Capacity Requirements Planning, or CRP for short, is a process businesses use to determine their future resource needs.

In other words, it helps business owners figure out how much space, equipment, and human resources they will need to reach their goals.

Without proper CRP planning, your business may struggle to keep up with demand or face unexpected expenses down the road.

This blog post will discuss the basics of Capacity Requirements Planning including its definition, affecting factors, strategies, advantages, and disadvantages. It also explores how you can use it to determine your business’s needs.

Definition

Capacity requirements planning (CRP) is the process of establishing, measuring, and adjusting limits or levels of capacity.

The term CRP in this context refers to determining the labor and machine resources required to accomplish production tasks.

Capacity requirements planning is one of the management tools. It helps the company use its resources efficiently by making its production process accurate.

It determines the capability of the production goal of the company. The company can determine how many products it can make and meet production objectives through this process.

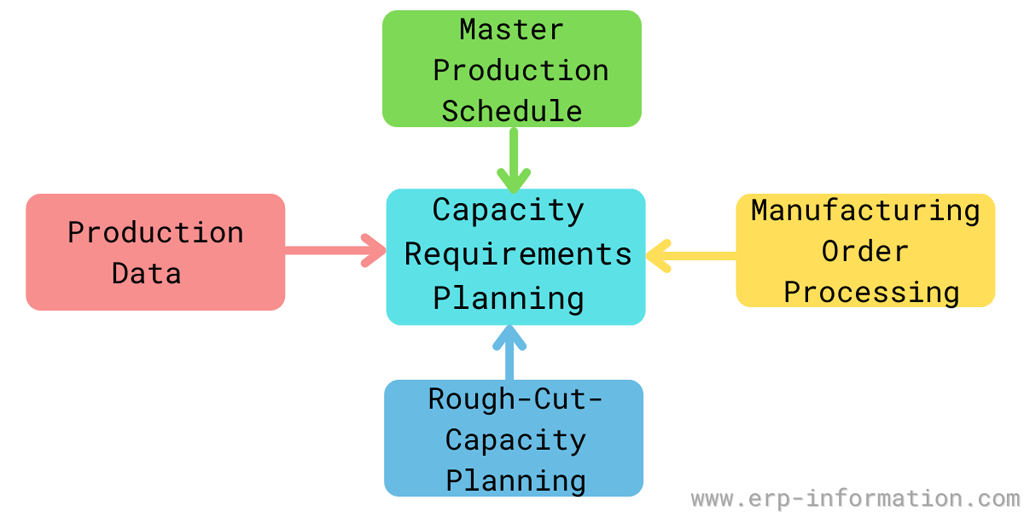

You can get all the above data by referring work center file, open order file, material requirement plan, and routing file.

How do you plan capacity requirements?

It is an essential aspect of the company. A company develops its capacity requirement plan based on some factors.

With the help of the following steps, you can easily plan the capacity requirements.

Discover the requirements at the work level

To determine the work level capacity requirements, you need to arrange the workloads based on the type of work, the process of work, and the person who does the job.

Once this workload arrangement is completed, define a satisfactory service for every work, determine the resources required to attain that work, and calculate the amount of work done.

After that, set a service level agreement (SLA) between the vendor and the customer.

Study the present capacity

Before planning the capacity requirements, analyzing the present capacity is a crucial aspect.

First, you must match the quantification of items referred to in the service level agreement with their goals.

Then find out the usage of resources. Finally, check out which workload is the leading consumer of each resource.

Define a plan for the future

Estimate the amount of work over certain quarters and determine the system for satisfying service levels.

Once you plan the capacity requirements, re-evaluation is also more critical. That is because capacity requirements planning depends on the type of business and industry.

How to re-evaluate capacity requirements planning?

Following are a few tips to re-evaluate CRP.

- Study the latest inventory and sales records to find the number of selling products or services.

- Find out whether the demand is increasing or decreasing.

- Study the production records to find the number of products the company manufactures.

- Suppose the production is sufficient to meet the future demand without making changes. However, if this is not enough, the company has to increase capacity requirements and the production level by hiring more employees, upgrading equipment, and upgrading technologies.

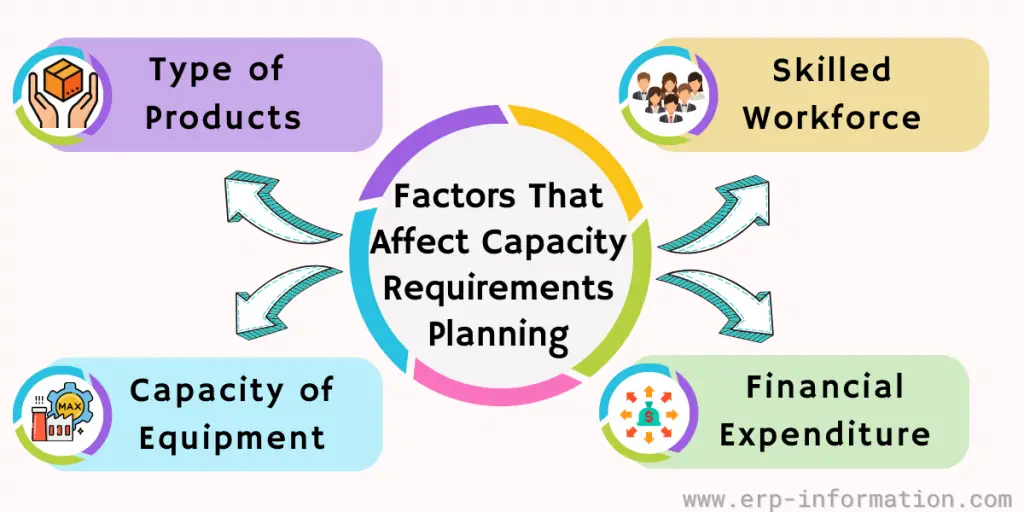

Factors that affect the capacity requirements planning

Some of the factors affect capacity planning. They are

- Type of products: Products with complexity require more time to produce, lead to delays in the production process, and require more skilled employees and the most efficient equipment. Simple products need less time. Hence it can be produced in large volumes within a short period.

- Financial expenditure: The company must have the ability to invest in machinery or workforce.

- Availability of skilled workforce: If the company has the same qualified or no skilled employees, it affects the output product’s capacity.

- The capacity of the equipment: Equipment in good condition helps speed up the production process.

Capacity requirements planning advantages

- CRP plays an essential role in the success of a company.

- It gives a clear picture of the ability of the company to meet its customer demand.

- It helps determine how much that company must invest in its employees, equipment, and materials.

- It helps to find the company’s place in the market.

- It helps to do on-time delivery of the products or services.

Capacity requirements planning disadvantages

Consumes more time

It consumes more time to do the planning. It is easier and less time-consuming to assign the work to an employee when the project comes than to schedule it.

But by considering the size of your company, you need to execute CRP. Nowadays, you can speed up capacity requirements planning with the help of planning tools.

Hard to maintain discipline

Maintaining discipline throughout the project in the organization is one of the disadvantages.

You need to schedule the capacity requirements in the exact structure, and managers or supervisors should consider it their essential task. Otherwise, there will be a chance of breaking the schedule at the employee level.

How is CRP used in manufacturing?

Capacity requirements planning in manufacturing is a critical process that helps ensure everything runs smoothly. It involves figuring out how much a factory can produce and when to make sure it meets demand without any hiccups.

working of CRP in manufacturing is as follows.

Understanding Demand: First, the manufacturers need to know how many products people want to buy.

Checking Resources: Manufacturers check the resources that they have such as machines, materials, and people.

Scheduling Production: Once they know what’s needed and what they have, they create a plan. This plan outlines when each product will be made, making sure machines and workers are used efficiently.

Adjusting for Changes: Things might change, just like unexpected guests showing up. Manufacturers regularly check if they need to tweak their plans based on changes in demand or unforeseen issues.

Avoiding Bottlenecks: In manufacturing, they identify potential bottlenecks (places where things might slow down) and plan to prevent them.

In a nutshell, capacity requirements planning is like planning a big meal. It’s about making sure you have the right ingredients, know when to cook each dish, and can handle any surprises that come up—ensuring a smooth and efficient production process.

Types of capacity requirements planning strategies

The capacity requirement strategy helps manufacturers to determine the number of raw materials, machines, and labor resources required for some time to meet customer demand for products or services.

If there is a lack of capacity planning, it is difficult to meet customers’ demands, leading to losing the customer.

1. Lead strategy

This method is an aggressive approach. In this method, the manufacturer invests to increase its resource capacity before increasing actual demand.

This strategy allows the manufacturer to get market share opposite to his competitors. The con of this method is that there will be a chance of excess inventories when the actual demand is lesser than the predetermined demand.

2. Lag strategy

This strategy is directly opposite to the lead strategy. In this approach, the manufacturer only adds the required capacity when the available capacity crosses its limits.

The manufacturer waits to enhance the capacity till the increase in actual demand. In this method, there is no risk of storing extra inventories.

3. Match strategy

It is the in-between strategy of lead and lag strategies. In this method, the manufacturer gradually adjusts or boosts the capacity according to the market condition.

4. Dynamic strategy

This is the safest type of approach. In this method, the manufacturer adds the capacity before it is required by analyzing the sales forecast and actual demand. Hence this strategy is accurate and less risky.

Capacity requirements planning software

Capacity requirement planning software is a tool that helps the manufacturer to determine the actual production capacity and adjust the available capacity to meet the demands.

It is beneficial to the company in many ways.

- It clearly shows short-term and long-term operational bottlenecks and possible alternatives.

- It provides real-time data and manual options that help the manufacturer fulfill customer orders.

- It continuously optimizes production planning.

FAQs

What are the inputs required for Capacity Requirement Planning?

The inputs required for capacity requirement planning are the capacities of each work center, open shop order, lead times, routings, and planned order releases.

What is the capacity requirements planning strategy?

Capacity requirements planning strategy is the process used to find and add the required capacity and the available resources to meet customer demand.

What are the industries that use capacity requirements planning?

The industries that use capacity requirements planning are

– Food and Beverage

– Automotive

– Medical devices and Pharmaceuticals

– Consumer products

– Electronics and Tech devices

– Industrial manufacturing

Conclusion

Capacity Requirements Planning is a business process that identifies the needs of an organization in terms of production capacity and then plans how to meet those requirements. Capacity can include labor, equipment, materials, or even space.

This article will teach how CRP helps businesses identify their future needs and possible risks before it’s too late!