A process sheet is a document that provides all the steps for manufacturing products. Professionals can use it to ensure that each step in their workflow is appropriately completed.

The sheets are processed records, production documents, or shop orders. Whatever they’re called, these documents are essential for any manufacturing business to thrive.

Read the article to learn about the process sheet, its structure, importance, examples, and components outlined.

What is a process sheet?

A process sheet consists of manufacturing instructions for a specific batch, lot, or run.

It describes the operating parameters and settings for the equipment and facilities used and associated tooling or supplies. It contains part information, routing information, and operation detail information.

We all know a blueprint and how it works, and this sheet works precisely like a blueprint. This article finds out all about process sheets and how they are done.

A process sheet is a set of instructions that can be followed to achieve the desired goal. It is a manual that involves detailed procedures of tasks. This rule book focuses on systematically converting the raw materials into the final finished product and completing the job.

Importance of process sheet

It outlines the detailed mechanisms and describes every event in a step-by-step manner. That is where the importance of the manufacturing process sheet lies.

Firms with infrequent productions, a complex production pattern, or elaborate and irregular steps must follow a process chart efficiently.

It is developed way before a firm starts operating. That helps in having control over operations from day one.

Take, for instance, the case of AutoTech Innovations, a mid-sized car manufacturer struggling with production delays and quality control issues. After analyzing its operations, AutoTech implemented a detailed process sheet for its flagship electric vehicle line.

This process sheet not only outlined each step in the manufacturing process but also specified the tools, settings, and personnel responsible for each task. Within just six months, AutoTech saw a 30% reduction in production time and a 50% decrease in defects, illustrating the profound impact effective process documentation can have.

Such improvements not only streamline production but also significantly enhance product quality and worker satisfaction, showcasing the essential role process sheets play in manufacturing efficiency.

The components outlined in a process sheet

A process sheet for machining comprises two units,

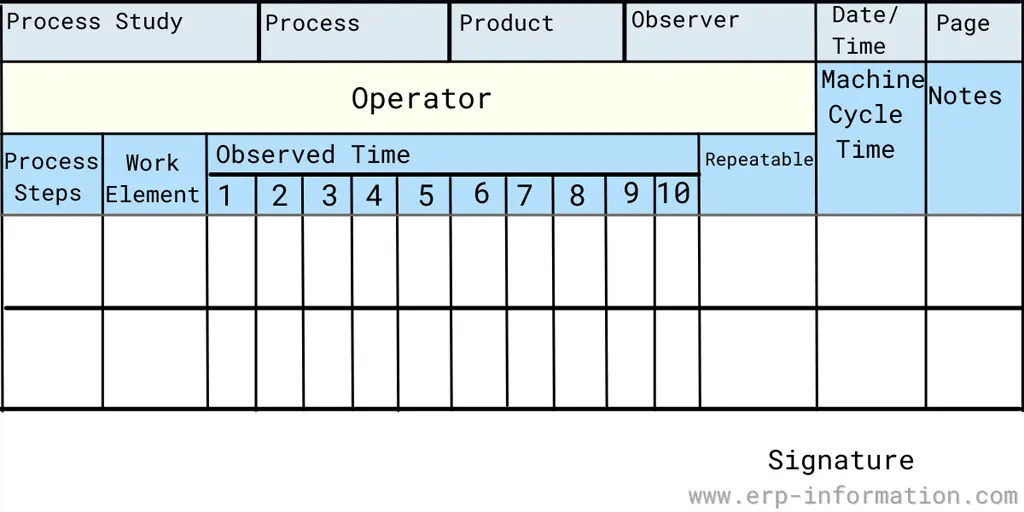

A route sheet

A route sheet is like a map that mentions the path and how the production and management activities proceeded.

An operation sheet

An operation sheet mentions the step-by-step programs to follow, outlines all the materials required for each task, and maintains a logbook of items that have arrived or are yet to come.

It is an irreplaceable tool. It keeps a tab on the entire work process it has been designed.

It keeps a count on the amount of raw material required, total processing time taken, the number of workers, specifications of the machines functioning, and so on for every separate component involved in the production.

Example

For example, a process sheet documentation for preparing a food item would include the recipe and each component mentioned in the required quantity.

It will also consist of cooking time with a detailed description of each task, the number of workers required for each job, and any remarks needed to be followed by previous experiences.

Calculate Level Production strategy using the online Level Production Strategy Calculator

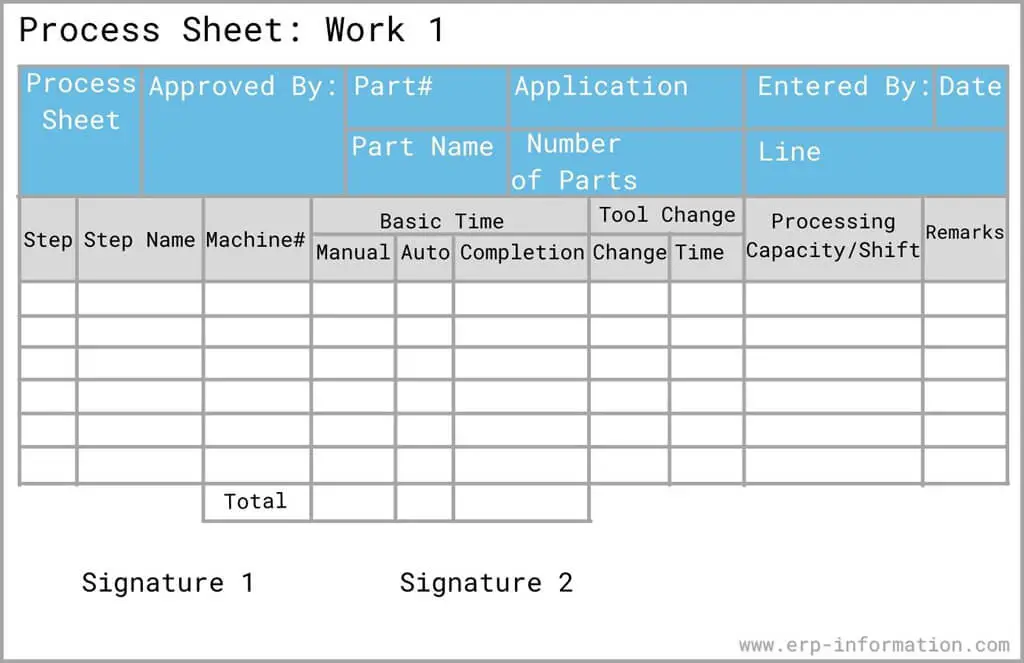

Structure of process sheet for manufacturing

- Outlining the sequence of work

- Figuring out the assemblies and sub-assemblies involved and drawing a map to figure out where each one fits

- Determining the number of units to be produced

- Machines, tools, and details of other instruments are required, along with further information like their efficiency, capacity, and run times.

- The sequence of these operations is drawn in detail on a map that develops a clear conception of how the raw material is converted into the finished product.

- A certain quality is required throughout the process; hence quality controlling instructions are also important.

- Instructions during packing and handling the products or movement during the processing are also mentioned.

What types of process sheet templates are available for business and project management?

There are a variety of templates available for business and project management, including:

- Business process documents and flowcharts are suitable for formal documentation and visual process mapping, available in formats like Excel and Word. You can find these templates on Smartsheet

- Versatile process map templates that work with Excel and Google Sheets, designed to help identify inefficiencies and enhance productivity. These are available on HubSpot

FAQs

Are process sheets only used in manufacturing?

No, process sheets are used in various industries including healthcare, hospitality, and retail.

How often should process sheets be updated?

These sheets should be reviewed regularly and updated whenever there are changes in the process or improvements to be made.

What are the common mistakes in creating process sheets?

Common mistakes in creating process sheets include:

Overlooking Details: Not providing enough detail about each step, which can lead to inconsistencies and errors in production.

Complex Language: Using technical jargon or complex language that may not be understood by all employees.

Lack of Standardization: Failing to standardize the process sheet format across the organization, which can cause confusion.

Inadequate Updates: Not regularly updating the process sheet to reflect changes in the production process or improvements in technology.

Poor Layout: Organizing information in a way that is not logical or easy to follow, potentially slowing down production and increasing training time.

Conclusion

Process sheets are an integral part of the manufacturing process. They can be used as a planning tool to plan wisely and efficiently, help with quality control, or be used simultaneously for various purposes by different departments.

The result is that it creates an economically efficient plan that will succeed through skillful execution.

Get more definitions of other ERP-related terms here.