A Reorder Point system is an inventory control that helps businesses maintain an appropriate inventory level and avoid shortages.

This system works by requiring managers to order more products when the current supply of products falls below a predetermined amount.

The ROP system can be applied to almost any product, but it is most commonly used in discrete manufacturing, where many components or raw materials are involved.

This post will discuss how an ROP system functions, its formula, its calculation, its strategies, and its advantages.

Find your reorder point using our free, online Re-order Point Calculator

You can also calculate fixed order quantity using our Fixed Order Quantity Calculator

Key insights

- The reorder point is essential to maintain an optimal balance between inventory levels and customer demand.

- The formula for calculating it is essential for determining the ideal inventory level.

- Some strategies help mitigate the risks of both overstocking and understocking by aligning inventory with demand dynamics and supply chain efficiency.

Definition

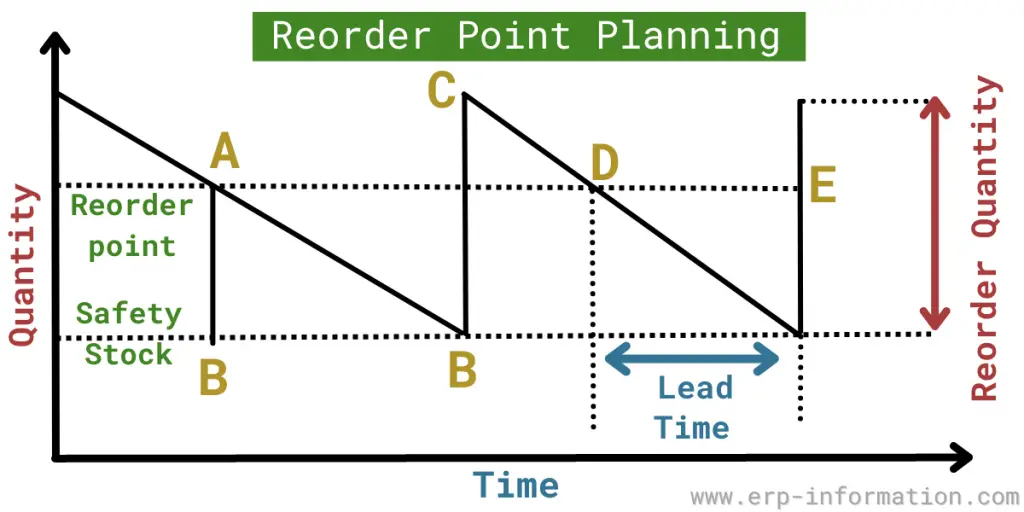

Reorder Point is a popular inventory control method. This system monitors your inventory levels and orders more when the level drops below a certain point.

Some companies also include safety stock in their calculations to ensure they never run out of product. There are many benefits to using this system, including increased efficiency and reduced costs for over-ordering or under-ordering products.

That will help ensure no interruption in production and save on extra costs.

The reorder point differs because of every item’s importance and usage rate in the production process.

It also depends on several other factors, such as discounts, the item’s delivery time, safety stock, and so on.

With the evolution of ERP, this process is automated and straightforward. All the crucial is tracked in the system and is taken care of.

Early ordering also helps cut down high costs put forth by vendors and administers good negotiation.

Importance

Cost-Effective Inventory Management

| Striking a balance between reordering too much, too soon, and waiting too long optimizes costs. Ordering excessively can lead to unnecessary expenditures and carrying costs for excess inventory. Meanwhile, delayed reordering or ordering only when stock is depleted results in potential stockouts, impacting customer satisfaction and sales. A well-defined reorder point minimizes these risks by aligning replenishment with actual demand, optimizing cash flow, and reducing carrying costs. |

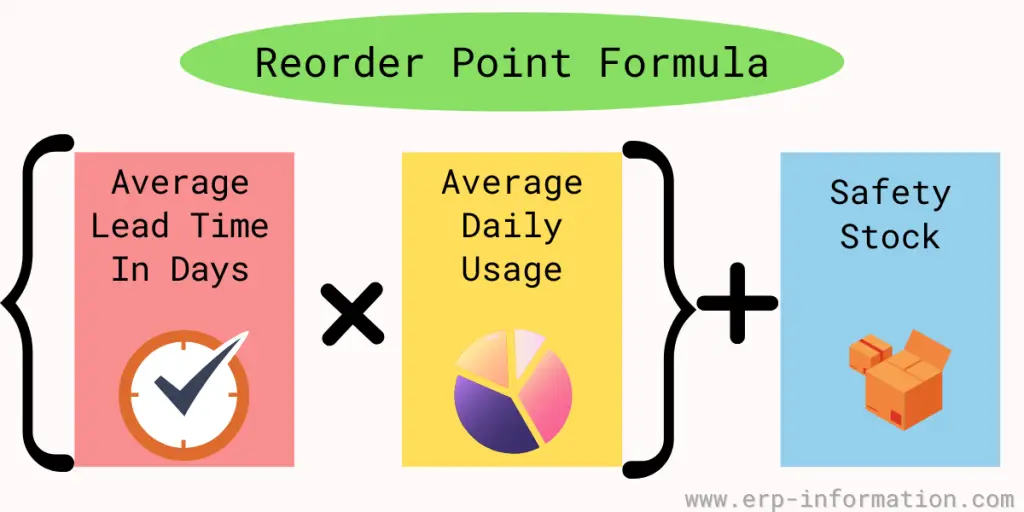

Reorder point formula with safety stock

Reorder point = (Average lead time in days X Average daily usage )+ Safety Stock

Lead time is the difference between a purchase order issued and product delivery. Safety stock is the number of materials or products stocked in the warehouse during unexpected emergencies.

Calculation of reorder point

To calculate the reorder point, you must calculate lead time in days and safety stock. ROP can be calculated without safety stock also. Will provide both calculations below.

Example

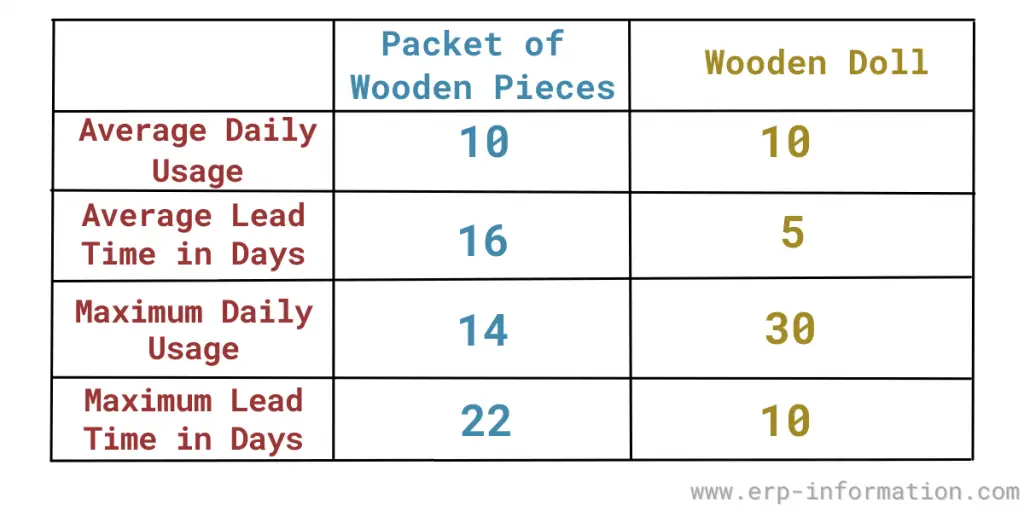

For example, let us assume a company sells wooden dolls. For that, it needs wooden pieces. To produce one doll, the company requires one pack of wooden pieces.

The company requires ten wooden pieces per day to produce ten dolls. But when the company does maximum production, it requires 14 packets per day.

Once the company places the purchase order, it takes 16 days to deliver the wooden pieces. However, sometimes delays happen in supply. Hence lead time extends up to 22 days.

The company takes, on average, five days to produce one doll, but occasionally it takes ten days to make one doll because of the delay in the production process.

That makes company sales, on average, ten dolls per day. Sometimes, it will be 30 dolls per day, depending on the demand.

Now, we put all data in the form of a table.

Calculating ROP with safety stock

First, we calculate safety stock for packets of wooden pieces. Formula is

Safety Stock = (Maximum Lead Time in Days X Maximum Daily Usage) – (Average Lead Time in Days X Average Daily Usage)

Safety stock of Packets = (22 X 14)-(16 X 10)

= 148

Safety stock of Dolls = (10 X 30)-(5 X 10)

= 250

ROP of packets = (Average lead Time in days X Average daily usage )+ Safety Stock

= (16 X 10)+148

= 308

ROP of dolls = (Average lead Time in days X Average daily usage )+ Safety Stock

= (5 X 10)+250

= 300

Calculating ROP without safety stock

ROP of packets = (Average lead Time in days X Average daily usage )

= (16 X 10)

= 160

ROP of dolls = (Average lead Time in days X Average daily usage )

= (5 X 10)

= 50

Reorder point calculation with different vendors

Assume that you are a retail shopper and sell soft drinks and snacks. You purchase them from different vendors with different lead times.

Let us see the calculation.

The soft drinks are delivered in 2 days, but the snacks are delivered in 3 days. You sell 5 soft drinks bottles and 6 snack boxes in a day.

Here we calculate the ROP without considering safety stock.

Your ROP with the soft drinks vendor will be

ROP = Average lead time x Average daily usage

= 2 X 5 = 10 bottles.

You must raise the order for soft drinks bottles when 10 bottles are left with you.

Your ROP with the snack boxes vendor will be

ROP = 3 X 6 = 18 boxes.

You must raise the order for snack boxes when you have 18 boxes with you.

Advantages of reorder point

Getting accuracy in finding the reorder point in inventory control has the following advantages.

- One of the key benefits of this system is that it allows a smooth inventory flow with no halts in between. This further builds on the inventory discipline of your business.

- It makes space to identify procurement issues and helps resolve them, leading to a smoother process.

- Makes sure that the stock is available and thus avoids any production glitches.

- Unnecessary expenditure in stocking and maintaining the inventory is reduced.

- It helps the business to make appropriate decisions by helping to track the entire procurement procedure.

Strategies

Calculate your ROP

This can be done using the formula: ROP = (Average lead time x Average daily usage) + Safety stock. Also, use sales forecast knowledge to improve the values.

Set up a system to track your inventory levels

You can consistently monitor your inventory levels by employing either a basic spreadsheet or a more advanced inventory management system.

This allows you to easily determine when you are nearing your reorder point and take appropriate action.

Place orders on time

It is advisable not to delay placing an order until your inventory levels reach a critical low. This can result in stockouts, which have the potential to harm your customer relationships and incur financial losses.

Review your ROP regularly

Over time, it may be necessary to make adjustments to your ROP as a result of shifts in demand, lead time, or safety stock requirements.

Use historical data to forecast demand

To accurately calculate your lead time demand, it is crucial to utilize historical data for forecasting demand. This approach will assist in preventing the overestimation or underestimation of demand.

Consider seasonal variations in demand

If your demand varies seasonally, you will need to adjust your ROP accordingly.

Use safety stock to protect yourself against unexpected events

Safety stock is crucial for protection against unexpected events, such as stockouts at your supplier or a surge in demand. But, at the same time avoid keeping too much safety stock, as this can be costly.

Monitor your inventory levels closely

Regularly monitoring your inventory levels is crucial to recognize when you are nearing your reorder point. This practice will enable you to prevent stockouts and ensure a sufficient inventory supply to meet customer demand.

What is buffer stock?

Buffer stock is a system that purchases and holds stocks to avoid decreasing the price below a target range during good collecting time and releases stock to prevent increasing the price above the target level during the wrong collecting time.

How do you calculate buffer stock?

Click here for Buffer stock Online Calculator

To calculate buffer stock, you need to calculate the following variables. They are

- Desired service level

- The standard deviation of lead time

- Average demand

The formula for Buffer stock is,

Buffer stock = Desired service level X Standard deviation of lead time X Average demand.

Let us have a look at the calculation of variables.

Calculation of desired service level

Service level varies from product to product of an organization. Generally, the service level of an organization’s product lies between 90% to 100%.

Let us assume that your company’s service level is 92%. That is 0.92.

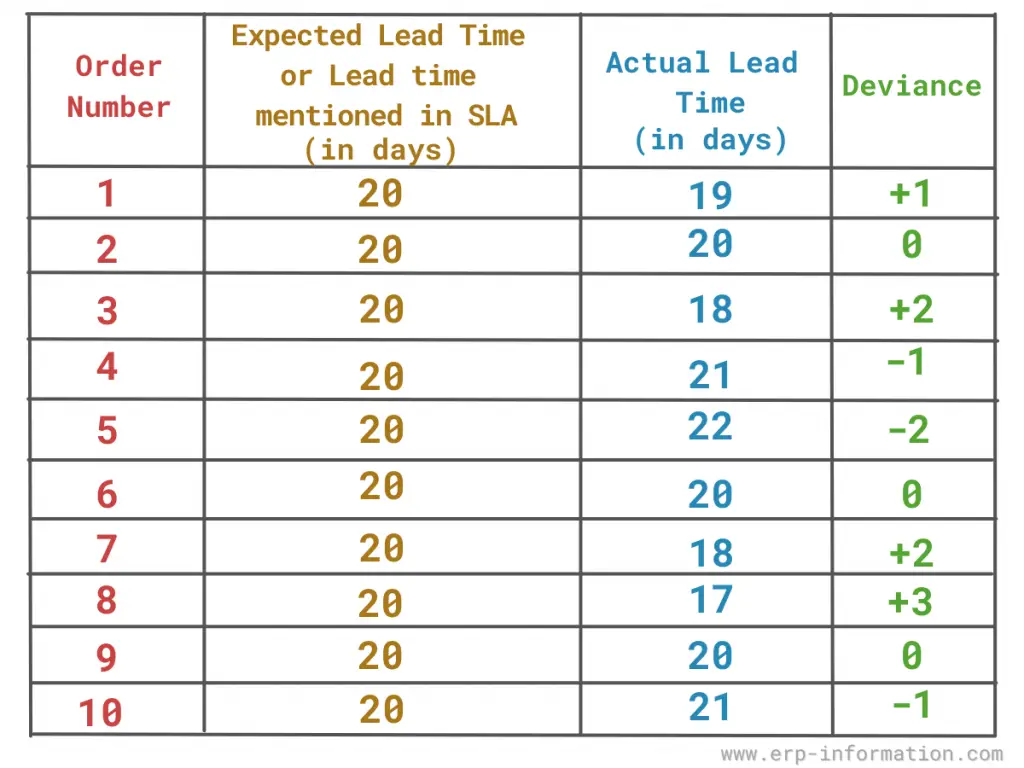

How to find the standard deviation of Lead time?

Historical data is crucial to calculating the standard deviation of lead time. For example, your vendor may have a lead time in their service level agreement. Sometimes this lead time changes.

Some vendors exceed the lead time mentioned in the service level agreement. Some suppliers deliver early.

For example, assume that the lead time in the service level agreement is 20 days. Some suppliers supply after 20 days, and others supply within 20 days.

Now we use historical data to determine the standard deviation of lead time.

First, you need to find the difference between the expected and actual lead times to get deviance (shown in the above table). Then add all the deviance, which is equal to 4 days.

Now, divide it by the number of orders, that is 10. That gives a standard deviation of 0.4. Now add this to the expected lead time.

Twenty days +0.4 days = 20.4 days is your standard deviation of lead time.

- It helps you to calculate accurate buffer stock

- It shows the reliability of your suppliers

Calculation of average demand

To calculate the demand average, you need to determine the number of products you can sell in a given period.

Now assume that you will sell 3000 products in one month. That means 3000 products in 30 days. Then your average demand will be 3000/30 = 10 products per day.

Now your buffer stock = 0.92 x 20.04 X 100 = 1876.8 UNITS

You can integrate it into your reorder point calculation.

Safety stock

Safety stock is the inventory a company holds in its warehouse to avoid a shortage of materials during sudden increasing demands.

It applies to both raw materials and finished final products. If your suppliers supply raw materials on time, your production process does not disturb you.

But in reality, some of your suppliers may not be able to deliver the materials on time because of their problems.

In this case, it is difficult for you to meet your customer’s demands on time. So it is better to have some safety stocks.

To have an undisturbed production process, if you hold more inventory, that is waste only. However, it will be a cost burden to the company since you need to have more space in the warehouse for that excess stock and pay a salary to the laborers handling the inventory.

So, a company must have a good balance between safety stock and overstock. Reorder point helps to maintain this balance.

The efficient periodic review system is vital for reordering points and achieving order-up-to-level inventory control.

FAQs

What sets apart the reorder point from safety stock?

The ROP indicates when to place an order to replenish inventory, while safety stock serves as a buffer for unpredictable demand and lead time uncertainties. While the ROP determines the timing of orders, safety stock acts as a cushion against unexpected fluctuations.

Is a universal reorder point strategy suitable for all inventory items?

Not necessarily. Each inventory item can have distinct demand patterns, lead times, and levels of importance. It is often more effective to customize reorder point strategies to align with the unique characteristics of each product or item in your inventory.

How often should reorder points be re-assessed and adjusted?

The frequency of reassessment depends on the dynamics of your business. Typically, regular reviews are conducted, such as monthly or quarterly. However, it is essential to conduct more frequent reviews for items with volatile demand or suppliers with inconsistent lead times to ensure accurate and optimal reorder points.

Conclusion

Understanding and optimizing the reorder point is not just a theoretical exercise but a practical necessity for businesses aiming to streamline their operations and maintain a responsive supply chain. Implementing these strategies will position your business for greater success and sustainability.