Most businesses don’t have the time or resources to develop a sophisticated production strategy. However, without a well-developed production strategy, a business is at risk of running out of products and being unable to meet customer demands.

The chase production strategy is one of three primary types of aggregate planning techniques; the other two are the Level production strategy and the third, hybrid strategy.

Chase Production Strategy is a simple but effective way to plan your production and avoid stock-outs.

This post will cover what you need to know about the Chase Production Strategy, including how to implement it and the advantages and disadvantages.

Evaluate the Chase Production Strategy using our Online Chase Production Strategy Calculator

What is the Chase Production Strategy?

The chase production strategy is a production strategy in which production is adjusted to meet the fluctuations in customer demand. This contrasts with a level production strategy, in which production is constant regardless of demand.

Chase production strategy is a way to plan your production and avoid stock-outs. The basic idea is to keep track of customer demand and produce enough products to meet demand while leaving room for inventory. It is suitable for seasonal items.

This strategy is also called the “Demand matching” strategy because, in this production strategy, you will vary production to meet customer demand.

When to Use the Chase Production Strategy?

It is best suited for businesses that experience significant fluctuations in demand. This can be due to seasonal factors, such as a business that sells ice cream cones in the summer and hot chocolate in the winter.

It can also be due to other factors, such as a business that produces custom products or operates in a highly competitive market.

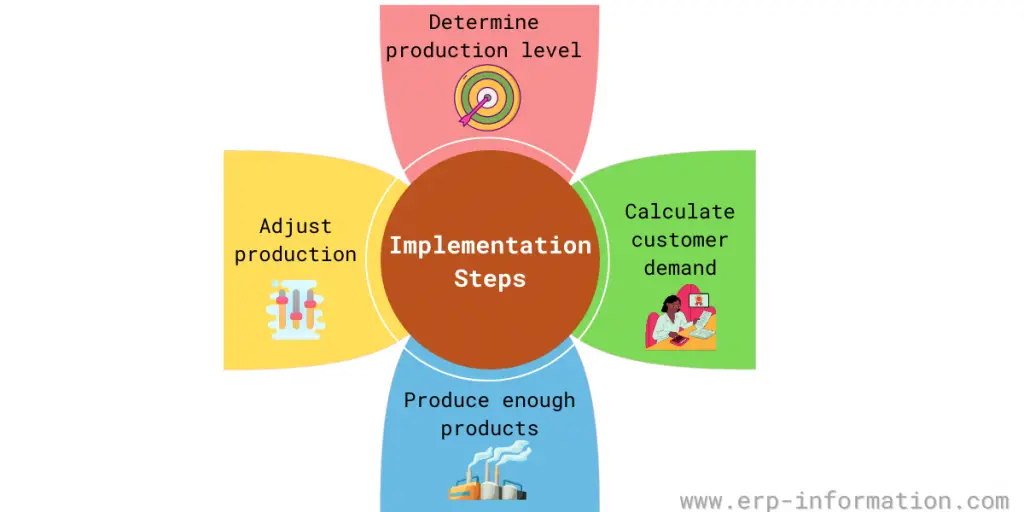

How to Implement Chase Production Strategy?

There are a few simple steps to implementing the Chase Production Strategy:

Determine your desired production level

You must decide how much product you want to produce in advance. This number should be based on your projected sales and the amount of product you need to keep in stock.

Calculate customer demand

Once your desired production level is determined, you can calculate the demand for your product. Please track the amount of product and time of purchase of your customers buy. This information will help you plan your production in advance.

Produce enough products to meet demand

Produce sufficient products to meet customer demand while leaving room for inventory.

Adjust production as needed

Match your production to customer demand. If demand increases, increase production. If demand decreases, decrease production.

Chase Strategy Formula :

1. Net Requirements

Net Requirements = Demand−Beginning Inventory

This formula calculates the total units that need to be produced for the month after accounting for the inventory already available at the beginning of the month.

Evaluate Net Requirements using our online Net requirements calculator

2. How Many Workers

Number of Workers = Net Requirements X Units per Worker

This formula determines how many workers are needed to meet the net requirements, assuming each worker can produce a certain number of units per month.

3. Regular Production

Regular Production = Number of Workers×Units per Worker

This calculates the total production based on the number of workers and how many units each worker can produce.

4. Ending inventory

Ending Inventory = Beginning Inventory+Production−Demand

This formula calculates the inventory level at the end of the month. It takes the starting inventory, adds what was produced during the month, and subtracts what was sold (demand).

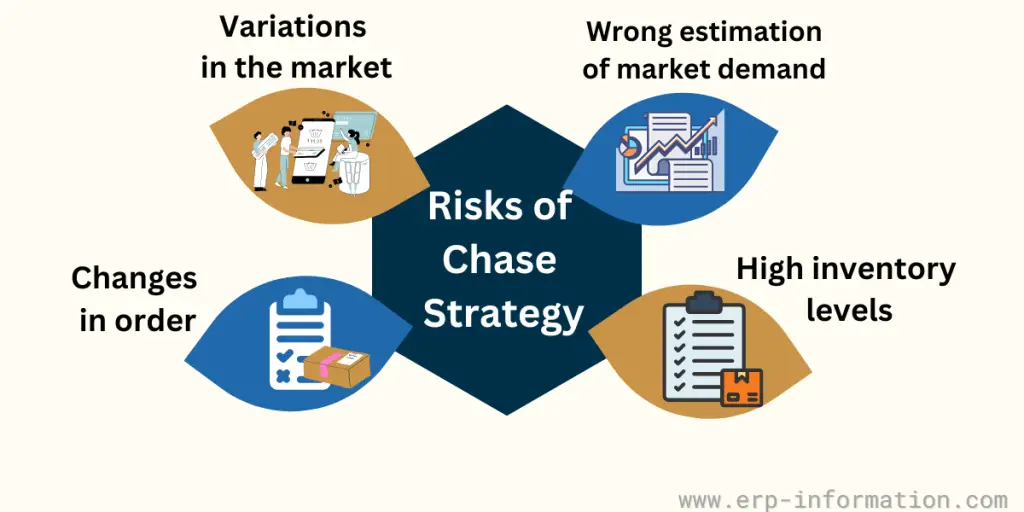

Risks of Chase Strategy

There are a few risks associated with using the chase strategy:

- Variations in the market – If there is a sudden change in the market, your production levels may not be able to meet customer demand.

- Changes in order – If customers change their orders at the last minute, your production levels may not be able to meet customer demand.

- High inventory levels – If you produce too many products, you will have high inventory levels and excess products that you may be unable to sell.

- Wrong estimation of market demand – If you underestimate the market demand, you may not be able to meet customer demand. If you overestimate the market demand, you may have excess inventory you cannot sell.

Chase Production Strategy Example

Let’s take an example of a company producing caps using the chase production strategy.

The company sets a goal to produce 1000 caps per month. At first, they started calculating customer demand per month. They track consistent orders from previous months and calculate the average to determine customer demand. Based on this information, they plan to produce 250 caps per week. They made the necessary arrangements for the inventory.

Next month, they will adjust production as needed to match customer demand. If demand increases, they increase production. If demand decreases, they decrease production. This way, they can avoid stock-outs and always have enough caps to meet customer demand.

Advantages of Chase Production Strategy

Helps you avoid stock-outs

By keeping track of customer demand and producing enough products to meet demand, you can avoid running out of products and frustrating your customers.

Meets customer demand

The strategy meets customer demand by producing the right amount of products to match demand.

Flexible

The Chase Production Strategy can be adjusted to meet changing customer demand. This allows businesses to respond quickly to changes in the market and ensure that they are always meeting customer needs.

Prevents excess inventory

By producing only what is needed to meet customer demand, businesses can avoid having excess inventory that they cannot sell. This helps to keep costs down and prevents waste.

Disadvantages of Chase Strategy

- Increased inventory levels due to longer production runs

- Lower product quality as a result of increased batch sizes

- Longer lead times from order to delivery

- Difficulty in responding to changing customer demand

- Higher production costs per unit due to economies of scale not being realized

Chase Production Strategy VS Level Production Strategy

| Chase production strategy | Level production strategy |

| Under the chase production strategy, production is adjusted to match fluctuations in customer demand. This means that businesses may need to hire and fire workers more frequently, and they may need to purchase more expensive equipment that can be easily scaled up or down. | Under the level production strategy, production is kept constant regardless of demand. This means businesses will produce the same amount of products each month, even if demand fluctuates. |

| Reduces the inventory cost and improves the customer satisfaction. | This can lead to high inventory costs and stock outs if demand is higher than expected. |

| It is challenging to implement and more expensive. | It is easier to production implement and less expensive than chase production. |

Use Cases/Real World Example

Chipotle Mexican Grill – A Restaurant Company

Let us take the example of a restaurant company Chipotle. Chipotle’s approach showcases the practical application of the chase production strategy in the restaurant industry. Their approach aligns with the principles of adjusting production to meet fluctuating customer demands.

1. Demand Matching and Agile Production

Chipotle incorporated the chase production strategy by tailoring production to customer demand. During peak hours, they ensure a ready supply of food by adjusting the pace of their assembly line to meet the surge in orders. This agility allows them to keep up with high demand while avoiding stockouts.

2. Flexible Workforce and Training

Their employment model of hourly-paid, easily trained staff enables swift adjustments in workforce size based on customer demand. This adaptability in staffing facilitates a responsive production approach aligned with varying customer demands throughout the day.

3. Customization and Efficient Production

The assembly-line setup allows for customizations based on customer preferences. This efficient production process ensures orders are fulfilled rapidly, maintaining quality and timeliness. It is a key aspect of the chase production strategy.

4. Optimizing Supply and Revenue Potential

Chipotle’s ability to adjust its supply, like offering extra meat for a slightly increased price, reflects the chase strategy’s essence.

By recognizing high-demand periods and offering increased quantities for a slightly higher price, they leverage the principle of supply and demand, potentially maximizing revenue without compromising customer satisfaction.

5. Balancing Supply and Price Sensitivity

They understand that customers often pay more for increased supply or additional value. Chipotle’s willingness to adjust supply quantities and slightly modify prices reflects a strategic balance between meeting demand and maximizing revenue.

FAQs

What is a Hybrid production Strategy?

The Hybrid production strategy maintains a consistent production rate up to a certain point and uses variable workforce levels or outsourcing to accommodate fluctuations in demand beyond that base production rate.

This strategy is particularly useful in environments where demand variability is moderate and where both holding costs and costs of changing production rates are significant.

Conclusion

Chase production strategy can be a good tool for businesses seeking to align their production processes with fluctuating market demands.

By meticulously adjusting workforce levels and production rates, companies can effectively manage their inventory levels, reducing costs associated with excess stock and storage.