Predicting and managing demand is a maze in the ever-fluid business world. This article aims to illuminate this complex process known as Demand Planning.

It is the backbone of effective supply chain management and is a critical aspect of any business, large or small.

This article looks at the basics of demand planning, its importance, processes, best practices, methods, and the difference between demand forecasting and planning. It also introduces the role of a demand planner and discusses SAP IBP and SAP APO DP.

What is Demand Planning?

It is the process of predicting the need for a product or service.

It usually analyzes historical data to identify patterns. This data is then used to create a requirement forecast.

Companies can use the demand forecast to help plan production and inventory levels. The company can also use it to decide on pricing and marketing strategies.

Demand planning is integral to supply chain management and can help ensure that products and services are available when customers need them.

Businesses can forecast orders in the short-term, medium-term, and long-term.

Short-term means less than one year; it includes seasonal sales like holiday shopping around the same time of year (for example, Thanksgiving and Christmas).

Medium-term is between one and two years into the future.

Long-term refers to anything more than two years away from now.

Related Terminologies

Below are a few related terminologies you need to know before proceeding further.

Demand management

Demand management is forecasting demand and then planning and managing the production and distribution of goods and services to meet those orders.

It’s a critical part of any company’s operations, and it’s significant for supply chain managers, who need to ensure that they have the right amount of stock on hand to meet customer demand.

Demand plan

It is a comprehensive guide that outlines the demand for a product or service. It can help businesses better understand their customers’ needs and forecast later needs.

It can also help businesses optimize their supply chain and ensure enough products to meet customer orders.

Future demand

One of the most important aspects of demand planning is predicting future demand. This can be done in various ways, such as by analyzing historical data, considering market trends, and examining consumer interests.

Understanding future demand is crucial to adequately plan for it and ensure that your supply chain can meet needs. You can make better production planning, inventory control, and marketing decisions with accurate forecasts.

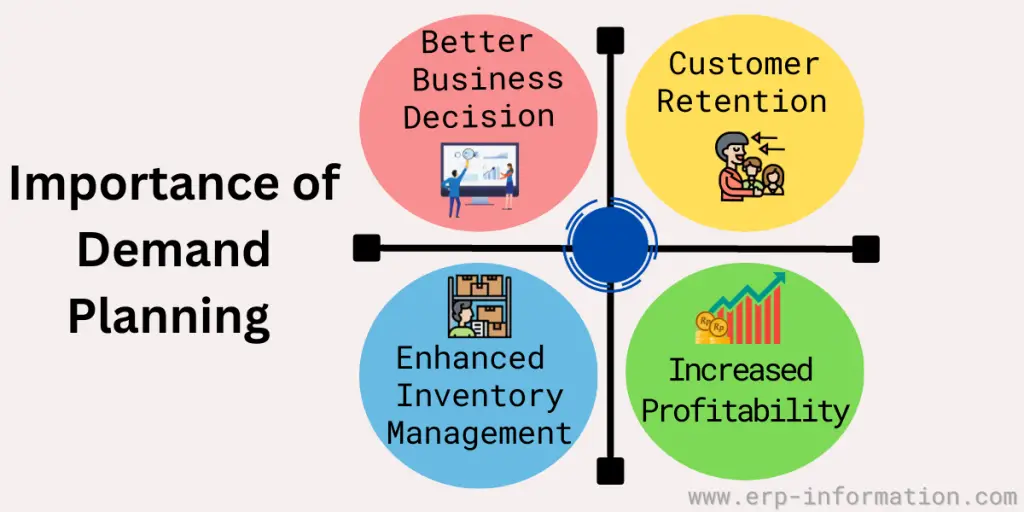

Importance

It is essential because it helps businesses understand and forecast customer demand. This information can decide what products to produce and how many to keep on hand.

It also helps businesses identify trends and change their manufacturing or marketing strategies accordingly.

Demand planning helps businesses in many ways.

- Improved inventory management: Demand management helps forecast demands so businesses can avoid stockouts or overstock situations.

- Increased profitability: Businesses can increase their profitability by avoiding stockouts and overstock and optimizing production schedules.

- Improved customer satisfaction and retention: Businesses can improve customer satisfaction and retention by meeting customer demand more consistently. That helps to retain the customers.

- Better business decisions: Demand planning can help businesses make more informed decisions about pricing, marketing, and product development. For example, if a company knows that demand for a particular product is expected to increase, it can adjust its pricing or marketing strategy accordingly.

Here are some specific examples of how demand planning can be used to improve business performance:

- Retailers can use it to ensure they have the right amount of inventory for the upcoming holiday season. That can help to avoid stockouts and lost sales.

- Manufacturers can optimize their production schedule and avoid overproducing goods that may not sell using demand planning.

- A restaurant can use it to forecast the number of customers it will likely serve on a given night. That information can be used to adjust staffing levels and ensure enough food is on hand.

Elements of Demand Planning

Trade promotion management

Trade promotions can have a significant impact on demand. Demand planners need to work with the marketing team to forecast the impact of trade promotions like in-store giveaways or discount pricing on demand.

Product portfolio management

The product portfolio can also impact demand. Demand planners need to work with the product management team to understand the influence of new products on other products’ demand to increase the market share.

Statistical forecasting

With the help of historical data, statistical forecasting generates advanced statistical algorithms for supply chain forecasting. Businesses can assess seasonal demand with the help of statistical forecasting.

Demand Planner

A demand planner is a professional who estimates the future demand for a product or service for an organization using analytical and sales data. Demand planners work closely with the sales and marketing teams to develop and produce forecasts and models to predict future demand.

Demand Planner Skills

They are responsible for creating plans. They work with the supply network planning module to forecast orders and create a plan to meet them. They are also responsible for creating a market plan.

A demand planner typically requires several skills to manage forecasting and planning effectively. These skills include:

Data Analysis: A strong understanding of data analysis is essential to accurately analyze past trends and forecast future demand.

Strategic Thinking: The ability to think strategically about inventory management, forecasting, and supply chain planning is key for any successful demand planner.

Problem-Solving: Quickly identifying issues in the supply chain is an important skill for any demand planner. That can help them identify solutions to ensure stock levels are maintained efficiently.

Communication: Good communication skills are essential for planners to effectively collaborate with other departments such as sales, marketing, operations, and finance to gain the necessary insight they need.

Automation: The planner should be able to use automation tools, such as supply chain management software and demand planning software. He should also know how to work with Enterprise Resource Planning (ERP).

Demand Planning Methods

Demand planning works on two principles, that is, push and pull. In the push method, the manufacturer will assume that if he produces the product, the customer will come and buy (if we build it, they will come).

The drawbacks of this method are sometimes products will not be available to fulfill the demand, and other times, products will be in the warehouse because of less demand.

That affects the cash flow of the business. It is very difficult to balance supply and demand in this method.

Nowadays, demand planner uses the “pull” method. In this method, the demand planner gathers information on customer demand.

Therefore, it is essential to have an accurate forecast of customer demand. Otherwise, this method also leads to the same problem as the push method.

How do demand planners use forecasting to develop demand plans?

Demand planners use predictions to develop plans by analyzing demand history and predicting later requisitions.

They also use market research to get a better understanding of customer demand. This information is used to create a plan to help the company meet its sales goals.

Following are the various methods to get an accurate forecast of customer demand.

- Regression analysis – Linear regression helps to put previous demand levels in the least square statistical model and predicts future demand.

- Seasonal trends – It predicts future demand based on historical sales data of a particular season.

- Average demand – It considers the average demand of the last few sales.

- Sales forecasting – It predicts future demand with the help of sales opportunities.

They also use market research data to understand customer orders and forecast specific product categories.

Demand Planning vs Demand Forecasting

| Demand planning | Demand forecasting |

| It is the course of action taken to meet or exceed those forecasts. | It predicts future events. |

| It takes specific actions such as stocking up on inventory or increasing production. | It estimates future levels of some measurable quantity based on past data. |

| It is used to predict the need for a product or service. | It is used to generate demand plans. |

Ultimately, demand forecasting is the foundation for overall demand planning.

Key Steps of the Demand Planning Process

It can be divided into three major phases: forecasting, production scheduling, and marketing intelligence.

1. Forecasting

In this step, you need to estimate later needs for your products or services. This can be done by analyzing past sales data, market trends, and other factors that may affect the market.

2. Production Scheduling

In this step, you need to plan how much product to produce and when to make it. You’ll also need to determine what resources to create the product and schedule those resources accordingly.

3. Marketing Intelligence

It is the final step in the planning. You’ll need to collect and analyze market and supply information in this step.

You will then use this information to adjust requisition forecasts, schedules, or inventory levels if needed.

Best practices

1. Define clear goals and objectives for your demand planning process.

2. Collect data from your organization’s relevant sources, both internal and external.

3. Use that data to develop accurate forecasts for future product demand.

4. Plan for potential disruptions in supply or demand that could impact your business goals.

5. Take action based on your forecasts to ensure that your products are available when and where they are needed most.

SAP IBP

SAP integrated business planning is a cloud-based advanced planning tool that helps plan demand for products and services.

It is one of the many SAP modules and part of the SAP Advanced Planning group of products.

The main features of SAP IBP

- Sales And Operations Planning

- Real-time planning

- Simulation and comparison of scenarios

- Collaboration

- Performance monitoring

- Forecasting and Demand management

- Demand planning

- Advanced demand sensing

- Robust statistical models

- Time-series analysis

- Inventory planning and optimization

- Multistage inventory optimization

- Robust statistical models

- Forecast error management

- Embedded analytics

- Response And Supply Planning

- Multilevel planning

- Supply planning

- Rough-cut planning

- Response management

- Demand -Driven Replenishment

- Smooth material and information flow

- Replenishment based on actual demand

- Calculation of decoupled inventory buffers

- Supply chain resilience

- Supply Chain Visibility

- Intelligent visibility into your supply chain

- Simulation and comparison scenarios

- Event-driven exception management

- Supply network collaboration

Organizations can use the tool to evaluate different scenarios and better meet customer requirements. The tool also helps businesses align their supply chains with their business goals.

SAP APO DP in SAP SCM

SAP Advanced Planner and Optimizer(APO) demand planning is an on-premises software that predicts upcoming demand and helps to optimize the supply network. SAP DP accomplishes this by integrating requisition data with supply network constraints.

key features of SAP APO DP

- Planning

- Supply network planning

- Management

- Estimation

- Sales and operations planning (S&OP)

- Production planning

- Inventory control

- Demand shaping

- Demand sensing

SAP APO shortcomings

SAP APO has a few disadvantages, including the following:

- SAP DP can be expensive to implement

- It can be challenging to use

- SAP APO can be time-consuming to set up and configure

Future of Demand Planning

With the development in technology and Artificial Intelligence (AI), demand planners will likely be able to rely more heavily on automated processes such as demand planning software. That can help make forecasting and inventory planning easier, faster, and more accurate.

AI will be able to analyze large amounts of data in real-time, making it easier for planners to identify trends and accurately predict customer needs.

Other techniques, such as machine learning, will also play a role in helping planners better anticipate customer demands by giving them access to predictive analytics that they could use to make informed decisions.

Additionally, using the Internet of Things (IoT) will allow planners to gain insight into customer behaviors from connected smart devices, allowing them to adjust their forecasts accordingly.

FAQs

What is SAP APO in supply chain planning?

SAP Advanced Planning and Optimization (SAP APO) is an SAP ERP software solution module that enables companies to optimize their orders and supply chain processes. It helps organizations’ business processes better forecast the market, allocate resources, and synchronize production with the requisition.

Does SAP IBP replace SAP APO?

No, SAP IBP and SAP APO demand planning are two different solutions that can be used together to optimize the SAP demand planning process. SAP IBP is a newer solution that provides a more intuitive interface and enhanced features. At the same time, SAP APO is a more established solution related to SAP SCM that offers more comprehensive functionality.

What is SAP APO SNP?

It is a module of SAP that enables you to optimize your supply network. It helps you forecast, allocate resources, and synchronize production with market demand. SNP also allows you to improve inventory control and demand shaping.

Conclusion

Demand planning is a critical aspect of every business. It involves estimating the market and then aligning supply with that order.

Hopefully, this post has given you a better understanding of the topic and how it works. We’ve also included some basic ideas about SAP software, SAP demand planning, and other related terms to continue your education on this vital topic.