Maintaining precision and accuracy are important requirements of inventory management. One of the key methodologies that contribute significantly to this endeavor is cycle counting.

It is a systematic approach to auditing and validating inventory levels within an organization.

It differs from traditional physical inventory counting, where the entire stock is counted at once, often leading to operational disruptions and inaccuracies.

Cycle counting, on the other hand, focuses on counting a subset of items within the inventory on a recurring basis.

This post will explain cycle counting, how it works, its importance, disadvantages, best practices, methods, and some benefits of using it to manage your inventory.

After reading this post, we hope you’ll better understand inventory counting and how it can help you keep track of your inventory more effectively.

What is Cycle Counting?

It is a method of counting inventory items regularly. These frequent counts aim to identify and correct discrepancies between the physical count and the inventory records. That helps to ensure that the inventory records are accurate and up-to-date.

What is Inventory Cycle Count?

Inventory cycle counting is a periodic inventory process where specific items in the inventory are counted to ensure their accuracy. The counting can be done manually or through automated processes.

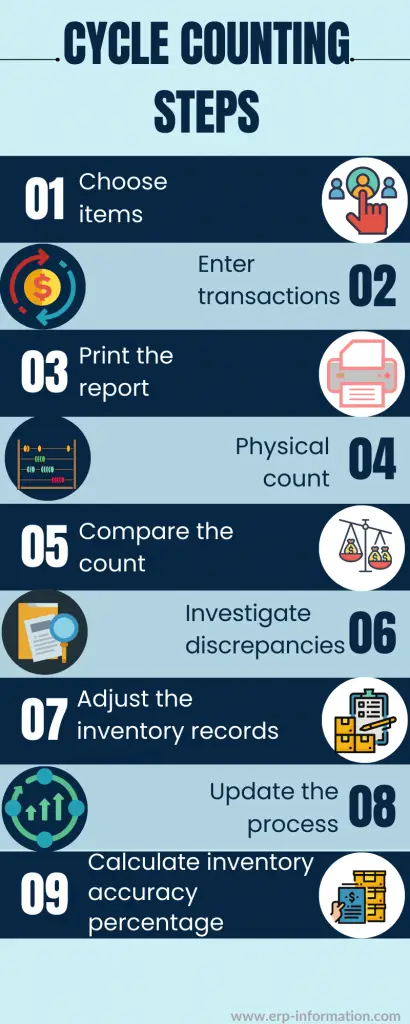

Cycle Counting Procedure

The following steps or procedures are useful to perform inventory cycle counts.

1. Choose the items to be counted

The first step in it is choosing the items you will count. You can do this by selecting specific items or product categories.

2. Enter all transactions of the inventory item

Make sure all transactions are updated in the inventory database. Daily cycle counts need to be added to transactions.

3. Take out the print of the counting report

The counting report contains the item’s bin location, assignee, and the number of items in the inventory database.

4. Physical count

The next step is to count the items physically. Physical inventory count can be done by using a manual process or an automated process. The manual count may have human error.

5. Compare the count to the reports

After that, compare the count to the records. That will help to identify any discrepancies between the two.

6. Investigate any discrepancies

Investigate any discrepancies that are found. You can do this by looking at the records and investigating the cause of the difference.

7. Adjust the inventory records

After the investigation is complete, the inventory record database should be updated to eliminate inventory errors after the cycle count.

8. Update the cycle counting process if needed

If needed, enhance the procedure, train the employees, and do the needful thing to eliminate the error during cycle count.

9. Calculate the inventory accuracy percentage

Regularly audit the inventory and do calculations for an inventory accuracy percentage.

Importance of Cycle Counting in Inventory Management

1. Real-time Accuracy

One of the primary advantages of this approach lies in its ability to maintain real-time accuracy in inventory levels.

By continuously verifying smaller portions of the inventory, discrepancies are identified promptly. This ensures that the recorded inventory levels are a true reflection of what is physically on hand.

2. Minimized Disruption

Cycle counting is an ongoing process that minimizes operational disruptions. Unlike traditional annual or quarterly physical counts that can disrupt normal operations.

It allows organizations to maintain business as usual while ensuring inventory accuracy.

3. Timely Error Identification

Cycle counting provides a timely mechanism for identifying errors in inventory records, such as discrepancies between what the system indicates and what is actually in stock.

This allows organizations to investigate and rectify issues promptly, reducing the chances of costly stockouts or overstock situations.

4. Enhanced Decision-making

Accurate inventory data resulting from cycle counting serves as a foundation for informed decision-making.

It enables organizations to optimize reorder points, reduce carrying costs, and make data-driven decisions regarding stock levels.

5. Improved Customer Service

Reliable inventory counts are vital for fulfilling customer orders efficiently. Cycle counting ensures that organizations have the right products available, leading to improved on-time deliveries and customer satisfaction.

6. Fraud and Theft Detection

Cycle counting can also serve as a deterrent to inventory fraud and theft. When employees are aware that inventory levels are continuously monitored, the risk of unauthorized stock manipulation diminishes.

7. Process Improvement

Continuous cycle counting encourages process improvement. Organizations can identify patterns in discrepancies and address underlying issues in their inventory management processes.

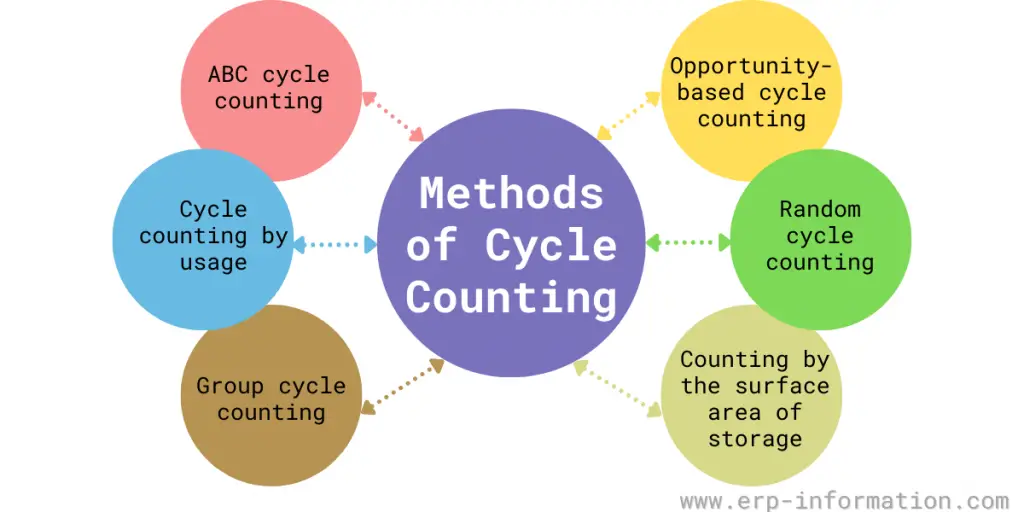

Cycle Counting Methods

ABC cycle counting

In the ABC method, we classify items according to their value. “A” items are the most important and valuable, while “C” items are the least important. The number of inventory counts for each item is based on its value.

Counting by usage

This method classifies items according to how frequently they are used. The most commonly used items are counted more often than those used less often.

Group method

This method counts a group of SKUs (stock-keeping units). The items are grouped based on physical location, count frequency, or other factors.

Opportunity-based method

This method is also known as “floating inventory.” It involves counting items that are not in their usual location.

Random method

In this method, items are selected for counting at random. It is the most common method of counting.

Counting by the surface area of the storage

In this method, items are counted based on the surface area of their storage location. The counting takes place for items in their physical location.

Real-life Examples

Example 1: Retail Store Inventory Management

A retail store, with thousands of different products on its shelves, needs to maintain accurate inventory records while minimizing disruptions to daily operations.

Implementation: The store implements a cycle counting program using the ABC analysis method.

The store then categorizes its products into ‘A,’ ‘B,’ and ‘C’ groups based on sales velocity and value. ‘A’ items include high-value and fast-selling products, ‘B’ items are moderately important, and ‘C’ items are low-value or slow-moving.

Now cycle counting frequencies are assigned according to the categories. ‘A’ items are counted weekly, ‘B’ items are counted monthly, and ‘C’ items are counted quarterly.

Each week, a team of employees focuses on counting ‘A’ items. This is done during non-peak hours to minimize disruptions. The cycle repeats with ‘B’ and ‘C’ items in subsequent weeks.

Result: By implementing cycle counting, the retail store maintains accurate inventory records without the need for full physical inventories, which can be time-consuming and disruptive.

High-value and high-demand products are regularly audited, reducing the risk of stockouts and overstocking while optimizing operational efficiency.

Example 2: Manufacturing Facility Inventory Management

A manufacturing facility relies on a vast inventory of raw materials, components, and finished products. It needs to ensure inventory accuracy to prevent production delays and bottlenecks.

Implementation: The facility adopts a cycle counting program using a location-based method. Firstly the storage areas within the facility are divided into zones based on physical proximity and material type. Each zone is assigned a unique identifier.

Cycle counting frequencies are assigned to each zone based on the criticality of its contents. High-usage zones are counted more frequently. Throughout the year, designated employees conduct cycle counts in their assigned zones.

This involves using barcode scanners and an inventory management system to record counts and identify discrepancies.

Result: The manufacturing facility benefits from real-time inventory accuracy without interrupting production. By focusing on specific zones, cycle counting ensures that high-impact areas are audited regularly, minimizing the risk of production delays due to inventory discrepancies.

Cycle Counting Best Practices

- End up all the transactions for the inventory items before counting

- Select items that are high value or have a high turnover rate for cycle count

- Choose the inventory of the same category at a time

- Assign the responsibility of counting to a particular employee

- Use the right tools for the job.

- Train employees effectively.

- Label the inventory items with count numbers

- Use wireless barcode scanners for more accuracy

- Make sure counting done for all inventories at least once in a quarter

- Compare the counted quantities with the system-generated reports

- Do not forget to update the records in the system after counting.

- Investigate the process when the error comes

- Record process, changes, and results

By following best practices, businesses can ensure that their cycle counts are accurate and helpful in managing inventory.

Advantages of Cycle Counting

- It ensures the accuracy of the inventory.

- It helps to detect any discrepancies in the inventory

- It keeps the inventory up-to-date

- Improves the efficiency of the inventory management system process

- Reduces the cost of inventory management

- It helps to improve customer satisfaction

- Reduces the risk of stock-outs

- Decision-making in inventory management

- It helps to increase the turnover of the inventory

- Improve the overall efficiency of the business

Disadvantages of Cycle Counting

- It can be time-consuming and labor-intensive.

- Counting all the items in the inventory takes a lot of time and work. It can be very tiring.

- It can also be expensive to implement an automated inventory counting process.

- If the same inventory item is stored in different locations, there will be confusion about record updation after the count.

Cycle Counting vs Physical Counting

| Cycle Counting | Physical Counting |

| Done regularly (daily, weekly, monthly, or quarterly) | Done annually or occasionally |

| Done on a selected number of items | Done on all items |

| Done using a barcode scanner or a counting machine | Done manually |

| It is less time-consuming and less labor-intensive | Comparatively high time-consuming and labor incentive |

| It is more accurate inventory counts | Comparatively less accurate |

| The disruption level is low | Disruption is high |

FAQs

What is the purpose of cycle counting?

The purpose of it is to ensure that the inventory is accurate and up-to-date by counting inventory regularly. That helps to prevent over or understocking.

What is a good cycle counting accuracy?

A good cycle counting accuracy is 95% or higher. That means the inventory is accurate within 95% of the actual quantity of items in stock.

What is The Frequency of Cycle Counting Methods?

It refers to how often a business conducts inventory counts to ensure the accuracy of its stock levels. This frequency varies depending on the chosen cycle counting approach and the company’s specific goals and needs.

Different methods, such as ABC analysis, usage-based counting, or random sampling, may involve counting items at different intervals, ranging from daily to annually.

The choice of frequency aims to strike a balance between maintaining

precise inventory records, managing costs, optimizing operational efficiency, and mitigating risks associated with inventory discrepancies.

Choosing the right frequency for cycle counting is unique to your business and should be regularly evaluated and adjusted as your inventory and business needs change. The goal is to maintain accurate inventory records while optimizing operational efficiency and cost-effectiveness.

How do you determine the optimal frequency for cycle counting in the organization?

The frequency of cycle counting depends on factors like item value, demand, and risk tolerance. Conduct a thorough analysis of your inventory to classify items and prioritize counting based on these factors. Regularly review and adjust your frequency to align with changing business needs.

Can cycle counting completely replace annual or periodic physical inventories?

While cycle counting offers ongoing verification, it may not eliminate the need for occasional full physical inventories, especially for financial reporting or auditing purposes. The choice depends on your specific industry, regulations, and internal policies.

Can technology and software solutions enhance the efficiency of cycle counting processes?

Yes, technology plays a significant role in automating cycle counting. Utilize inventory management software, barcode scanners, RFID technology, and data analytics to streamline the process, reduce human error, and gain real-time visibility into inventory accuracy.

Conclusion

Cycle counting is a vital process in inventory management. Regularly counting your inventory can catch discrepancies and prevent them from becoming more significant problems. In this way, it can save your time and money in the long run.

Following best practices and using the proper techniques will help you get the most out of your cycle count. We hope you found this post helpful.