Make-to-order is an approach of advanced manufacturing and supply chain management that entails the production of goods only in response to specific, customer-initiated orders, eliminating the need for large-scale inventory and pre-production.

This technique relies on precise demand forecasting, streamlined production processes, and agile manufacturing capabilities, all facilitated by cutting-edge technologies and data-driven decision-making.

By aligning production with real-time customer requests, this approach not only enhances operational efficiency, but also minimizes excess inventory, reduces carrying costs, and provides unparalleled flexibility to meet diverse customer needs with precision and responsiveness.

This can be contrasted with other methods like Make-To-Stock or Engineer-To-Order.

In this blog post, let’s look at what it entails, how it works, advantages and disadvantages of this technique.

What is Make-To-Order (MTO)?

It is also called a “Pull Supply Chain” strategy. This means that any item’s production, assembly, and delivery only happens when someone orders it. Making the item starts with a confirmed customer order, and the amount made depends on how many people buy it.

It is a manufacturing process that starts after receiving a customer’s order. Companies can use this process for products that are customized or unique.

This type of manufacturing helps to ensure that customers receive the exact product they want.

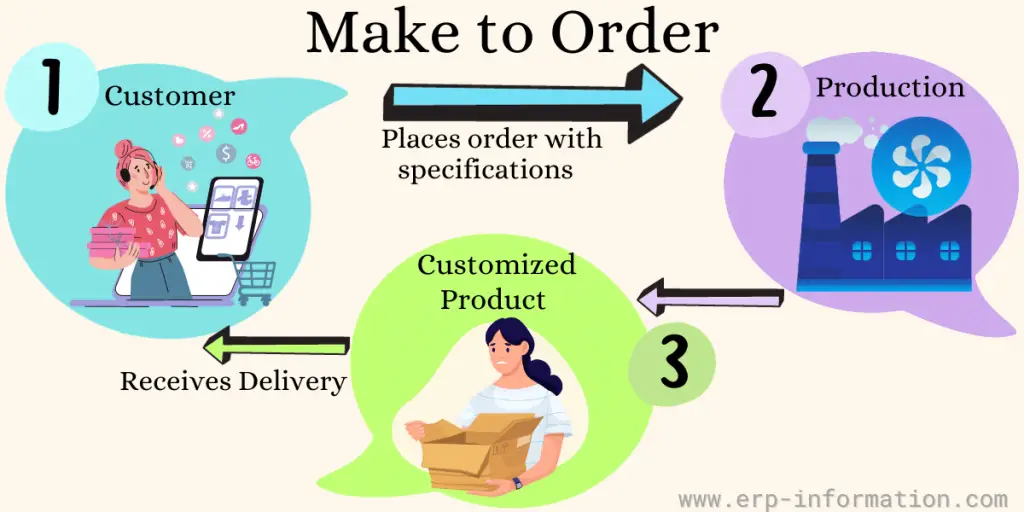

How does it work?

The process begins with the receipt of an order from a customer. Once the customer order is received, it is analyzed, and plans are made for producing the product.

The actual make to order production takes place according to these plans, with the finished goods being delivered to the customer once they are completed.

Make-to-order examples

The MTO approach is used by some industries, like

- Computer servers

- Airplanes

- Cars and bridge building

Let us see the examples in detail.

Computer servers

Using MTO in server manufacturing allows customers to select the exact components and features they need, resulting in servers that are tailored to their specific applications.

This approach has several benefits. It reduces inventory costs by only producing servers as needed. It minimizes waste by avoiding excess production. And it ensures that customers receive servers that perfectly match their computing needs, whether for data centers, cloud computing, or specialized applications.

Airplanes

Aircraft are highly complex and often require customization to meet the specific needs of airlines, defense organizations, or private buyers. MTO allows for the production of aircraft with tailored features, seating arrangements, avionics systems, and more, ensuring that each plane is designed to customer specifications.

This approach has a few advantages. It reduces the amount of excess inventory of pre-built aircraft. It is particularly useful when dealing with different types of aircraft configurations, like passenger, cargo, and military versions.

Cars

Some luxury car manufacturers in the automotive industry offer personalized options for their high-end vehicles. Customers have the opportunity to customize various aspects of their cars, such as color, interiors, technology features, and performance enhancements.

The manufacturer then assembles the vehicle according to the customers’ specifications to meet prerequisites to meet both aesthetics and performance. The focus is on meeting their specific requirements and creating a vehicle that is tailored to their preferences.

Bridge building

In bridge building, the Make-to-Order approach is not commonly used because bridges are usually big projects that follow standard building processes and use standard parts. However, in cases where custom or special bridges are required, MTO can be used.

So, if a bridge for pedestrians or cyclists needs to have specific designs, sizes, or architectural features, this method can be employed to meet those unique requirements. This approach allows flexibility in designing and constructing the bridge according to the project’s specific needs. It also reduces the need for pre-made parts.

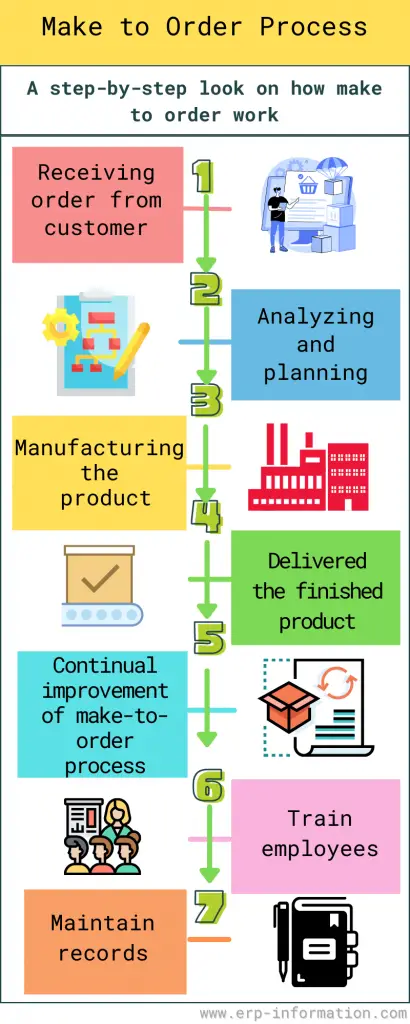

Make to order process flow

- Receiving customer order

- Analyzing and planning the manufacture of the product

- Manufacturing the product according to the plans

- Delivering the finished product to the customer

- Continual improvement of the process

- Training employees in these methods

- Maintaining records of all orders and products

Benefits

There are several key benefits to using it for manufacturing products,

- When customers get products that are designed just for them, they will be happier with what they receive.

- More flexibility in product design, as a company can make changes more easily and quickly than with other manufacturing methods.

- There are faster turnaround times, as there is no need to wait for the stock to become available before production begins.

- Reduced inventory costs, as products are only manufactured when customers have ordered them.

- Increased efficiency as the manufacturing process is tailored to meet each customer’s needs.

- Reduces waste and decreases overhead

Disadvantages of Make To Order Manufacturing

While there are many advantages to using it, there are also some potential drawbacks,

- Higher costs are due to the need for customized tooling and machinery and the demand for more skilled labor.

- There are long lead times, as products often take longer to manufacture than those made using other methods.

- Increased complexity in terms of planning and execution.

When is MTO the best option for manufacturing products?

It is a good choice for companies that want more flexibility in product design, faster turnaround times, and increased customer satisfaction.

This is more power full than the traditional production strategy to fulfill customer expectations. Customers will have a personalized shopping experience.

However, it is not always the best option, as it can be more expensive and have longer lead times than other manufacturing methods. Whether or not to use MTO depends on its specific needs and customers.

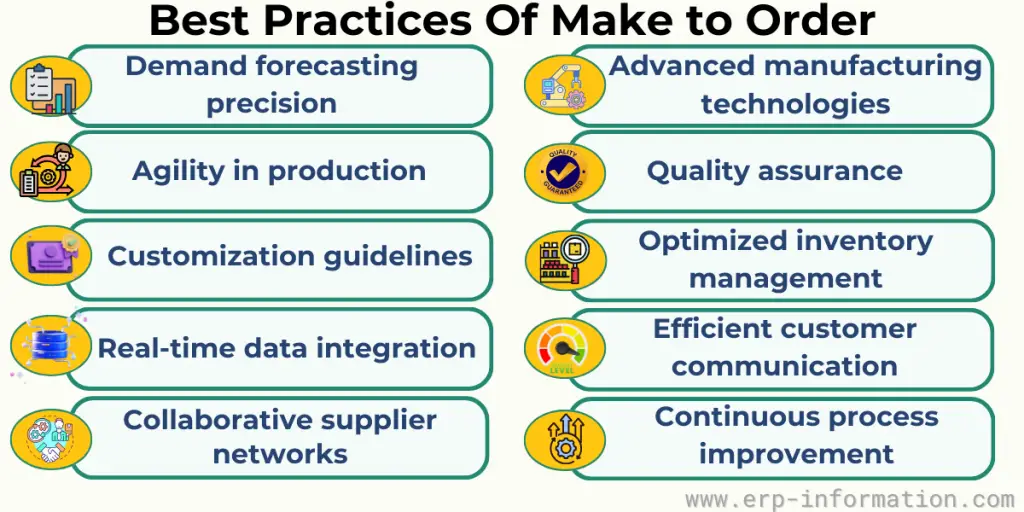

Best Practices

By following best practices, businesses can successfully adopt the make-to-order approach. This approach allows them to provide customized products to customers while maintaining efficiency and cost-effectiveness.

Additionally, it ensures that businesses uphold high standards of product excellence.

Here are some best practices.

Demand forecasting precision

Precise demand forecasting constitutes the bedrock of MTO. Utilize advanced analytical tools and historical data to predict customer orders, thereby optimizing production planning.

Agility in production

Develop production processes that are nimble and adaptable to swiftly accommodate varying customer demands. Lean manufacturing principles can serve as a valuable framework in this context.

Customization guidelines

Establish clear guidelines for customization. Define what can be customized and what should remain standardized to maintain cost-effectiveness.

Real-time data integration

Implement robust data integration systems that provide real-time information on order status, inventory levels, and production progress. This enables timely decision-making and order tracking.

Collaborative supplier networks

Forge strong partnerships with suppliers who can align with MTO requirements. Suppliers must have the ability to deliver components and materials promptly and on demand.

Advanced manufacturing technologies

Adopt the latest technologies, such as IoT, automation, and robotics, to improve manufacturing effectiveness. These technologies can aid in the smooth operation of the production process alongside the customization.

Quality assurance

Implement strict quality control measures to ensure that customized products meet or exceed customer expectations. Quality assurance should be followed in every stage of production.

Optimized inventory management

It is important to maintain a strategic inventory buffer for frequently ordered components and materials. Also, the inventory for commodities with less demand must be minimized. This step helps maintain the equilibrium and balances responsiveness and cost control.

Efficient customer communication

Efficient communication channels with customers must be set up. This helps understand their customization requirements. It is very important to capture and pass on accurate order information to the production floor.

Continuous process improvement

Regularly evaluate and optimize MTO processes. To improve, it is essential to ask for feedback from both customers and employees. Valuable insights gained from this feedback can be used to implement enhancements.

Make-to-Order vs Make to Stock

Both MTO and MTS have their advantages and disadvantages, and the choice between the two depends on some factors. Some companies may even use a combination of both approaches to balance inventory levels and respond to different customer requirements.

Here we discuss a few of their differences:

| MTO Approach | MTS Approach |

| MTO manufacturing is initiated by a specific customer order, ensuring that items are produced or customized only after receiving an order confirmation. | MTS manufacturing involves producing goods in advance based on forecasts, historical sales data, or predetermined stocking levels. |

| The customer can specify precisely what they want, down to the individual product and color. | The customer is limited to pre-determined choices. |

| This approach tailors each product specifically for the customer who orders it. | It use a more “one size fits all” approach. |

| It maintains lower inventory levels since products are made on-demand that helps to reduce carrying costs and minimizes the risk of excess inventory. | It maintains higher inventory levels to ensure immediate availability for delivery, which can lead to higher holding costs. |

| It often has longer lead times as production begins after an order is received, requiring customers to wait for the manufacturing process to be completed. | It usually has shorter lead times as products are already in stock and ready for immediate shipment. |

| It is well-suited for highly customized or personalized products, providing flexibility in meeting specific customer requirements. | It is suitable for standardized products with minimal or no customization, where items are produced in large quantities to meet general market demand. |

| It carries a lower risk of overproduction since items are made in response to confirmed orders. | It carries a higher risk of overproduction if demand does not align with forecasts, potentially resulting in excess inventory. |

| It allows for quick responsiveness to changing market demands or customer preferences since products are produced as needed. | It may experience delays in responding to market changes due to the time required to adjust production levels. |

| It can be more cost-effective in terms of inventory management, although it may have higher production costs due to smaller batch sizes. | It may have higher carrying costs due to larger inventories, but it can benefit from economies of scale in production, resulting in lower unit costs. |

| It supports a wide range of product varieties and customizations to meet individual customer needs. | It focuses on a more limited set of standardized products with fewer variations. |

Current Trends In Make-TO-Order Manufacturing

The make-to-order manufacturing industry is experiencing several significant trends that are shaping its future.

One main trend is the digital transformation of MTO processes, driven by the integration of Internet of Things (IoT) sensors, artificial intelligence (AI), and data analytics. This integration allows for real-time monitoring and data-driven decision-making.

Another trend is the growing demand for mass customization. Customers increasingly want personalized products, which has led MTO manufacturers to develop efficient techniques for mass customization at scale.

Sustainability and eco-friendly practices have become a focal point for the MTO industry. Companies are adopting eco-friendly materials and implementing energy-efficient processes to align with sustainability goals.

Collaborative manufacturing is also on the rise in MTO. The use of collaborative robotics and automation allows for improved productivity through human-machine collaboration.

3D printing has gained popularity in the MTO sector. It enables rapid prototyping and the production of customized components with reduced lead times.

The lessons learned from the COVID-19 pandemic have highlighted the importance of supply chain resilience. MTO manufacturers are diversifying their supply chains, implementing risk mitigation strategies, and leveraging digital tools to enhance visibility and adaptability.

To meet the demands of e-commerce, on-demand manufacturing has become a prominent trend in MTO. Manufacturers strategically locate their facilities closer to customers to minimize lead times and shipping costs.

Augmented Reality (AR) and Virtual Reality (VR) technologies are being utilized in MTO to enhance design, customer interaction, and training processes. Blockchain technology is also being employed for traceability in the MTO supply chain, ensuring transparency and authenticity.

Advancements in materials have expanded the possibilities for MTO manufacturers, offering stronger, more durable, and versatile options.

Smart factories are emerging in the MTO industry, with connected machinery and systems enabling real-time data control for more efficient production.

FAQs

What are Make to Order product examples?

Some examples are customized sneakers, made-to-order furniture, made-to-order clothing, and special orders for food items such as personalized pizzas or burgers.

With these products, the customer can select different colors, sizes, and designs made specifically for them.

This type of manufacturing allows for a high level of customization and personalization that often isn’t possible with mass-produced items.

Many companies now offer online platforms that allow customers to fully customize the products they order, down to the most minute detail.

This trend towards increased customization is likely here to stay as consumers become savvier and savvier about the benefits of having precisely what they want – and nothing more.

How does Make to Order impact inventory?

Products made with a make-to-order process tend to have a lower inventory turnover rate.

This is because the products are made specifically for consumer demand, so there is no need to keep large quantities of the product on hand. It will increase production efficiency.

This can be beneficial for businesses that want to avoid dealing with excess inventory, but it can also lead to longer wait times for customers.

Is it better for high-volume or low-volume production?

Generally speaking, Make to Order production is more beneficial for low-volume production companies. This is because setting up the necessary infrastructure for high-volume production can be difficult and expensive.

Also, make-to-stock production often results in excess inventory, which can tie up a company’s financial resources.

However, make-to-order products can be less efficient than make-to-stock production, and it may not be possible to meet customer demand if orders are received too late in the production process.

As a result, companies must weigh the pros and cons of each type of production before deciding which one is best for their business.

What is make-to-order in SAP?

SAP is used when products are not in stock and need to be made for a customer.

This is done using the MRP ( Materials Requirement Planning) function in SAP. MTO is beneficial because it allows businesses to create products tailored to customer needs, increasing sales and customer satisfaction.

In addition, it can help businesses to avoid the high costs associated with inventory management and storage.

However, it can also be complex and time-consuming, so it is essential to carefully consider the best option for your business before implementing it.

Conclusion

Make-to-Order is a manufacturing process where production starts only after receiving an order from a customer. This allows for more customization and variety since the products are not produced in bulk ahead of time.

It can benefit customers and businesses because it results in shorter lead times, less waste, and lower inventory costs. Hoping this reading was helpful for you!