In the world of inventory management and logistics, “planned order receipt” is crucial for businesses. This key concept ensures that when a company orders materials or products, they arrive precisely when needed.

This article will help you understand the planned order receipt, its real-life examples, and calculations. All to help businesses stay organized and keep their supply chains running smoothly.

Definition

A planned order receipt is a future projected receipt based on the generation of a planned order that has not yet been firmed into a scheduled receipt.

In businesses, “planned order receipt” refers to the strategic scheduling and control of when materials or products are expected to arrive. It’s a critical aspect of inventory management and supply chain logistics, ensuring that items are received precisely when needed.

By planning the receipt of orders carefully, businesses can optimize their operations, minimize inventory costs, and maintain a smooth and efficient supply chain.

This practice involves calculating the right quantity, lead times, and order points to keep the flow of materials or products consistent and avoid shortages or overstocking.

In a planning schedule, planned order receipts are also known as planned receipts, released orders, or released MPS.

What is a planned receipt?

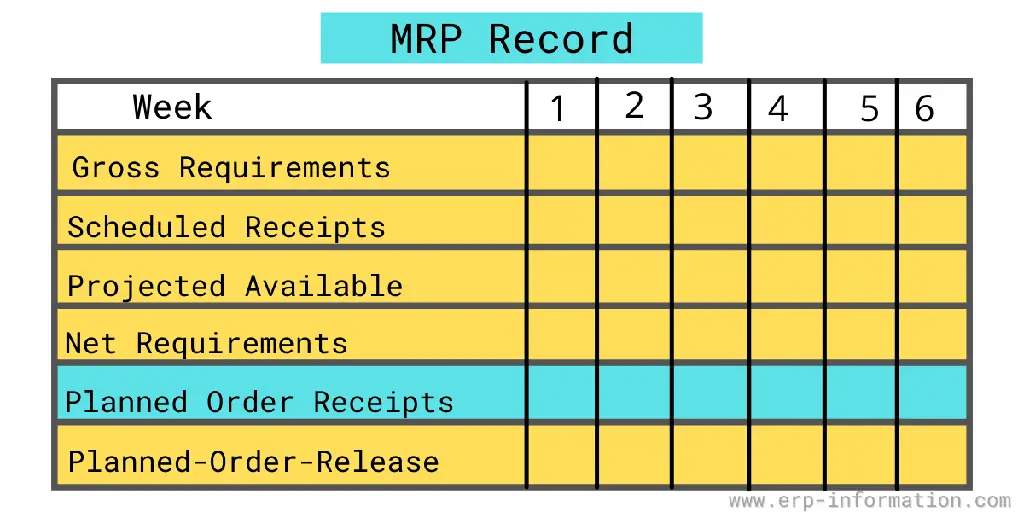

Planned receipts are a part of Material Requirements Planning (MRP) and help determine the amount that needs to be ordered at any given time.

In addition, they consider what’s left in stock and those items scheduled for arrival later on during certain transitory phases, so you’ll know when your order will arrive!

Previously ordered receipts are also scheduled to arrive and thus need to be added to the MPS (Master Production Schedule) during that period.

The available inventory stock added to the scheduled receipts of materials due and then netted from the gross requirements gives us the value for net requirements.

That is a value that quantifies the units required for the next fence. The projected available balance is the balance projected into the future as the number needed of inventory remaining can even be negative.

Planned order receipt calculation

Planned order releases are mainly based on whether the projected available is negative or below zero, which means all the inventory has been used up, and more needs to be ordered.

A planned order receipt gives a date on which to expect an order. If the projected available is zero or is more than that of a specific safety stock value, there is no requirement to put in a planned order release.

When a planned order is released, it is always a confirmed order because it has been calculated after netting off the inventory. Thus it is not similar to the anticipatory order releases.

A planned order release meaning is always about a much more confirmed event. Hence, it is controlled by an MPS, a computer-generated program that maintains a schedule and keeps a tab on the planned orders.

The MPS will not put any further order if the projected available balance is zero during a fixed time fence. But once the period is over, it will generate an order after netting and evaluating the on-hand inventory.

Planned order receipt example

Let us take an example of a scenario of creating a planned order receipt in a factory that needs a certain kind of material.

The on-hand inventory present at a given moment is 40, and the demand for the first week is 45. Now, as the demand is more than the projected balance, the entire balance is used up with five more units.

That makes the projected available balance for the next week negative (-5). So now, as the projected balance is negative, an MPS is released of 60 units, making the balance 55. This MPS release is known as a planned order release.

This week, there is a demand for 40 units. That makes the projected available as 15. The projected availability is now positive, so no MPS is required to be released.

Hence, MPS is 0. The date on which the planned order is due is therefore known as the planned order receipt. Thus planned order releases are always equal to planned order receipts in quantity.

FAQs

What is the difference between planned order receipts and scheduled receipts?

The difference is that the planned order receipt is a receipt for a planned order that has not yet been released. The scheduled receipt is a receipt for a released order.

What is the difference between planned order receipts and planned order releases?

The difference is that the planned order receipt indicates the date on which the order needs to be received, whereas the planned order release indicates the date on which the order needs to be placed to receive the goods on time.

In other words, The planned order receipt signifies the arrival of materials, while the planned order release represents the commencement or approval of the process.

Conclusion

Planned order receipt is a fundamental component of effective inventory management and supply chain logistics. It ensures that businesses receive materials or products exactly when they are needed, preventing shortages and excess inventory.

By carefully planning and calculating order quantities, lead times, and order points, businesses can operate more efficiently and cost-effectively. Real-world examples demonstrate how this concept works in practice.

Understanding planned order receipt empowers businesses to maintain a well-organized and efficient supply chain, ultimately contributing to their success in the competitive marketplace. We hope this article was helpful to you!