety level.

3. Yellow Zone

This zone refers to the average stock level. That means it is a level that is above the minimum stock level and below the maximum stock level.

Most of the organizations held the average inventory quantity for a given period.

4. Green Zone

This zone refers to the maximum stock level of inventory. This is the ultimate limit of stock that an organization can hold. If the stock quantity exceeds this level, that is called too much stock or overstock.

5. Over Stock Zone

This zone represents too much stock of inventory. Overstocking leads to an unfavorable effect on the organization.

Optimum inventory levels

These are the absolute quantities of items that a company should have in a fulfillment center at any given period.

Safety Stock

Let us define safety stock.

Safety stock is an extra amount of an item held by the company to avoid the risk of an unexpected increase in demand. It helps to prevent stockouts. The root cause of stockouts is a sudden increase in demand, improper stock forecast, and up&downs in the lead time of raw materials.

The formula for safety stock is

Safety stock = (ISL X supply variability) + (ISL X demand variability)

where ISL means initial stock level.

This standard formula is unsuitable for all industries as the factors that impact the supply chain differ from industry to industry.

Hence while calculating safety stock, industries need to consider those factors along with the standard formula.

Safety Stock Formula

Following are the different formulas for calculating safety stock. You can choose suitable formulas for your industry by knowing all these formulas.

- Basic formula: It is the most common formula for safety stock calculation.

- Average-max formula: It is a general formula. But if you have an extended lead time, it is unsuitable for your industry. The formula is SS= (maximum sale X maximum lead time) – (average sale X average lead time)

- Normal distribution with demand uncertainty: To find the standard deviation in demand, first calculate average demand and then average variability in demand by taking the square of each month’s difference. Take the average of those squares together. SS = standard deviation of the demand X the root of average delay

- Normal distribution with lead time uncertainty: Formula is SS = Z X average sale X lead time deviation. Where Z is the desired service level

- Normal distribution with on-demand uncertainty and independent lead time: This formula is effective if your demand and lead time are uncertain. SS= Z X square root of (square of average LT multiplied by demand standard deviation) + (square of average sales multiplied by lead time standard deviation)

- Normal distribution with on-demand uncertainty and dependent lead time: Formula is SS = Z X demand standard deviation X square root of average lead time + Z X average sales X lead time standard deviation.

Here we are providing online calculators for all the above formulas

Online Safety Stock Calculator With Ave-Max Formula

Online Safety Stock Calculator With Lead Time Uncertainty

Online Safety Stock Calculator With Demand Uncertainty

Online Safety Stock Calculator With Demand and Lead Time Uncertainty

Check the table for a quick view

| Types of formula | Formula for safety stock |

| Basic formula | (ISL X supply variability) + (ISL X demand variability) |

| Average-max formula | (Maximum sale X Maximum lead time) – (Average sale X Average lead time) |

| Normal distribution with demand uncertainty | (Standard deviation of the demand X The root of average delay) |

| Normal distribution with lead time uncertainty | (Z X Average sale X Lead time deviation) Where Z is the desired service level |

| Normal distribution with on-demand uncertainty and independent lead time | {Z X [Square root of (square of average LT multiplied by demand standard deviation) + (square of average sales multiplied by lead time standard deviation)]} |

| Normal distribution with on-demand uncertainty and dependent lead time | (Z X demand standard deviation X square root of average lead time + Z X average sales X lead time standard deviation) |

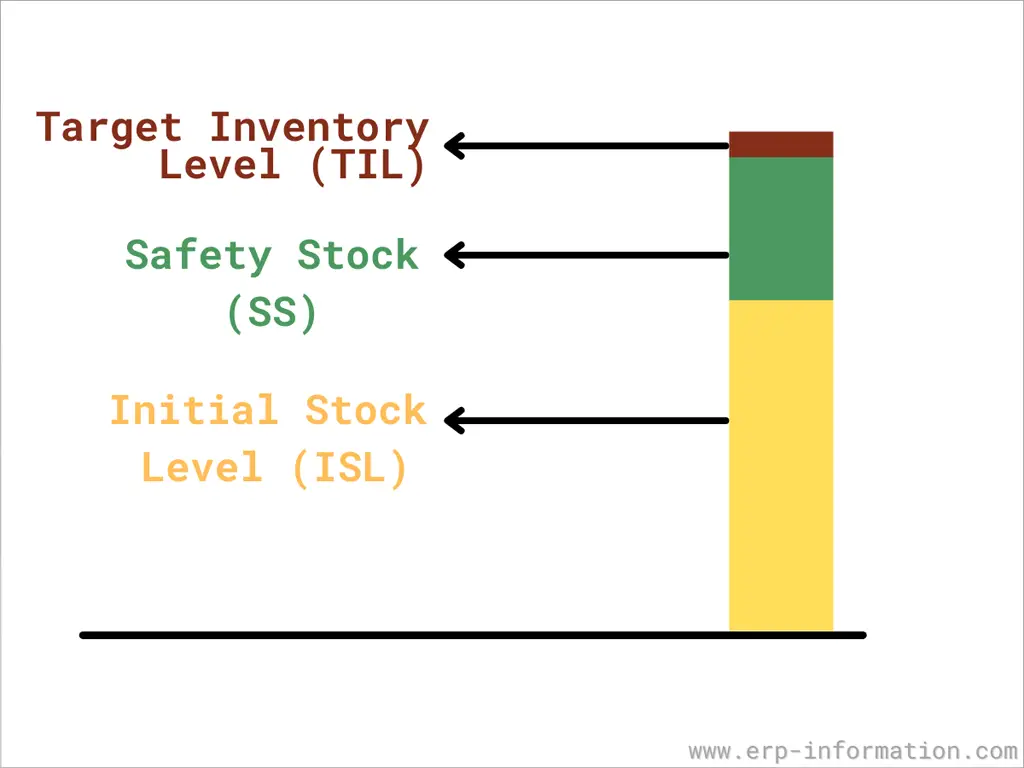

Target Inventory Level vs Safety Stock

Safety stock is different from target inventory. Safety stock is an extra quantity of an item the company keeps to avoid being out of stock of that item.

Target inventory is the quantity of a company item at a given moment. Safety stock is a sub-component of the target inventory level. At the same time, we consider safety stock by calculating the target inventory level.

| Target Inventory Level | Safety Stock |

| It represents the desired quantity of inventory to meet the regular anticipated demand. It is a more strategic approach aligned with expected demand and production capabilities. | Safety stock is buffer stock against unexpected fluctuations in demand or supply chain disruptions. |

| It’s the ideal amount of inventory that a company aims to maintain based on forecasted demand, production capabilities, and customer service levels. | It is an extra quantity of inventory maintained beyond the expected demand during lead time. |

| It helps in efficient production scheduling, order fulfillment, and balancing between customer satisfaction and inventory costs. | It helps to mitigate the risk of stockouts, ensuring that even during unexpected spikes in demand or delays in replenishment, there’s sufficient inventory to fulfill orders. |

Target inventory level (TIL) is also calculated using an initial stock level and safety stock. That is

Target inventory level (TIL)= Initial Stock Level (ISL) + Safety Stock (SS)

Safety Stock vs Cycle Stock

| Cycle stock | Safety stock |

| It is the inventory normally kept on hand to meet regular demand or maintain the production of goods. | It is additional inventory kept on hand as a precaution against unexpected demand or supply chain disruptions. |

| It is the inventory that is regularly purchased and consumed over a specific period, such as during a production cycle or a sales period. | The inventory is held in excess of what is normally required to meet regular demand. |

| It is a predictable and recurring expense. | The inventory is held in excess of what is normally required to meet regular demand. |

Evaluate Cycle Service Level using our Cycle Service Level Calculator Online

FAQs

What are inventory levels?

There are many factors to consider when determining inventory levels for your business. The first is your forecasted demand.

This will give you an idea of how much inventory you will need on hand to meet customer needs. You will also need to consider your lead time or the time it takes to receive new merchandise from your supplier.

If you have a long lead time, you must maintain higher inventory levels to avoid running out of stock.

How do you calculate the target inventory level?

A target inventory level is calculated by adding the initial stock level (ISL) and safety stock (SS) levels, giving the required average monthly demand rate.

Safety stocks are needed for any company to comfortably manage its supply chain uncertainty, including shortages or unexpected jumps in customer demand.

Safety stocks have another characteristic: they are held in higher locations to be delivered quickly when customers need them without spoiling.

The difference between an emergency stock and a safety stock is that emergency stocks are eventually distributed, even if not immediately. Ultimately, you don’t want any product sitting around shelves waiting for customers.

What is cycle stock?

Cycle stock refers to the regularly purchased and consumed inventory over a specific period.

For example, the manufacturer keeps inventory in stock to meet continuous demand or to maintain the production of goods.

In other words, cycle stock is the inventory used to fulfill regular customer orders and is typically replenished regularly.

Conclusion

Summing up our exploration of target inventory levels, we’ve defined what they are and dived into the five key zones that help manage them. We’ve even uncovered the math behind calculating these levels.

This article explained to you how target inventory levels can bring several advantages, including keeping operations smooth and customers happy. Plus, demystified safety stock and its significance, understanding its formula and purpose.

Lastly, we’ve clarified the difference between target inventory levels and safety stock, knowing when to use each one.