Balancing inventory levels is crucial for business success, yet it’s a delicate balance. Over-ordering results in overstock and higher holding costs while under-ordering risks stockouts and disappoints customers.

One of the inventory management strategies, Order Up To Level is a dynamic formula designed to eliminate inventory guesswork. This approach helps you bid farewell to inventory headaches and confidently manage your stock levels, ensuring operational efficiency and customer satisfaction.

This post explains what order up to level is, its formula, and the difference between order up to level and reorder point as well as reorder quantity.

Evaluate order up to level using our online Order Up to Level Calculator

Find out reorder point using our online Reorder Point Calculator

Evaluate Safety Stock using our Online Safety Stock Calculator.

What is Order Up To Level?

Order up to level is when stock levels are periodically reviewed, and an amount of the item is ordered to return stock levels to the target level.

It is a strategy in inventory management that involves ordering up to the optimal inventory level.

The goal of the order-up-to-level is to have just enough inventory on hand but not too much, which can lead to higher costs and lower profits.

Ordering less than what’s needed may mean running out of product and disappointing customers while ordering more than necessary could result in wasted money or spoilage.

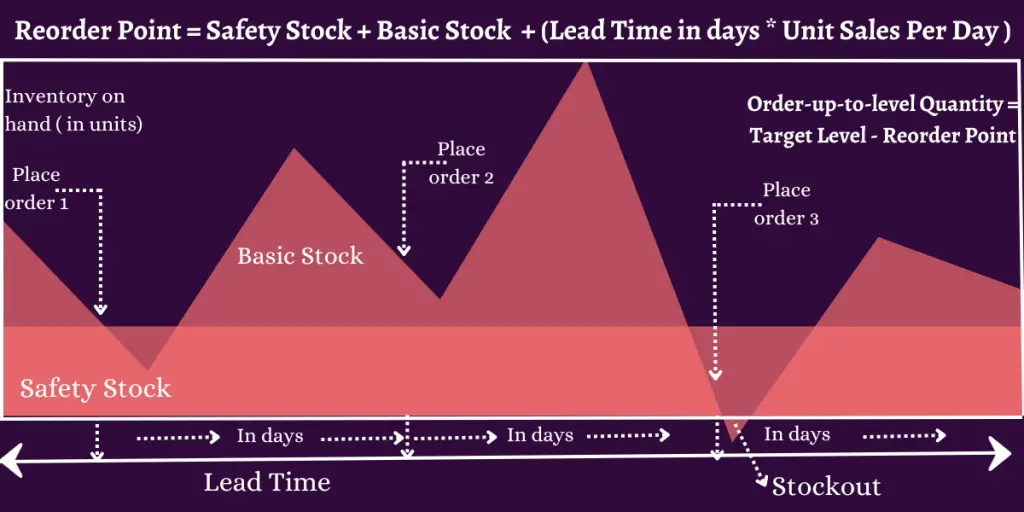

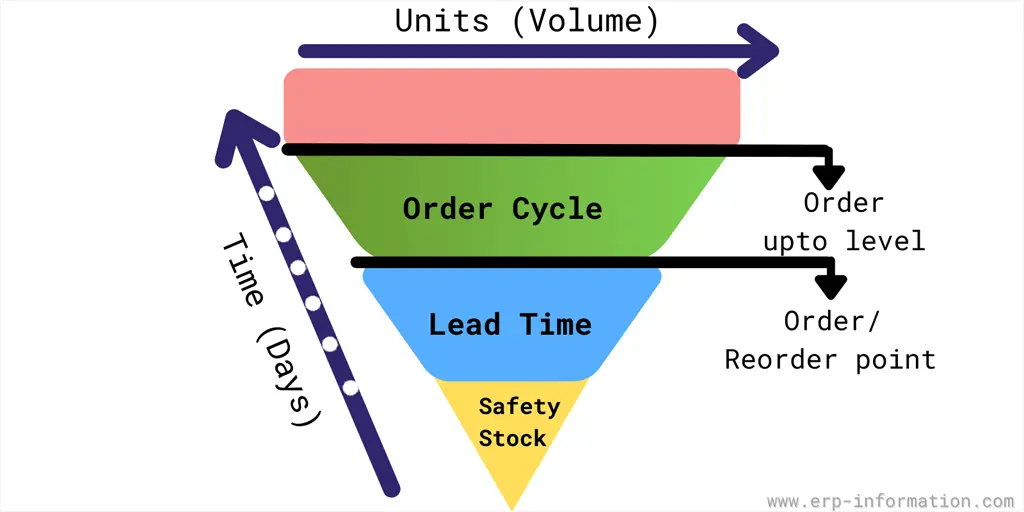

Illustration of Relation Between Order Up To Level and Reorder Point

The order-up-to-level is initiated if the inventory level is at or below the reorder point. In inventory control, periodic stock taking and review will help maintain the order up to level.

Order Up To Level Formula

The most straightforward way of calculating it is,

Order-up-to-level Quantity = Target Level – Reorder Point.

There are two variations we can find in computing reorder points.

- Reorder Point = Safety Stock + Basic Stock + (Lead Time in days* Unit Sales Per Day) when the company maintains safety stock and basic stocks

- Reorder point = (Lead Time in days* Unit Sales Per Day) when the company doesn’t maintain safety stock and basic stocks.

Hence our computation could be,

- Order up to level quantity = Target level – {Safety Stock + Basic stock + (Lead Time in days* Unit Sales Per Day)}.

- Order up to level quantity = Target level – (Lead Time in days* Unit Sales Per Day).

Supply chain management systems available in the market today are with sophisticated inventory management modules.

Most of the ERP solutions available have an SCM module to manage inventory control. The thing that needs to be taken care of is the periodic review system.

Order Up To Level vs Reorder Point

Order up to level and reorder point both are inventory control policies. Minor differences between them are given below.

| Order Up To Level | Reorder Point |

| The stock review is periodic. | Review of the stock is a continuous process. |

| The time interval between orders is fixed. | At the reorder point as soon as the stock drops to the reorder point, a new order will be placed without considering the intervals between orders. |

| In the order up-to-level policy, order quantity varies according to the requirements. | In reorder point policy, the order quantity is fixed. |

Difference Between Reorder Quantity and Order Upto Level

Order Up To Level

- It indicates the level at which a new order is placed to reach the stock level to the target level.

- It determines when the order has to be placed.

- It will be affected by the lead time taken by the vendor to deliver goods.

- It is constant with minimum changes.

Reorder Quantity

- It means the number of items to be ordered to fulfill the target level.

- It determines how much quantity has to be ordered.

- It will be affected by the shipping cost and discounts.

- It may vary for each order.

FAQs

How do you calculate the reorder level?

We can calculate the reorder level by multiplying average demand with lead time and adding safety stock.

That means, Reorder level = (Average demand X Lead time) + Safety stock

What are the factors affecting the reorder level?

The determination of the reorder level is influenced by several factors, including a company’s work-order lead time, the demand it encounters within that timeframe, and the decision to uphold a safety stock.

Work-order lead time signifies the duration required by the company’s suppliers for the production and delivery of the requested units. It is crucial to accurately pinpoint the appropriate reorder level, as this has a significant impact on inventory management effectiveness.

Why reorder level is important?

The significance of a reorder level lies in its pivotal role in maintaining efficient inventory management. It serves as a vital safeguard against incurring excessive holding costs and the pitfalls of stockouts, overstocking, and potential lost sales, guaranteeing a constant and appropriate stock supply within your inventory.

Conclusion

Order up to level strategy of inventory management helps company to purchase precisely what it needs for the upcoming period. This proactive strategy effectively mitigates the risk of surplus stock and insufficient customer demand.

Moreover, ordering up to level serves as a safeguard against potential disruptions, such as sudden spikes in customer demand, ensuring uninterrupted supply without resorting to backorders or shortages.

We hope this article has given you some new insights into managing your inventory more efficiently.