Assemble-to-Order (ATO) is a manufacturing strategy that allows users to combine a limited number of subassemblies into many possible finished items.

This strategy allows various customization options, shorter lead times, and low inventory risk.

This blog post will discuss what Assemble-to-Order is, how it works, some of the benefits you can expect from using it in your business, and its disadvantages.

What is Assemble-to-Order?

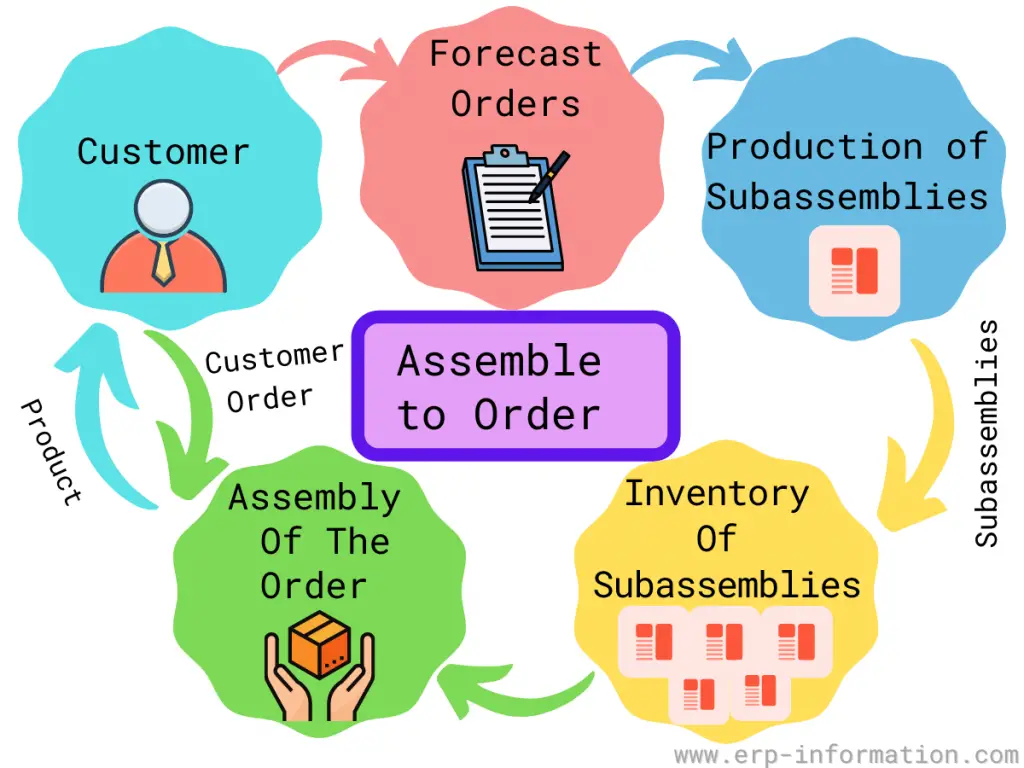

Assemble-to-Order is a manufacturing strategy that combines a few different parts to make many other things. This way, people can quickly get what they want, and it’s easier to customize things. It is the hybrid version of the make-to-stock and make-to-order strategy.

Here, the manufacturer produces basic parts before the order but will not be assembled. However, once they receive the order from the customer, they assemble the parts easily as per the customer’s requirements, and the ready product will reach the customer quickly.

In this way, it allows businesses to produce customized products to the individual customer’s needs quickly.

Here is an example for a better understanding of the ATO concept.

Assemble-To-Order Examples

Example 1

Imagine a scenario where you want a brand-new laptop tailored to your specific needs. In this example, you are the customer, and the manufacturer offers an Assemble-to-Order strategy for creating customized laptops.

Before you even place an order, the manufacturer produces various basic components for the laptop, such as the motherboard, screen, keyboard, and battery. These components are standard and widely used in their laptop models.

You, as the customer, visit the manufacturer’s website or store to order your laptop. You’re not just choosing from a list of pre-made laptops; instead, you get to customize it.

You start by selecting the features you want. You pick the processor, the amount of RAM, the storage size, and even the color of the laptop.

Once you’ve made your selections and placed your order, the manufacturer doesn’t need to start from scratch. They already have the essential components ready.

It’s time to assemble your laptop according to your specifications. They attach the motherboard to the screen, insert the RAM, install the chosen processor, and assemble all the parts together. This is how Assemble to order works.

Example 2

Assume that you are the mobile handset manufacturer. You can have all the required handset parts, like battery, circuit board, speaker, microphone, and LCD, in stock.

You may need all these components for all models. When you get customer orders, you can easily assemble and customize the final product per customer requirements.

What are the Advantages of Assemble to Order?

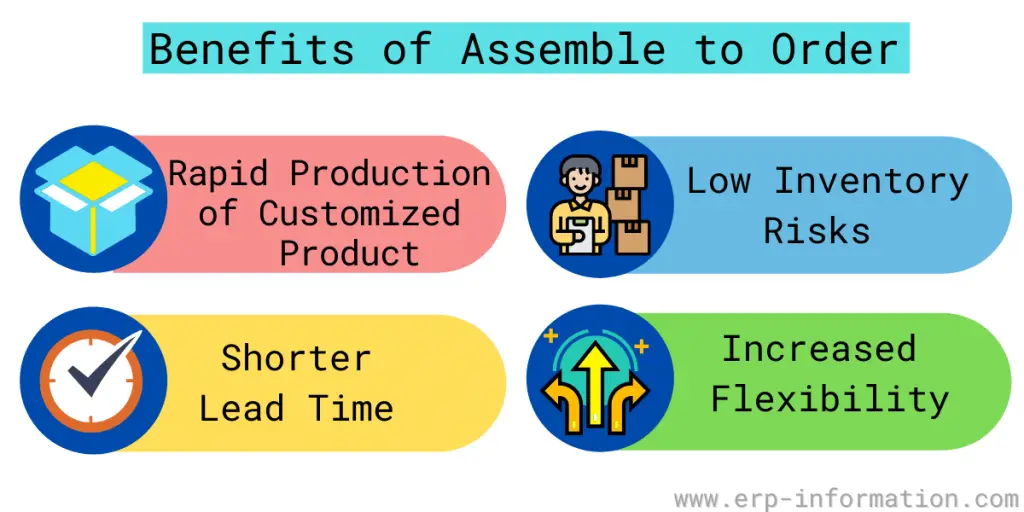

There are many benefits to using Assemble-to-Order in your business. Some of the key advantages include the following:

Rapid production of customized products

It allows you to combine a limited number of subassemblies into many possible finished items. This means that you can quickly produce products tailored to the customer’s specific needs.

Shorter lead times

It also helps shorten lead times because it eliminates long production runs. In addition, assembling products on demand means that you can create custom orders with little or no wait time.

Low inventory risk

It also helps reduce inventory risk because it allows businesses to produce only when needed. This prevents costly overstocking and minimizes the amount of inventory held in reserve.

Increased flexibility and variety for customers

And ATO gives customers more flexibility and variety because it allows them to choose from a broader range of customized products. This can be a significant advantage in fierce competition, and customers are looking for unique options.

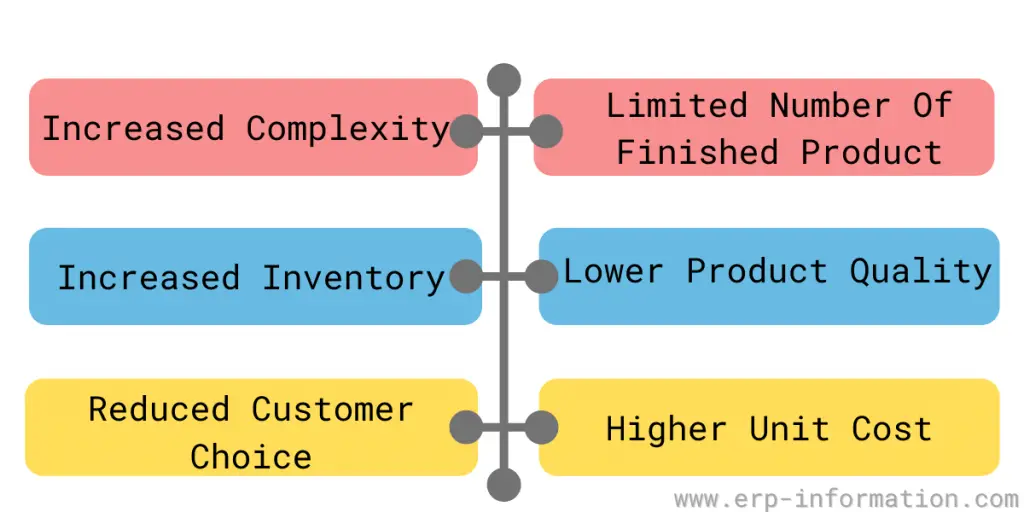

Disadvantages of using ATO

There are six main disadvantages of using Assemble-to-Order:

- Increased complexity and setup time

- A limited number of possible finished items

- Increased inventory

- Lower product quality

- Reduced customer choice

- Higher per-unit cost

How to get started with Assemble-to-Order strategy?

If you’re looking to get started with Assemble-to-Order in your business, here are the steps to help you get started:

- First, decide what products you want to offer Assemble-to-Order.

- Next, break those products down into a limited number of standardized subassemblies.

- Combine the subassemblies in a variety of ways to create finished products.

- As customers order different items, mix and match the subassemblies to create the desired outcome.

- Ensure you have the necessary equipment and personnel to support Assemble-to-Order production.

- Train your staff on the new production process.

- Finally, evaluate and optimize Assemble-to-Order to ensure that it meets your specific needs.

Ten questions to ask before implementing the Assemble-to-Order strategy

- What are the products that you want to offer?

- What are the subassemblies for those products?

- How many variations of each product can be created using the subassemblies?

- What are the lead times for production?

- How much inventory needs to be stocked for production?

- What is the cost of implementing it in your business?

- What are the benefits?

- How will it impact your customer’s experience?

- What skills and resources do you need to support this kind of production?

- Are there any potential risks associated with it?

If you answered “no” to any of these questions, it might be wise to reconsider implementing Assemble-to-order in your business. However, if you can answer affirmatively to all of them, then Assemble To Order may be an excellent fit for your company!

FAQs

What companies use assemble-to-order?

Some companies that use it are Dell, Toyota, and Airbus.

What does it mean to assemble products?

Assembling products means putting together the individual parts or components of a product to create the final item. This can be done in-house or by contract manufacturers. Assembling products can involve many tasks, from simple operations to more complex welding, fabricating, and molding.

What are the common components of Assemble-to-order?

Semi-Finished Components: These are components that are halfway to completion, allowing for easy customization and assembly to fulfill unique customer needs.

Subparts and Subassemblies: These are like the building blocks of the final product, comprising smaller parts and pre-assembled components that can be pieced together to create the finished item.

Intermediate and Fabricated Components: These are the parts that may need some extra work or fabrication before they’re ready to become part of the end product.

Packaging Materials: These materials are essential for wrapping and safeguarding the product during shipment, ensuring it reaches the customer in good condition.

How ‘Make To Order’ is different from Assemble-To-Order’?

Make-to-order means creating products entirely from scratch based on what each customer wants. It’s like baking a cake from scratch with unique ingredients and decorations for each order.

Assemble-to-order involves assembling products using pre-made sub-assemblies and components. It’s more like making a sandwich from ingredients you already have – you customize it with the ingredients on hand, but they’re not made from scratch for each order.

Conclusion

ATO is a manufacturing strategy that allows users to combine a limited number of sub-assemblies into many possible finished items. This strategy enables a wide variety of customization options, shorter lead times, and low inventory risk.

It can be used in various industries, including automotive, aerospace, medical device, and consumer goods.

Using ATO as your manufacturing strategy can quickly produce customized products with short lead times and low inventory risk. Thanks for reading!