Scheduled receipt is about anticipating the arrival of essential supplies, and ensuring the show goes on smoothly.

Scheduled receipts refer to a purchase order processed by a vendor but have not been closed out. This means that any goods purchased on this purchase order have not yet been received and paid for. In other words, they are “scheduled” to be received at some point.

In this article, you will get a clear picture of the scheduled receipt, an example of a scheduled receipt, and its role in MRP management.

What is a scheduled receipt?

A scheduled receipt is items to be received in a particular period. (An open order that has an assigned due date).

It is like an old order about to arrive at a specific date. So the company keeps a tab on the scheduled arrivals of the required materials, primarily raw materials necessary for the manufacturing unit’s functioning.

Scheduled receipts are a component in the Materials Requirements Planning or MRP, and a column lists each element’s date of scheduled arrival.

It also mentions the quantity that is due for each component. This information is used to calculate the MRP, and thus the net requirements of raw materials are summed.

Example of scheduled receipt

A small company of handmade chocolate is highly famous and has a high demand. The company prepares ten cartons of chocolates every month.

For that, it requires 50 kilograms of flour every month. However, due to festivities, there was an increased demand for chocolate in a particular month. So the company used all the flour available and sold all the chocolates.

They also ordered 20 kilos of flour from the supplier, which was scheduled to arrive two weeks later.

Now in the next month, we calculate the net requirements. But, first, the combination of on-hand and scheduled orders is added and subtracted from the gross need of 50 kilos.

Since all the flour was used up, the available balance of flour was zero. Hence net requirements of flour in the next month will be

50 Kilos – 20 Kilos = 30Kilos.

Now, imagine the company has used up all the flour, and there were 30 kilos of flour from a backorder that was also consumed. What will be the net requirement for the next month?

As the company had consumed more than the gross,

50 kilos -(-30 kilos +20 kilos) = 60 kilos

will be the net requirement in the coming month.

The net requirement of a company is also known as the planned order receipts, and it is determined only after netting the available and scheduled arrivals from the gross.

The result of this netting is also known as the projected available balance. If the projected available balance is equal to the specified safety stock or more than the specified safety stock (in case flour consumption in one month exceeds the gross), no net requirement is planned.

However, a planned order is generated if the projected available balance is less than the specified safety stock. The MRP system maintains the planned order schedule, also known as planned order receipts. It is only generated after considering all the scheduled receipts and on-hand stock dated to the crucial period.

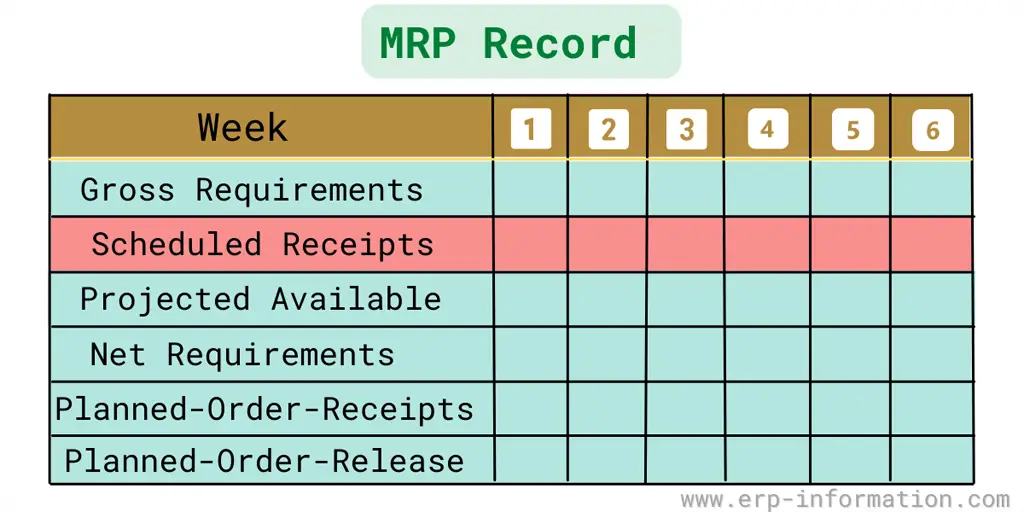

Scheduled receipt in MRP management

Material requirement planning is a part of production planning, and it is also a stock control system. It helps to keep a balanced inventory and provides required materials when needed.

MRP requires three primary inputs to function correctly. They are master production schedules, inventory status records, and product structure records.

The main objectives of MRP are

- Keep the lowest possible inventory

- Check the availability of components, materials for production, and products for dispatch.

- Plan purchase activities, manufacturing activities, and delivery schedules.

Scheduled receipts are integral to materials requirement planning, a computer-based inventory, and a planning control system.

Scheduled receipts in MRP are highly efficient in systems with complex procedures, complicated billing systems, and multiple processing steps.

MRP ensures that all the required materials are present in proper quantities and at all times, thus ensuring the smooth functioning of the system.

Other integral parts of material requirement planning are

- Gross Requirements: These are the requirements needed during every period

- Available Balance: Balanced inventory at the end of each batch

- Net Requirements: Needed to meet requirements and safety stock

- Planned Order Receipt: It arrives at the beginning of the period

- Planned Order Release: It addresses lead time

We also provide an online calculator to calculate

FAQs

How does a scheduled receipt be different from a planned order release?

A scheduled receipt is a planned receipt for order replenishment recorded at the beginning, whereas a planned order release is a release of a planned replenishment order by the material planner.

A scheduled receipt is when a supplier agrees to deliver a specific inventory quantity at one particular time. On the other hand, a planned order release is when a supplier agrees to release a specific quantity of inventory at a particular time.

The critical difference between scheduled receipts and planned order receipts is that the customer (or retailer) has agreed to take possession of all or most of the inventory at one time with a scheduled receipt. By contrast, with a planned order release, the customer only takes control of part of the inventory at one time and leaves the rest for later.

Conclusion

Unscheduled or open purchase orders are a red flag for any business. They represent part of your revenue that is unaccounted for, but they also require more resources to manage and handle over time.

Therefore it’s essential to know the difference between unscheduled and scheduled receipts to ensure all purchases are accounted for to maximize profit margins.