Packing is, in essence, the last stage before shipping. Packing departments are responsible for preparing picked material located in the picking department and labeling it for outgoing shipments.

This involves cutting open boxes to pack products inside them safely for transport so they do not break during transit. A packing department might also be charged with re-boxing items damaged by the selectors at the beginning of their process.

In this blog post, you will find details of packing department operations. It will also discuss what packing is, its types, methods, importance, and more.

What is Packing?

Packing is the process of protecting the products from damage and environmental factors during shipping. If packed properly, your product will arrive at its destination in good condition.

Key insights

- Packing is the safeguarding process of shielding products.

- The packing department is responsible for weighing and labeling, maintaining a clean packing space, and keeping records.

- Various types of packing are taking place in the department to safeguard materials.

- It is important to provide protection and security during storage, transportation, and handling.

- Choosing the appropriate packaging for your product is important, considering the diverse packing methods tailored to specific industries.

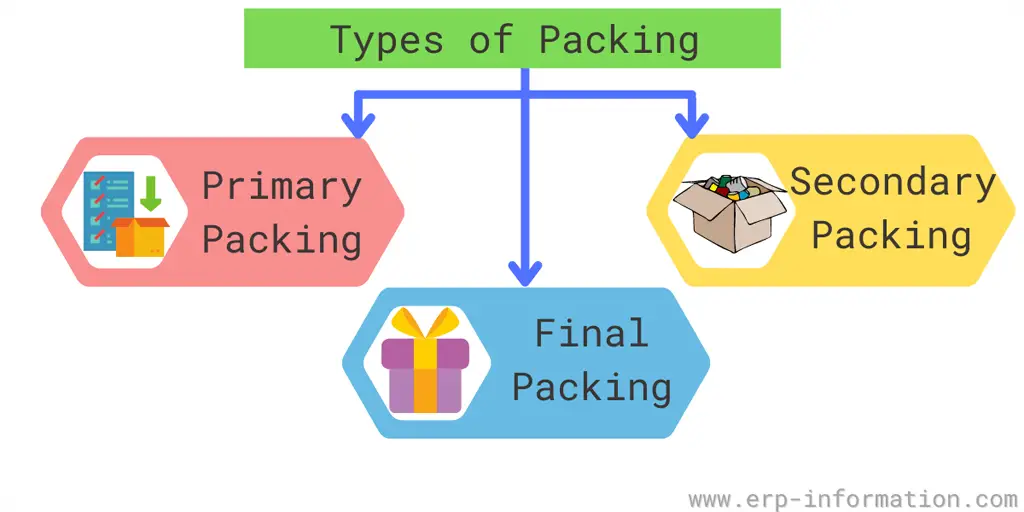

Types of Packing

Usually, three types of packing take place in the packing department.

- The first layer of packing happens in Primary packing. It protects and preserves the finished product. It also provides information about the products to the customer.

- Secondary packing appears outside of the primary packing. It gives extra protection to the products. In addition, it helps to identify the product quickly in the warehouse.

- Tertiary packing or final packing helps to handle, transport, and store the products. This packing is usually done with the cartoon box.

Packing Department Responsibilities

Same as the other department in the organization packing department also has some responsibilities. They are as follows.

- Take care of the cleanliness of packing materials.

- Find out the defective products, if any, and dispose of them.

- Do proper weighing and labeling of the products.

- Maintain clean and proper space for packing.

- Maintained documents for inventories and delivered items.

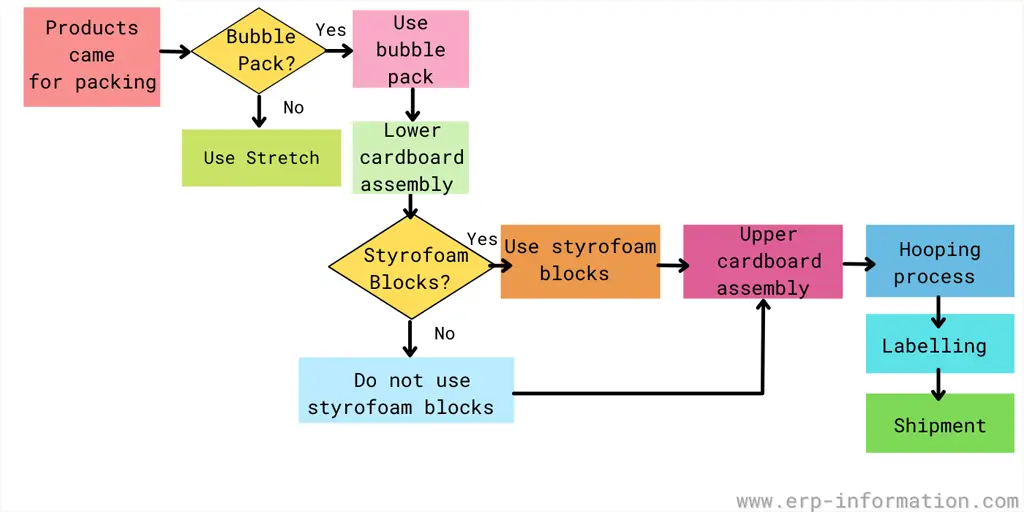

Flow chart

How do you Improve your Product Packaging?

If you are an employee of a company and working in the packing department, it is necessary to improve your packing system. Here are a few tips to improve product packaging.

- Determine who your customer is. According to the customer (male or female), you need to design your product packaging. At the same time, designing a package, you need to keep some points in mind. That is the information to be expected by your customer when looking for a product.

- Select the proper color and shape of the packaging element for your product.

- If your product is glass items or liquid, ensure that your packing materials are good enough to protect the products.

- The design on the packaging should tell about the product, and it should not display misleading information.

- Your packaging must be easy to open. Otherwise, sometimes it affects the product inside, losing its likelihood.

- Specify proper directions about the opening of the package, like ‘tear here’ or ‘twist here.’

- The first impression of a product is the packaging. Hence give proper budget and attention to that.

Importance of Packing

Product packing helps the manufacturer as well as the customer.

- Product packing helps the client to identify the product inside it. As a result, your packaging gives you a different identity and differentiates you from your competitors.

- Packaging helps to protect the product from dust, insects, and breakage. Some products like biscuits and juices must be packed tightly to protect them from environmental facts.

- It helps to carry and store the products easily.

- It helps to promote the products by advertising them. That means your packing itself helps the customer to know about your product.

- Packing some materials may be useful for re-use.

- Good packing reduces the losses of handling issues to reduce the marketing cost.

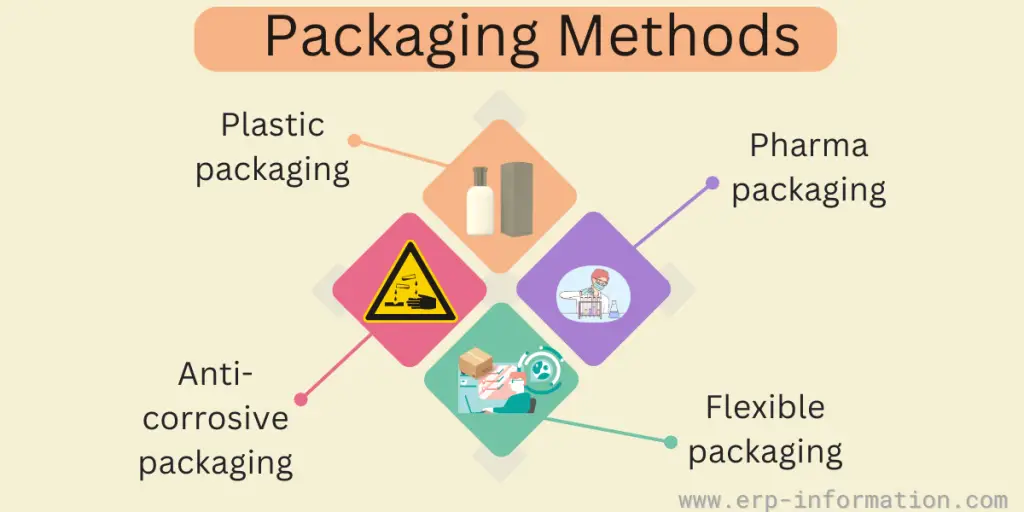

Packaging Methods

Here we will discuss different packaging methods used by the packing department of various industries.

Packaging methods differ from industry to industry. The most common packaging products are cartoon boxes, wrappers, envelopes, bottles, containers, etc.

But it is essential to decide which packaging suits your product. Here are some packaging methods.

1. Plastic packaging

This is the most commonly used packing method. Some products need airtight containers to avoid air and dust environmental effects. For that kind of product, plastic packaging is a good option.

This packing makes it easy to carry the products as it is very lightweight. For example, water, oils, milk, and yogurt products use plastic packaging.

2. Pharma packaging

Pharmaceutical companies practice pharma packaging for medicines. Pharma packaging provides safety to the drugs and helps identify the pills while handling and distributing.

3. Anti-corrosive packaging

It protects products from corrosion. Generally, this method is used for exported goods for long distances.

4. Flexible packaging

Usually, food products use flexible packaging to retain their taste and flavor.

Packing Department in Pharma Industries

In the pharma industry, the packing department plays a significant role. Packing in the pharma industry protects products and provides presentation, identification, usage, and information about the product.

Functions of packing in pharma

- Provides protection: The primary purpose of the packing is to protect the product from leaking, breaking, and spoiling.

- Helps to identify the product: The packing helps to identify the product.

- Provides information: The primary packing of the product offers complete information about the product, such as its usage, dosage, contents of the product, manufacturing date, expiring date, how to handle it, cautions, etc.

- Promotes the product: Packing helps to promote the product and attracts people.

Pharma industries do packaging tests also, which include the following tests.

- Drop test

- Vibration test

- Shock test

- Inclined impact test

- Revolving drum test

Pharma industries use the following material for packing the products.

- Plastics

- Glass

- Rubbers

- Metals

- Paper

- Cardboards

FAQs

What are the materials generally used for packing?

Many materials are used for packing goods depending on the product type, but it is common to use plastic, glass, steel, paper (paperboard), and wood. Aluminum is also often used because of its strong properties, like its lightweight and resistance to corrosion.

It’s always best to ask an expert in packaging before substituting one material with another due to dangerous hazardous risks.

Conclusion

Understanding the different departments when working in an organization is crucial. This blog post has explained what the packing department does and how they help keep your company running smoothly.