To thrive in your business, you must focus on supply chain management. It’s a network and delivery performance is one of the critical aspects of it.

Delivery performance reflects the potential of the firm to meet customer expectations concerning time and cost. Find out more by continuing to read.

This post will provide an overview of delivery performance including contributing factors, formulas, and key performance indicators. You will also learn how to improve on-time deliveries and optimize delivery performance.

What is Delivery Performance?

Delivery Performance is an organization’s ability to supply goods and services as per the standards expected by its customers.

Delivery performance measures how well your organization fulfills orders and delivers products or services to customers. The success depends on how efficiently your teams carry out tasks within agreed delivery terms and using the resources and technology available.

Your operational capacity includes the resources, systems, and tools needed for smooth order fulfillment processes. To enhance capacity without expansion, optimizing delivery performance becomes crucial. This optimization boosts your ability to effectively provide goods or services to customers.

There are two types,

Operational

Measures how efficiently an organization can produce and supply goods or services per the standards.

Strategic

Look at long-range plans and whether they have been aligned with organizational goals.

Delivery Performance KPIs

Key performance indicators (KPIs) for Delivery Performance usually focus on operational factors such as order fulfillment rates, lead time, stock-outs, etc. However, you should also consider strategic elements such as customer satisfaction, market share, and brand equity. Let’s have a look.

- Order fulfillment rates – The Percentage of orders that are delivered on time or within the agreed timeframe

- Delivery lead time – The average time it takes from when an order has been placed until the customer receives it

- Delivery reliability – The Percentage of deliveries that are made within a specified time frame (order fulfillment rates)

- Delivery cycle time – The average time it takes from when an order has been placed until the customer receives the goods

- Delivery cost per unit – The average cost of delivering one product or service to a customer based on the total expenses incurred by your business

- Stockouts – The number of times a product or service is not available for sale due to stock-outs

- Customer satisfaction – The Percentage of customers who are fully or partially satisfied with the goods or services they have received

- Market share – The percentage of a particular market controlled by your business or its products

- Brand equity – The value of a brand name or trademark as determined by market research

Tools Needed to Measure Delivery KPIs

By incorporating these tools into your delivery performance strategy, you’ll be well-equipped to measure and improve key performance indicators such as order fulfillment rates, lead times, and stock-out occurrences, ensuring a streamlined and efficient delivery process. Tools are as follows:

- Shipping Status Tools: Use shipping status tools to gain real-time insights into the progress of your deliveries, helping you track performance and make necessary adjustments swiftly.

- Order Processing Tools: Implement order processing tools to streamline and optimize the order-to-delivery workflow, ensuring efficiency and accuracy.

- Lean Inventory Platforms: Lean inventory platforms help maintain optimal stock levels, reducing stock-outs and ensuring smoother delivery operations.

- Warehouse Management: Efficient warehouse management systems enhance order fulfillment rates and minimize lead times, vital KPI components.

- Bidding and Spending Analysis: By conducting bidding and spending analysis, you can control costs and identify cost-saving opportunities within your delivery operations.

- Supplier Management: Effective supplier management tools aid in building strong, reliable supplier relationships, contributing to consistent delivery performance.

- Demand Forecasting: Utilize demand forecasting solutions to anticipate customer needs, reducing delays and improving order fulfillment rates.

- Analytics and Reporting: Robust analytics and reporting tools allow you to visualize and assess delivery KPIs, helping you make data-driven decisions for improvement.

- Collaboration Portals: Collaboration portals facilitate communication and coordination among stakeholders, fostering a smoother delivery process.

- Transportation and Logistics Management: Transportation and logistics management software helps optimize routes, reduce lead times, and enhance overall delivery efficiency.

- Compliance and Auditing: Implement compliance and auditing tools to ensure that delivery operations adhere to industry standards and regulations, maintaining consistency in KPI evaluations.

Contributing Factors for Delivery Performance

1. On-time and in-full delivery from the suppliers

Once an order is placed, it is equally essential that the vendors provide the required items as promised without any changes in the quantity. That will ensure a smooth production process. To improve on-time delivery, the organization has to boost the operation of all the departments by improving planning, monitoring, and working efficiency.

2. Preparing proper manufacturing schedules

The firm will break down its overall production into various segments and concentrate on fulfilling each segment’s needs to ensure uninterrupted manufacturing.

3. Inventory management

This is important as it ensures enough raw materials for production and enough finished products to dispatch customer orders.

4. Transportation requirements

This will help to calculate and check the number of times the logistics were correct and, if they were wrong, how the business can aim to correct them to ensure no further mistakes.

Delivery Performance Metrics

The number of deliveries: This represents the total deliveries fulfilled within a month, potentially extending to a quarter or week. Additionally, you might factor in the average delivery count.

The number of on-time deliveries: Represents deliveries made punctually to customers, serving as a vital indicator of delivery performance quality.

Accuracy in order fulfillment can be measured by computing the order accuracy rate by comparing error-free orders against the total orders received.

The order accuracy rate formula is as follows.

Order accuracy rate = (Total orders – Error orders) / Total orders * 100

Transportation time: This metric overviews the time to transit the products from pick-up to drop-up locations. That helps to measure the speed of the drivers and the efficiency of the transporting routes.

The capacity of the means of transportation: It measures the vehicle’s capacity to transport the products. Calculate vehicle capacity by comparing available capacity and the total capacity of that vehicle. That helps to know the inefficiency in loading the products.

Average time per delivery: The average time taken to complete a delivery. It helps to measure the efficiency of the supply chain network.

The average delivery cost: It is calculated depending on the distance, products, and type of vehicle.

Delivery Performance Formula

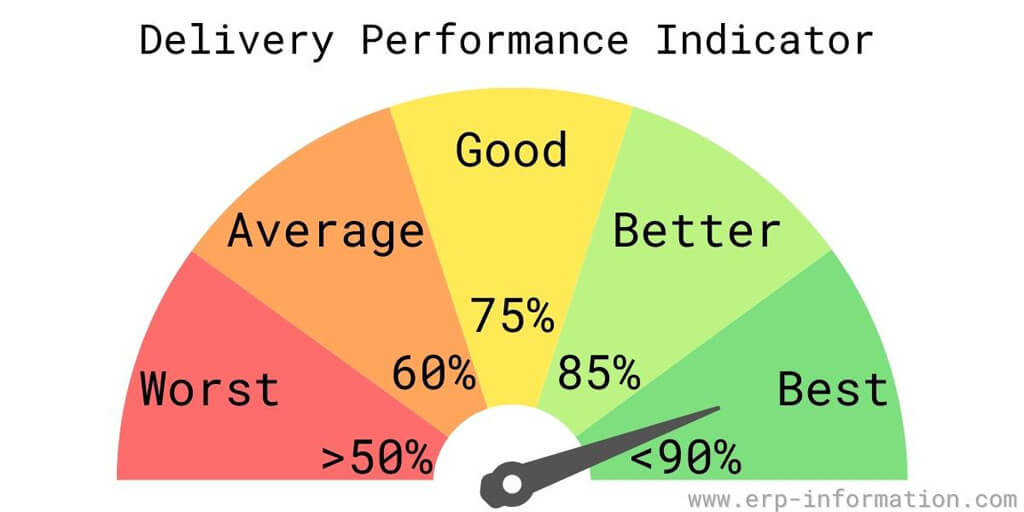

One of the essential key performance indicators to measure delivery is on-time delivery.

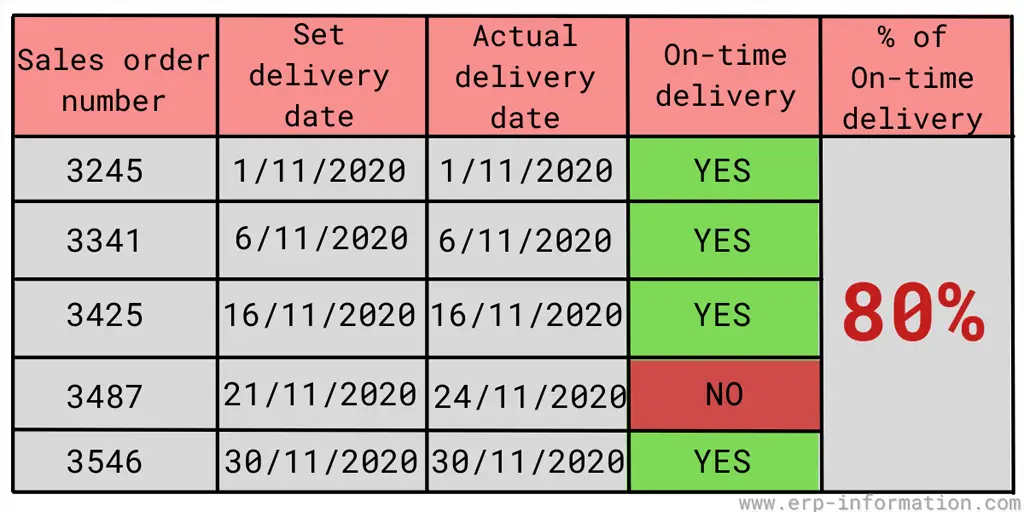

Generally, on-time delivery is measured as the number of products divided by the number of total products shipped monthly. The below image shows the on-time delivery calculation.

Delivery Performance (DP) = percentage of orders that were delivered on time / Total number of orders

Check our online delivery performance calculator.

Calculation of on-time delivery rate

Importance of On-time Delivery

- It is a major KPI of delivery performance.

- It helps to monitor and analyze the delivery performance and hence increases efficiency.

- It helps to build trust with your customers.

- It helps to satisfy the customer and improves customer relationships.

- It indicates the efficiency of the supply chain.

- Enhances your reputation in customer place.

How to Achieve On-time Delivery?

- Track and analyze the reason for previous late delivery.

- Analyze the factors contributing to late delivery and find out the root cause.

- Take corrective actions and concentrate on processing it to avoid late delivery.

- Define a plan and implement it for corrective actions.

- Observe the result and update it accordingly.

How to Improve Delivery Performance?

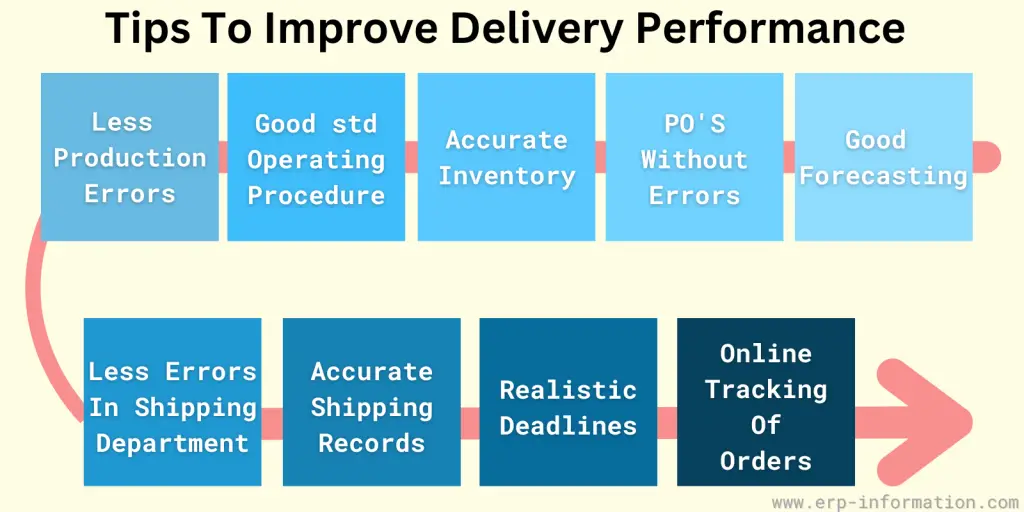

Late deliveries lead to poor delivery performance. However, delivery performance can be improved by the following things:

- Have good forecasting

- Have purchase orders without errors

- Maintain accurate inventory

- Maintain reasonable standard operating procedures

- Reduce production errors

- Reduce the picking and packing errors in the shipping department

- Do on-time delivery

- Maintain accurate shipping records

- Set realistic deadlines

- Provide online tracking to your customers for their orders

After determining the ideal performance level, the business needs to consistently assess and implement measures to uphold this standard, crucial for its credibility.

Identifying weaknesses and reducing stress can be achieved by establishing a learning index. Moreover, continual enhancement strategies will contribute to an overall improvement in delivery services.

FAQs

What is the delivery performance report?

It is a report that helps to view the shipment history, like drivers’ performance and delivery statistics.

For example, you can see how long it took for each driver to complete a delivery, how many deliveries each driver made, and the average time it took them to make a delivery.

It is also used to determine the issues with shippers, methods, and shipping procedures so that you can make any necessary changes. The report can also help you identify areas where your delivery process could be improved.

Conclusion

Delivery performance matters a lot in Supply Chain Management because it tells us if a company can deliver what customers want on time and without spending too much.

Understanding this helps companies ensure they’re doing a great job delivering to their customers. In this post, we’ve covered Delivery Performance in detail, talking about the important things to measure and what influences it. Hope the read helped you.