Effective management of inventory is crucial for businesses across various industries. One critical aspect of this is understanding the projected available balance (PAB), a vital metric that helps companies anticipate their future inventory levels.

Projected available balance (PAB) is an essential concept in inventory management. In simple terms, PAB is the amount of inventory projected to be available for use shortly.

By accurately forecasting PAB, businesses can strike the perfect balance between meeting customer demand and optimizing inventory costs.

This article will discuss PAB, its formula, examples, and how it can improve inventory management.

Projected available balance definition

It is defined as the balance projected in the future, as the available balance of the on-hand inventory. It is derived after netting the requirements and adding the scheduled receipts and planned orders that are about to arrive.

An MPS will be released when the projected availability is determined and how much inventory is left. If the projected available balance.

- Is more than zero

- Or equal to zero

No net requirement exists, and thus MPS is not released. That is because the available balance is substantial, and the demands for the next batch could easily be met with it.

If the projected available balance were less than zero, there would only be a release from the MPS according to a specified lot size.

An MPS is also known as a planned order schedule. This lot size is specified, keeping in mind the company’s gross requirements and regular proceedings.

Projected available balance formula

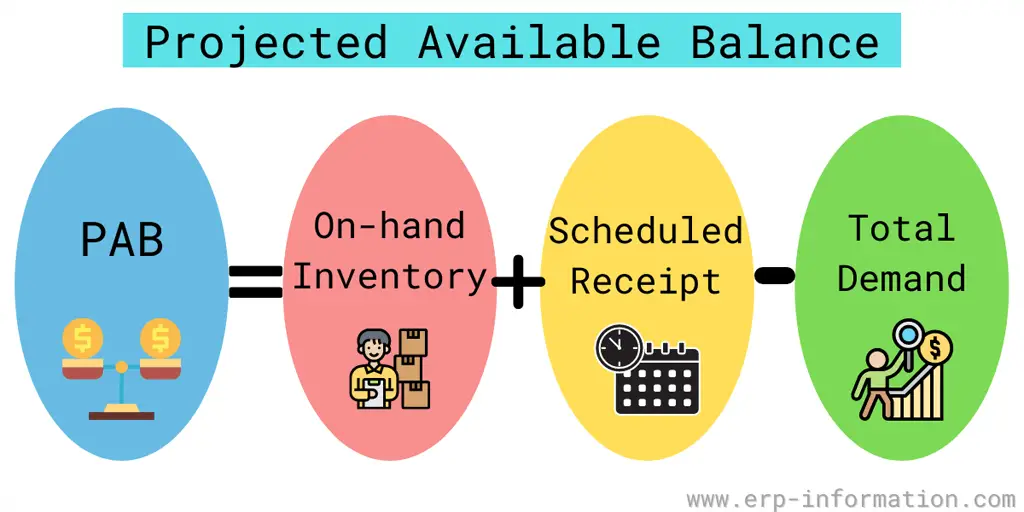

The projected available balance is calculated using the general formula

(on-hand inventory) + (scheduled receipt) – (Total demand)

Projected available balance example

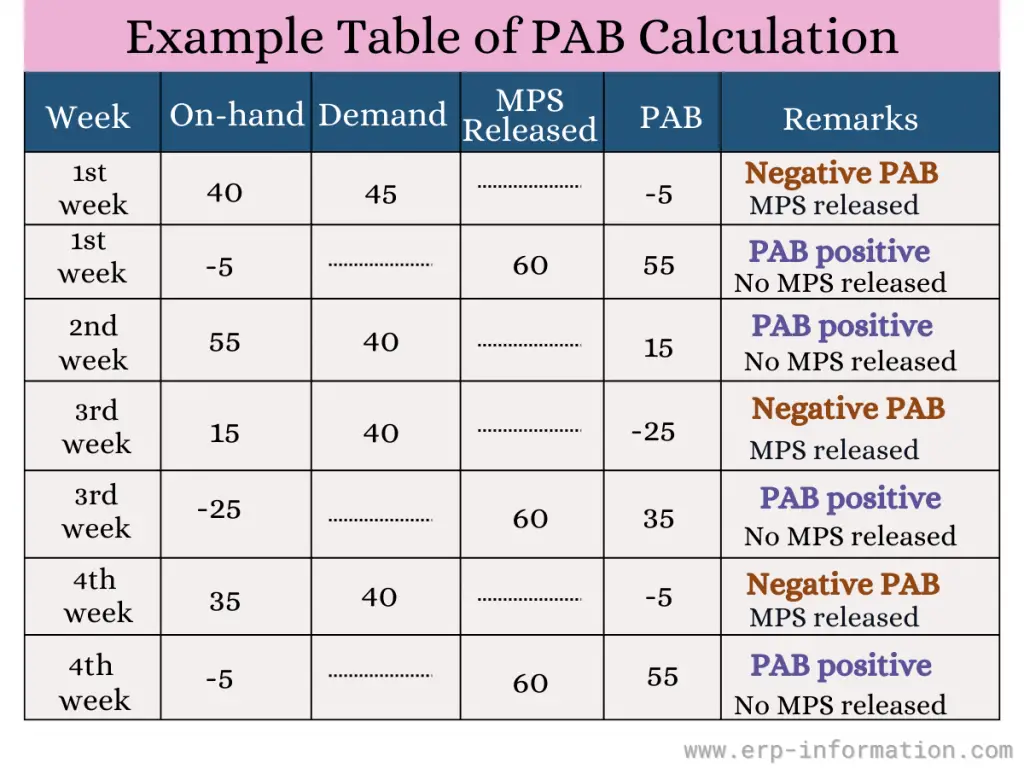

Below is the PAB calculation example.

A company generally has a lot size of 60 units.

The on-hand inventory present at a given moment is 40.

The demand for the first week is 45.

Now, as the demand is more than the projected balance, the entire balance is used up with five more units.

That makes the projected available balance for the next week negative (-5). So now, as the projected balance is negative, an MPS is released of 60 units, making the balance 55.

Now, this week, there is a demand for 40 units. That makes the projected available as 15. The projected availability is now positive, so it does not require any MPS to be released. Hence, MPS is 0.

In the coming week, a scheduled release of 60 units has already been set up from before.

That makes the next projected available as 60 +(15-40) = 35.

The balance will be used up in the next week. There is already a demand of 40 and a scheduled order of 60.

Hence the projected available is 60+(35-40) =55.

These 55 units are now available for the next week as an on-hand inventory.

What is MPS?

An MPS or Master Planning Schedule is a computer-based program that maintains orders for a firm. It keeps a tab on the orders scheduled to arrive and how much is to be ordered.

An MPS also maintains a clear schedule of the projected available balance, scheduled receipts, planned releases, etc., and does not allow any order to be placed when the projected available is 0 within a given time fence. But once outside the time fence, it will automatically order if the projected available is negative.

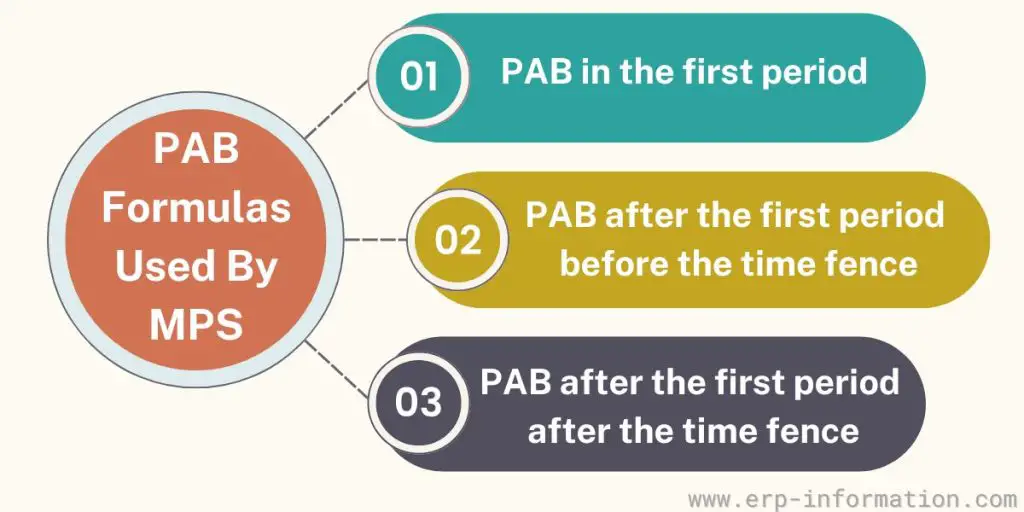

The formulas used by an MPS

The projected available balance calculator can use the below rules for its calculations.

Projected Available Balance (PAB) in the first period = Current on-hand inventory + MPS Receipts – Safety Stock – Orders

Projected Available Balance (PAB) after the first period before the time fence = Prior period PAB + MPS receipts – Customer Orders.

Projected Available Balance (PAB) after the first period after demand fence = Prior period PAB + MPS receipts – Greater Forecast/Customer Orders.

Benefits of MPS

- It helps to prevent stockouts.

- It helps balance demands, the equipment’s capacity, and the laborers’ requirements.

- It gives a clear picture of the number of products manufactured in a given period.

- It helps to improve efficiency.

- With rough-cut capacity planning, it helps to find the real capacity to meet customer demands.

Hence, the MPS is a master planner which efficiently keeps track of the order schedule.

FAQs

What is the projected on-hand inventory?

On-hand inventory refers to the number of physical units of a particular product a company has in its possession at a given time.

This can include finished goods ready to be shipped to customers and raw materials and components used in the production process.

The on-hand inventory figure is vital for businesses because it represents the number of available products to meet customer demand.

The projected on-hand inventory formula estimates the amount of inventory a company will have at a given point in time.

This formula considers the company’s sales, production, and lead time. Lead time is the time between when an order is placed and when it is received.

The projected on-hand inventory formula is

(average daily sales x lead time) + safety stock – average daily production.

What are the common challenges businesses face in managing PAB, and how can they overcome them?

Challenges include demand fluctuations, lead time variability, and changing market conditions. To overcome these, businesses can adopt agile supply chain strategies, use real-time data, and maintain strong supplier relationships.

Can Projected Available Balance be used in different industries and not just retail?

Certainly, it’s applicable in various industries like manufacturing, healthcare, and distribution, where inventory control and demand forecasting are crucial for operational success.

What software or tools are available for businesses to manage Projected Available Balance effectively?

There are many inventory management and Enterprise Resource Planning (ERP) software solutions available, such as SAP, Oracle, and various cloud-based platforms, that offer features for managing Projected Available Balance.

Conclusion

PAB is an essential concept in inventory management and should be considered when purchasing decisions. By understanding your projected available balance, you can ensure that you are not overstocking or understocking inventory.