Keeping track of all the tasks that need to be completed can often feel like a daunting challenge, especially when you’re managing multiple projects simultaneously.

It’s hard to stay organized and on top of things, but it can feel impossible when you have no idea where to start.

Work Center was created with the modern worker in mind. It provides a simple and efficient way for you to schedule, calculate, and structure your workday to get ahead.

In this blog post, we will discuss what a Work Center is What are the scheduling and calculation methods? And what is its structure? We’ll answer all of these questions and more! Stay tuned!

What is a work center?

The work center is a physical location where specific tasks or activities are carried out in business. It is a physical or logical production area that schedules and routes production operations.

For example, a work center for producing printed materials may have different areas for preparing the paper, cutting type, running press sheets, etc. It can also help improve efficiency by ensuring employees have easy access to the tools and equipment to do their jobs. By creating well-defined work centers, businesses can improve productivity and optimize resources.

It is usually defined as being either labor or machine-constrained. While it may contain multiple machines or personnel, they are considered identical in processing products assigned to that center.

It may perform multiple operations, but capacity requirements are usually tracked only at the total work center level.

Its definitions can be flexible based on process, reporting capabilities, and organization requirements.

What is the function of a work center in production?

A work center is a place where production takes place. It consists of “equipment, people, and material” required to produce goods or services. The placement of machinery can affect efficiency, resulting in the difference between an assembly line and the batch production process.

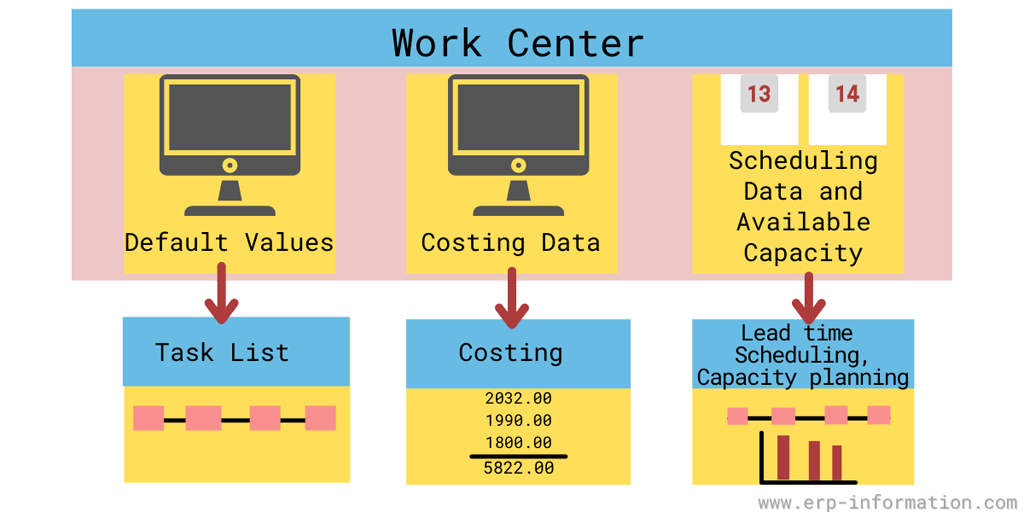

Uses of data in the work center

Data here is used for

- Scheduling: Formulas entered here help to calculate the duration of an operation.

- Costing: The formulas here allow you to calculate an operation’s costs.

- Capacity planning: Formulas for calculating capacity requirements and capacity availability are stored here.

Work center scheduling

Workcenter scheduling is a technique used in lean manufacturing to optimize resources and improve flow.

It involves creating a schedule for each center in the production process that shows what work will be done at each center and when it will be done.

That allows the factory to plan production so that suitable types of work are done at the right time, and resources are used efficiently.

The following are the main goals of this scheduling.

- Decreasing lead time

- Decreasing set-up time

- Increasing utilization of machine and labor

- Decreasing work in process inventory

- Meeting due dates

Work center in SAP

The plant maintenance and control module is crucial for SAP production planning (SAP PP). It allows for optimized routes, reduced waiting time at job sites with its integrated human resource management system (HRMS) features like payrolls or employee benefits administration, and increased reporting accuracy.

What is the work center in SAP PP?

It is a logical grouping of activities that share resources or are done in parallel. For example, you might create a work center for processing customer orders and another for packing the orders.

You would then assign the appropriate resources to each work center, such as machines and employees. That would allow you to optimize the use of your resources and improve throughput.

It can be as simple as a single workstation or as complex as an entire factory. In most cases, each will have one or more associated resources (e.g., machines, tools, workers) necessary for performing the work assigned to that center.

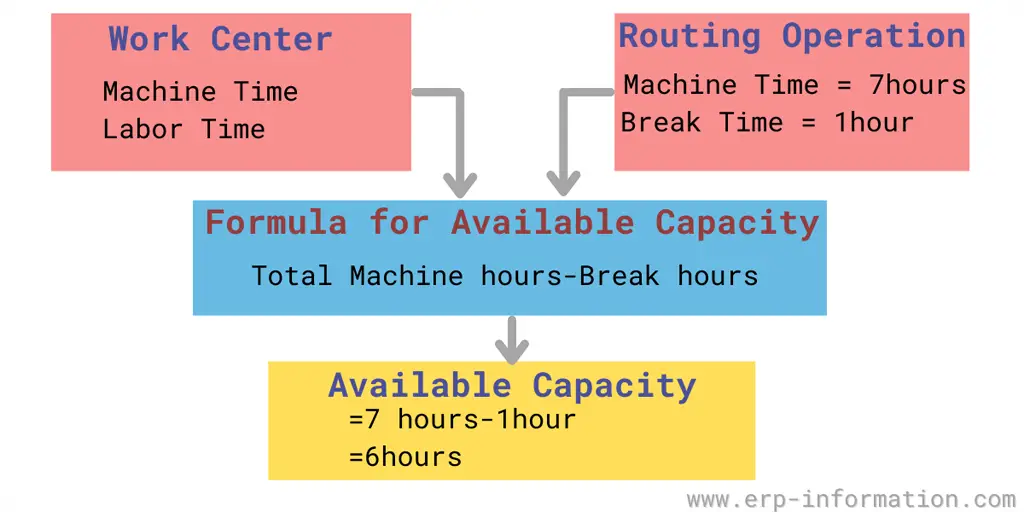

Capacity calculation in SAP

- Available capacity: SAP work center capacity indicates machine or labor available hours. Here break hours are not included. For example, a machine is available for production in the production plant from 10 am to 5 pm, and the break time is 1 hour.

Then the available capacity is = Total available hours – break hours

Available capacity = 7 hrs – 1 hr

Available capacity = 6 hrs

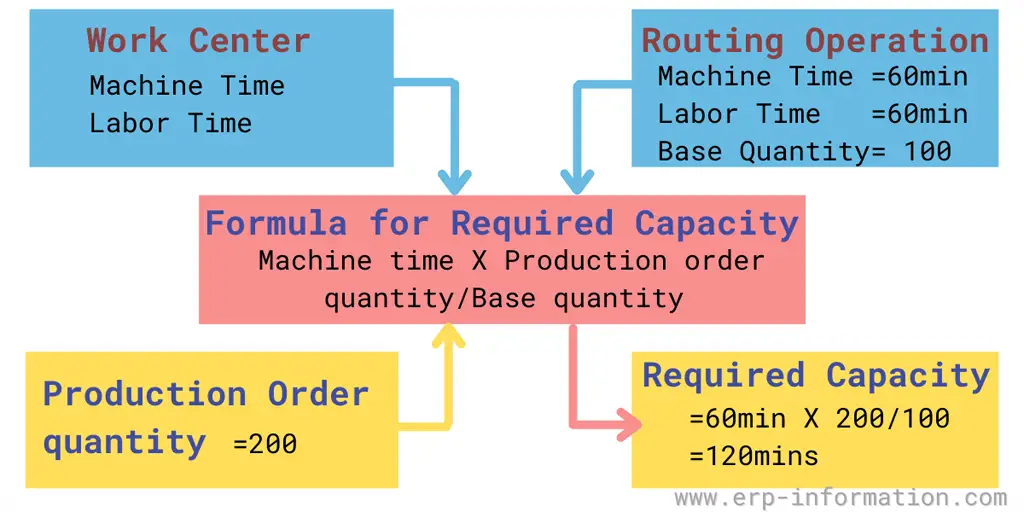

- Required capacity: In the SAP work center, required capacity means the time required to produce a specified quantity of product. To calculate the required capacity, SAP considers operation time and capacity formula.

For example, in a factory, the usage of a machine maintains things like labor time, machine time, and set-up time. Let us assume the routing time and quantity.

- Labor time 60 mins

- Machine time = 60 mins

- The machine set up time = 30 mins

- Base Quantity = 100

- Production order quantity = 200

Now the capacity calculation for that machine is

Required capacity = machine time X production order quantity/base quantity

Required capacity = 60 mins X 200/100

Required capacity = 60 mins X 2

Required capacity = 120 mins.

Evaluate Production Capacity using our Online Production Capacity Calculator

Work center structure

It contains mainly three levels.

- Department

- Planning area

- Work center

It can be internal or external. An example of a shallow work center is the contractor. In the olden days,’ the work center consisted of electrical, mechanical, instrumental, etc.

Now, they are replaced by team 1, team 2, team 3, etc.

How to optimize your work center for productivity?

There are many different factors to consider when optimizing productivity. Some of these factors include,

- The sequencing of tasks

- The number of resources required for each task

- The dependencies between tasks

- The availability of raw materials

- The utilization of resources

Conclusion

The work center is where workers assemble and make products in a production line. Assembling and making a product can be broken down into various stages or tasks different people perform to create one final good.

For example, A worker may put together an iPhone while another assembles circuit boards for laptops; yet another person might design software that controls how these devices function.

Finally, when all the pieces come together, they form a finished product such as an iPad or MacBook Pro (iPad Air) - this is what we call “a work center” in manufacturing!

We hope this article helped explain the basics of the topic. Thanks for reading!