Ensuring a smooth and uninterrupted supply of raw materials is essential for maintaining efficient production processes and meeting customer demands. Vendor scheduling plays a critical role in this aspect, acting as a bridge between demand forecasts and actual production needs.

This blog will discuss the concept of vendor scheduling, exploring its definition, importance, benefits, and the step-by-step process involved.

Definition

In business, Vendor Scheduling can be defined as the process of communicating with suppliers to ensure that you have the necessary raw materials for an agreed period.

It is a critical component of supply chain management, and it requires careful planning to ensure that your customers’ confirmed demand is met.

Vendor scheduling is done through rigorous planning that considers the demand forecasts and shipping schedules that only evaluate the customers’ confirmed demand. Vendors or suppliers are then contacted to ensure a continuous supply of raw materials. Vendor scheduling ensures timely delivery of raw materials used in the production process.

The Importance of Vendor Scheduling

It is crucial for several reasons:

- It ensures that you have the raw materials necessary to meet customer demand.

- It allows you to plan your production schedule more accurately, leading to improved efficiency and reduced costs.

- It helps to ensure that you have a continuous supply of raw materials, which can help to avoid production delays.

Benefits of Vendor Scheduling

- It helps to provide accurate shipping information to your vendor

- It allows you to identify both short and long-term requirements for purchased items and will enable vendors to plan their manufacturing and shipping schedules

The Process of Vendor Scheduling

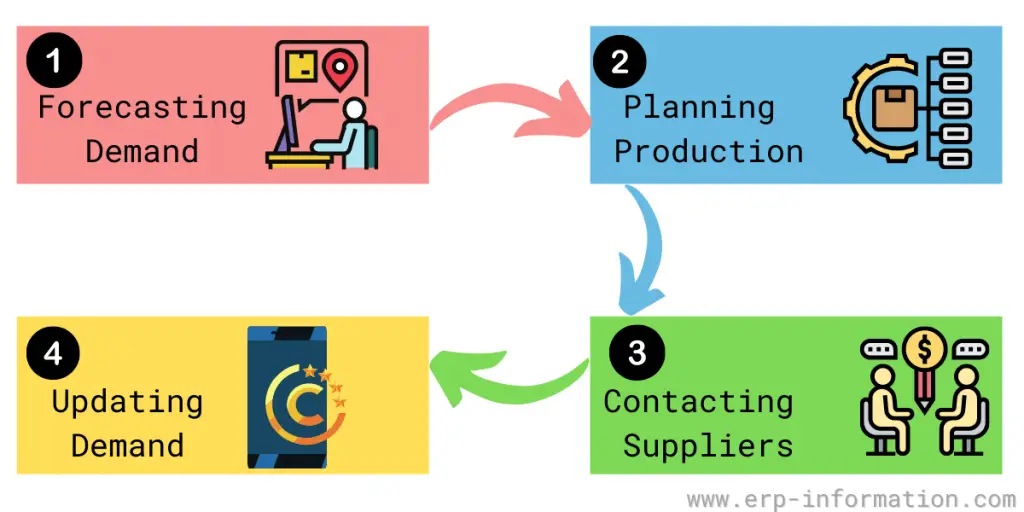

The process typically involves the following steps:

Forecasting demand

First, to plan effectively, you need to understand your customer demand accurately. This can be done through historical data analysis, market research, and other methods.

Use our free online calculators to forecast demand

Planning production

Once you have an idea of the demand for your products, you need to plan your production schedule accordingly. This includes determining the necessary raw materials and calculating how much each material will be required.

Contacting suppliers

Once you have a rough idea of your raw material requirements, you need to get in touch with your suppliers and communicate the details. Vendor scheduling typically involves creating a Vendor Schedule (VS), which is then sent to each supplier along with an order confirmation number.

Updating demand

As customer orders come through, they need to be confirmed and added to the Vendor Schedule. This will help to ensure that your production schedule is as up-to-date as possible.

What is a vendor?

In the supply chain, a vendor is a business entity that provides goods or services to consumers and will be paid for that.

Many people get confused about vendors and manufacturers. Of course, both parties have different roles, but they often overlap when the same company does both tasks at once (as happens with some significant manufacturing firms).

More on supplier scheduling

Supplier scheduling is done through rigorous planning that considers the demand forecasts and shipping schedules that only evaluate the customers’ confirmed demand.

The data is gathered from several internal verticals, such as the purchasing department, and forecasts as predicted by the planning department.

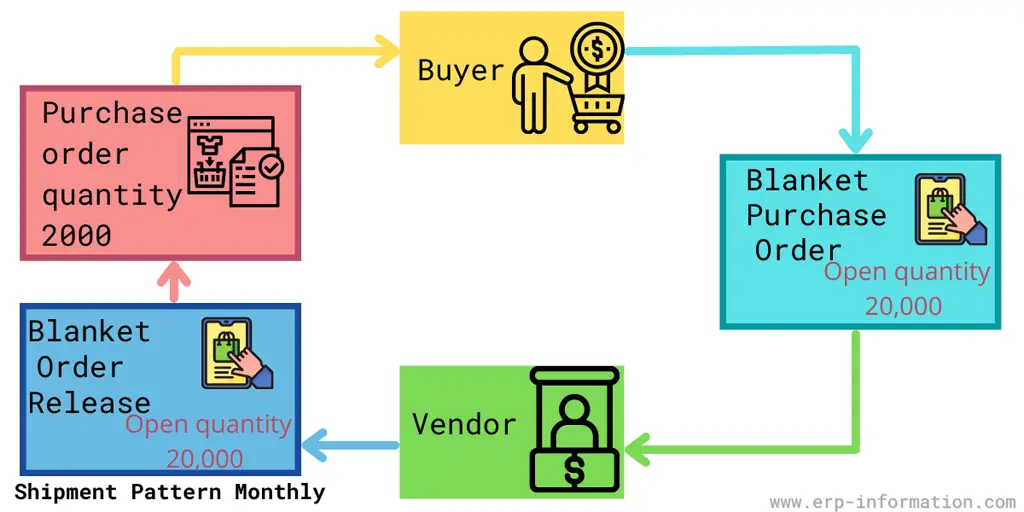

A supplier scheduling system is a contract where the business will provide schedules instead of hard copies of the purchase orders.

Supplier scheduling includes the following tasks:

- Defining vendor schedule

- Creating vendor schedule

- Updating vendor schedule

- Releasing vendor schedule

- Printing vendor schedule

The schedule can vary from weeks to months for a specified financial year.

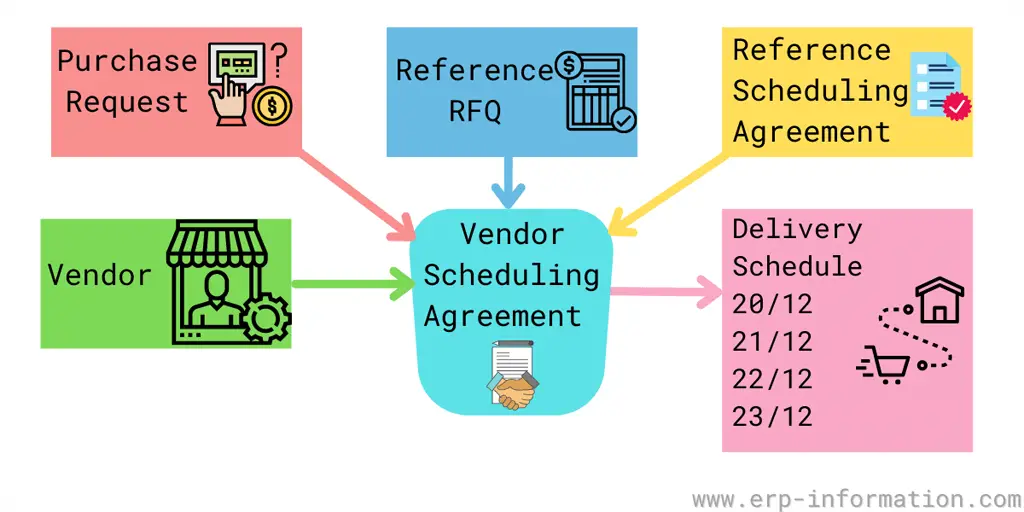

Vendor Scheduling Agreement

What is a vendor scheduling agreement?

A vendor scheduling agreement is a purchase agreement made with the vendor that tie-ups the vendor for providing materials under pre-agreed conditions.

This agreement contains the quantity and delivery date of the material or item required by the buyer.

The vendor scheduling agreement also contains the procurement type of each item. Those procurement types are stock transfer, consignment, standard, and subcontracting.

The entire quantity of items mentioned in the vendor scheduling agreement to be delivered is getting over a period in the delivery schedule.

That is mentioned in terms of lines and indicates each item’s planned delivery date.

If items in the scheduling agreement are subcontracting, you can mention those items to be provided to the subcontractor regarding one and all scheduled delivery of the ordered item.

Conditions can be applied to the whole scheduling agreement. However, requirements at the item level will be applied particularly to the item to be delivered in each case.

The scheduled agreement’s release is issued to the supplier and specifies the material delivery on the date shown.

The cost of the item can be allocated through the account assignment. Finally, the supplier can confirm the customer organization, specifying their consent with the scheduled delivery date.

Vendor Scheduling Software

Following are the 12 best software that helps schedule and manage the vendor. Some of them are free software.

- SAP Ariba

- SAP Feildglass

- Vanta

- Airbase ( free software)

- Oracle Procurement Cloud

- Genuity( free software)

- Blissfully(free software)

- Tradeshift

- Productive

- Onspring

- Gatekeeper (free software)

- Precoro(free software)

FAQs

What do you mean by scheduling?

Scheduling is a technique of planning your work to reach your objectives within a given time. When you schedule your work appropriately, it increases your efficiency.

Conclusion

Vendor scheduling is a vital process that helps businesses stay ahead by ensuring a steady supply of raw materials and reducing production delays.

By accurately forecasting demand, planning production, and maintaining clear communication with suppliers, companies can significantly improve their efficiency and cost-effectiveness.

Understanding and implementing effective vendor scheduling practices can lead to smoother operations, better product quality, and higher customer satisfaction.

Hoping this read is worthwhile!