If you are a manufacturer or someone working in the business world, then you know how complex it can be to choose vendors. It’s crucial to make sure that you are selecting suppliers that are reliable and capable of providing quality products or services.

That’s where vendor rating comes into play. It provides an essential way for purchasers to evaluate potential vendors based on their performance history.

The vendor rating system assesses a potential vendor’s capabilities and determines their suitability for your needs.

This blog post will explain vendor rating, its criteria, how to calculate vendor rating, eight techniques for supplier evaluation, types of vendor rating, tips to improve vendor performance, and what you should look for when assessing a vendor.

Evaluate your vendor performance using our

Video Introduction

Vendor Rating Definition

Vendor rating is when the suppliers are provided with a status or a title based on several factors.

Vendors can earn a rating based on how reliable, punctual, and reasonably priced their goods are – not to mention the quality, of course!

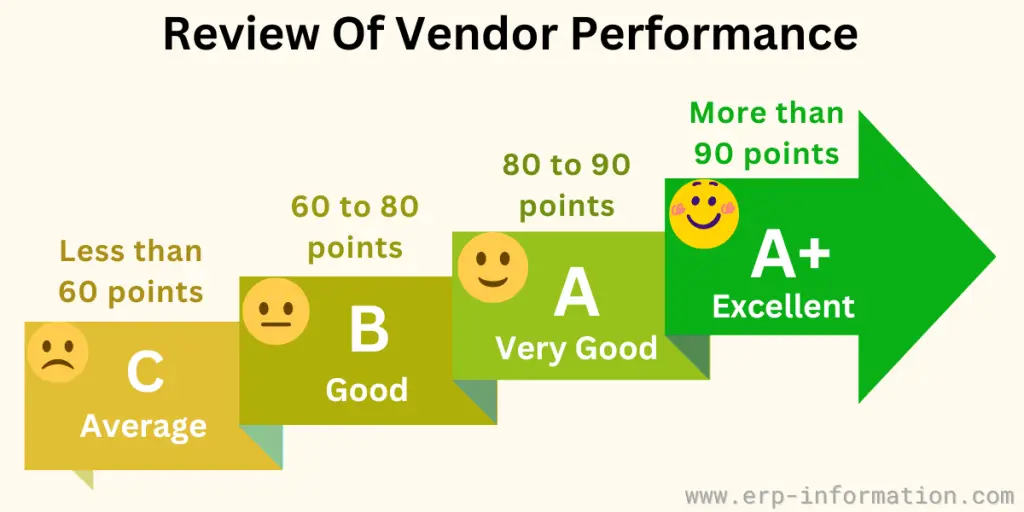

Ratings range from Good or Average all the way up to Best-in-Class – depending on performance and your company’s overall criteria for success.

Vendor Rating Criteria

When it comes to rating suppliers, there are key elements that buyers take into consideration.

Quality

The quality of the products or goods the vendor supplies is the main factor. The vendor can maintain good quality by improving production and having quality planning in the supply chain.

Quality factor consists following things.

- The supplier should follow the terms and conditions mentioned in the purchase order.

- The vendor’s products or services must meet the specifications mentioned in the proposal and purchase order request.

- The product failure rate should be within the appropriate limit.

- The vendor should do proper repair or rework.

- He should provide an adequate time duration for replacement.

Price

A company always wants to get the materials at less expense to reduce its manufacturing cost to increase its profit. Hence the vendor needs to set a competitive price for his products. It includes the following things.

- Stable price: The price of the product or service must be stable over time.

- Accurate price: There should not be much difference between the purchase order and invoice prices.

- Prior notice about price changes: They should inform about price changes in advance.

- Billing: They must provide easily readable and understandable bills.

Evaluate purchase order finance using our Purchase Order Financing Online Calculator.

Delivery

The supplier has to develop the ability to deliver the goods on a scheduled date. This factor consists following things.

- Lead time: Lead time is between the actual delivery day and order placement day. The shortest lead time helps to get a good impression of the supplier. The vendor should deliver products on or before the promised date.

- Quantity: They must deliver the correct amount of products as mentioned in the contract.

- Packing and documentation: Packing of the products must be suitable, studied, and undamaged. The vendor should provide proper documents along with the delivered products.

- Emergency delivery: The vendor must be able to deliver products in case of emergency requirements.

You can calculate your vendors’ delivery performance with the Delivery Performance Online Calculator.

Service

It is one of the crucial criteria for the suppliers. They have to provide good service by providing an updated catalog, pricing, technical information, etc.

- The vendor must have the ability to handle complaints effectively.

- The vendor should provide technical support for installation, maintenance, and repair.

- The supplier should support in the emergency condition of product failure or repair.

- The supplier should find the solution to the problem on time.

The supplier rating system is a by-product of the just-in-time approach.

Just in time (JIT) is a lean manufacturing methodology designed to reduce the waste of time and resources by receiving goods only as needed. The JIT process was developed in Japan to maximize limited natural resources.

One of the essential objectives of the supplier assessment system is that it helps buyers carefully choose suppliers for future transactions.

The available data can also help to negotiate better and help the buyer with any information that might be useful during the process.

Composite Vendor Rating

Composite suppliers rating means rating vendors based on their product price, service, delivery performance, and quality of the product or services.

Composite vendor rating procedure

Following are the four primary rating criteria for composite rating.

- Quality rating: Rate the quality of the product by considering two factors. They are quality acceptance and certification.

- Quality acceptance means material purchased by the vendor should pass the first inspection level only so that we can consider that the quality of the product is good.

- The material should have some quality certification like ISO(International Organization for Standardization) certification, IRS, ABS, DQA(WP), and DQA(N).

- Price rating: Compare the price of the present vendor with other vendors and compare the material’s current worth with the material’s average cost for a chosen period.

- Delivery rating: Rate the delivery performance of the vendor by comparing the actual delivery date with the predetermined delivery date.

- Service rating: Rate the service based on the support provided by the vendor during post and pre-purchase orders and consider the warranty period.

This way, do the composite rating by rating all the above factors and choose the best vendor for your business.

Benefits of Vendor Assessment

The following are significant benefits.

- It helps the buyer understand the vendor in every critical aspect, and it helps to know whether the vendor is suitable to deal with. It does not deal with prejudices and word-of-mouth. It is more dependent on data.

- It helps the buyers to strike the right kind of communication required.

- It ensures a consistent vendor performance standard with updated performance reviews.

- It helps the buyer identify areas of weakness in the vendor’s performance and allows the buyer to take corrective actions.

Disadvantages of Vendor Rating

Rating your vendor helps you to enhance your supply chain. But its significant disadvantage is losing trust.

When you evaluate and rate your vendor, they might feel you do not trust them.

It may impact your relationship with your vendor/supplier. However practical supplier evaluation helps the supplier to perform well.

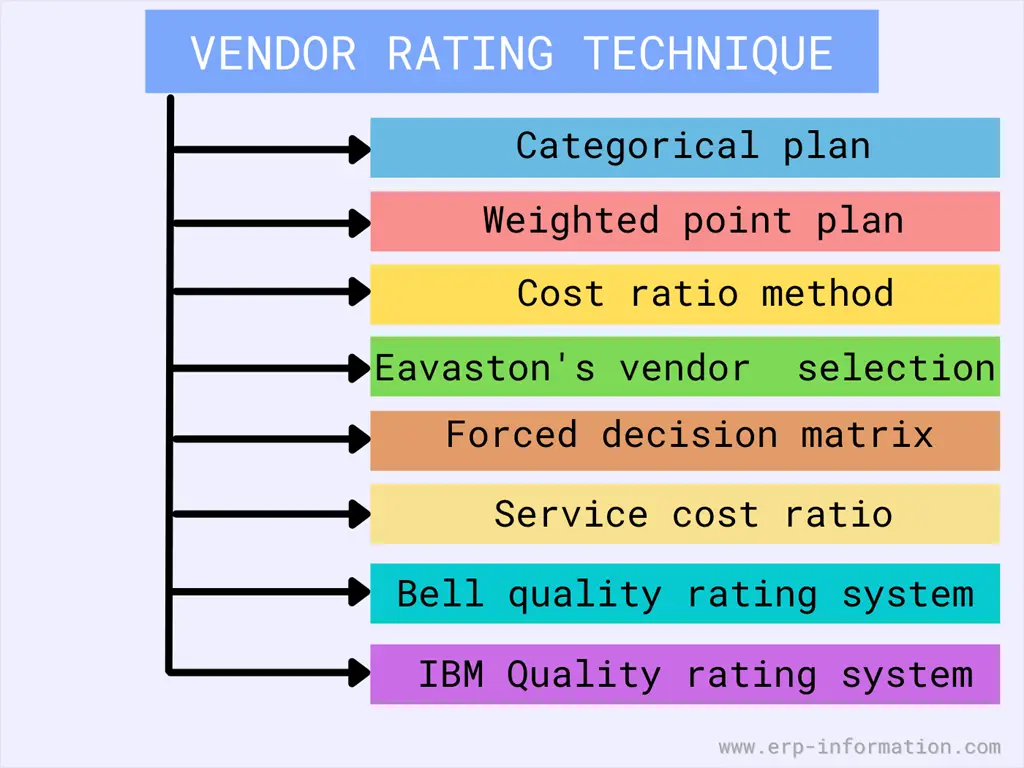

Supplier Evaluation or Vendor Rating Techniques

- Categorical plan: Managers from various verticals list crucial factors for a vendor and assign performance ratings to each vendor in categorical terms such as “good”, “neutral”, and “poor”. They give ratings based on their personal experiences, and vendors are compared based on the same.

- Weighted point plan: Factors are categorized, and weight is assigned to each factor based on vendor performance.

- Cost ratio plan: Supplier rating is based on different costs incurred for procuring the materials from other suppliers. The cost ratios are ascertained for the various rating variables such as quality, price, and timely delivery. The cost ratio is calculated in percentages based on the total individual cost and the total value of the purchase.

- Eavastons’s vendor selection: Previous vendor performances are considered for choosing them.

- Forced decision matrix: The attributes of rating like quality, service, price, reliability of the vendor, and lead time of supply are identified first. Then these factors are compared between themselves. If something is more important, it will be assigned with one’s weight, and the other will be zero for evaluation.

- Service cost ratio: Subjectively measuring other intangible aspects of a supplier’s services. Aspects to consider could be labor stability, financial stability, flexibility in production for rush orders, research, and development (R&D).

- Bell quality rating system: This is developed by the Bell helicopter company Lot Quality Index(LQI). It assesses lots received against lots rejected. X/L gives LQI. Where, L = total number of lots received during the period, X = (L1 x 1.00) + (L2 x 2.10) + (L3 x 2.90) + (L4 x 3.10)+ (L5 x 3.90)

- L1 = number of lots acceptable as received.

- L2 = number of lots rejected by sampling inspection but labeled.

- L3 = number of lots rejected and dispositioned, rework at supplier’s end.

- L4 = number of lots rejected and dispositioned, returned, not usable.

- L5 = number of lots rejected and dispositioned rework at Bell Helicopter Company.

- This formula can be modified easily to suit the needs of a particular company.

- The IBM quality rating system: It uses quality costs as the basis for rating vendors. The formula is VGR= ((Desired cost of inspection)/(Actual cost of inspection)) x 100

Types of Vendor Rating

Generally, there are three types of supplier evaluation.

Evaluation with the help of records

In this type, you can use documents such as financial reports, logbooks, and journals to collect information about the supplier. Then, depending on the evaluation result, you can choose a suitable vendor for your business.

After the event evaluation

You must find answers to questions like what happened. How did it happen? How did it fail? This data helps you to evaluate the vendor.

Before the event evaluation

In this type, collect the historical data of the vendor to find his capabilities.

Vendor or Supplier Selection Process

No matter which business you run, the vendor plays a vital role in your company. So, how do you select a good vendor or supplier?

You can select a good vendor by evaluating the vendor. Below is the vendor evaluation process.

- First, set performance criteria for the vendor. For example, consider your vendor’s qualities, the vendor’s financial condition, complaint history, quality management system, production process, and product quality. Based on these things, you can establish the performance of the vendor.

- List out the vendors who meet your criteria. Now choose your vendor from that list by considering his services.

- Keep on evaluating vendors quarterly/ yearly. Periodically do the audit to monitor the vendor.

- Depending on the resources available, assign a person or a team to assess the vendor frequently.

- Consider the type of relationship that the vendor has with you while selecting your vendor or supplier.

Vendor Rating Example

Let us rate two companies, A and B.

Factors considered are quality, price, and delivery.

Weights for each of the above factors. That is

- Quality – 60%

- Price – 20%

- Delivery – 20%

If we multiply each factor’s values by their weights, we can derive ratings and compare which is better.

Company A inputs:

Total quantity supplied: 10 units, total quantity accepted: 8 units, price per unit: $10, Delay in delivery 20% time delay.

Quality rating = (8/10)X100 = 80%

Price rating = (Price Ratio Lowest / Simpler Price) x 100

= (10/10)X100 = 100%

Delivery rating = 100 – 20 = 80%

weighted vendor rating of company A = (80X60+100X20+80X20) = 84

Company B inputs:

Total quantity supplied: 20 units, total quantity accepted: 18 units, price per unit: $16, Delay in delivery 10% delay.

Quality rating = (18/20)X100 = 90%

Price rating = (Price Ratio Lowest / Simpler Price) x 100

= (10/16)X100 = 62.5%

Delivery rating = 100 – 10 = 90%

weighted supplier rating of company B= (90X60+62.5X20+90X20) = 84.5

Though the price per unit of Company B is more than Company A, Company B still wins because of its overall rating.

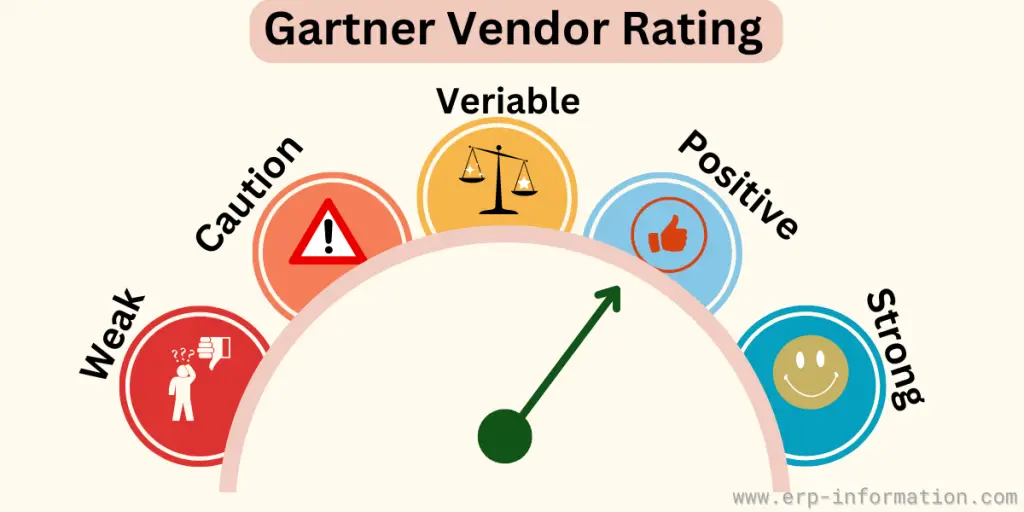

Gartner Vendor Rating

Gartner vendor rating is a method that provides the best content to the customer to evaluate vendors or providers for mutual benefits.

It considers things like,

- Product/Service offered by the vendor

- Support provided by the vendor

- The pricing structure of the product or services

- Technology

- Strategy

- Corporate Viability

It rates the vendor from weak to strong.

- Strong: Vendors with the best focus, quality products or services, and a good market position will come under this category. The customer feels comfortable and shows interest in continuing the relationship with the vendor. They consider this provider as the best choice for new investments.

- Positive: Vendors with good focus and quality products/services will come under the positive category. Customers can continue working with vendors for planning investments.

- Variable: Average vendors will come under this category. The customer should consider the maturity of the vendor and the short-term &long-term effects of the relationship.

- Caution: Poor service providers will come under this type. The customer should understand the limitations of the vendor and eventually plan based on risk and future business effects.

- Weak: Vendors with inferior performance will come under this category. Customers should consider this vendor only for planned investment and eventually arrange another vendor.

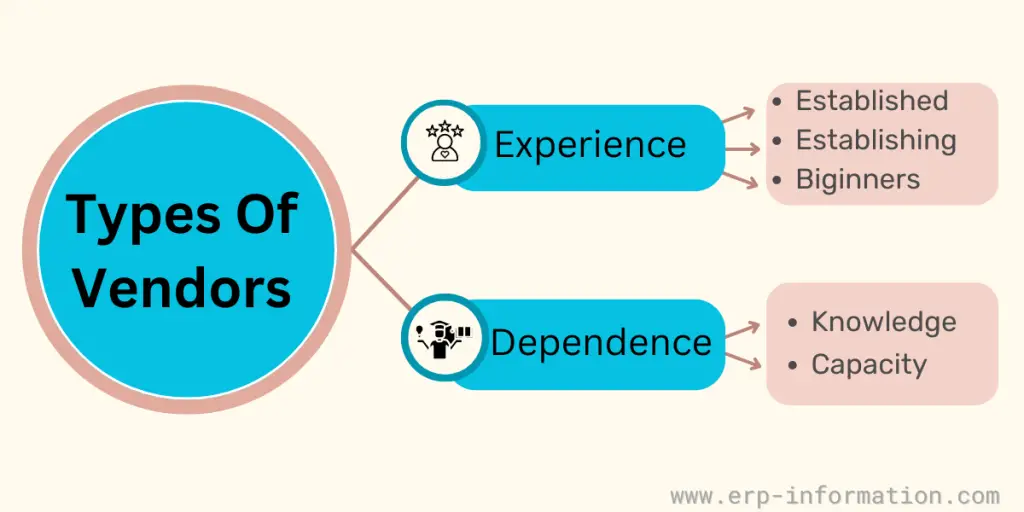

Types of Vendor

To choose a good vendor for your business, check out the type of vendor in the market. We can differentiate the vendors depending on their experience and dependence shown in the below image.

You need to think about the experience and knowledge of the vendor when deciding to work with them.

10 C’s of Supplier Evaluation

10C’s of supplier evaluation is defined by Dr. Carter, who is the DOSS consultant. In 1995, he wrote an article in the Journal of Purchasing and Supply Management. In that, he defined 7C’s of vendor evaluation and added three more C’s later.

According to Carter, an organization must consider these 10 C’s while rating or evaluating its vendors.

They are:

- Competency – How competitive is the supplier?

- Capacity – How capable is the supplier of fulfilling requirements?

- Commitment – Is the vendor committed to supplying expected quality products or services?

- Control – Does the supplier have control over policies and procedures?

- Cash – What is the financial status of the supplier? Are they able to supply raw materials on time?

- Cost – What is the cost offered by the supplier for their products? Is it worth it?

- Consistency – Is the supplier able to provide quality products or services consistently?

- Culture – What is the business culture of the supplier? Is that culture match your culture?

- Clean – Does the vendor follow sustainable practices and green management rules? Is the vendor’s business ethical?

- Communication – What is the communication process? What is the response time?

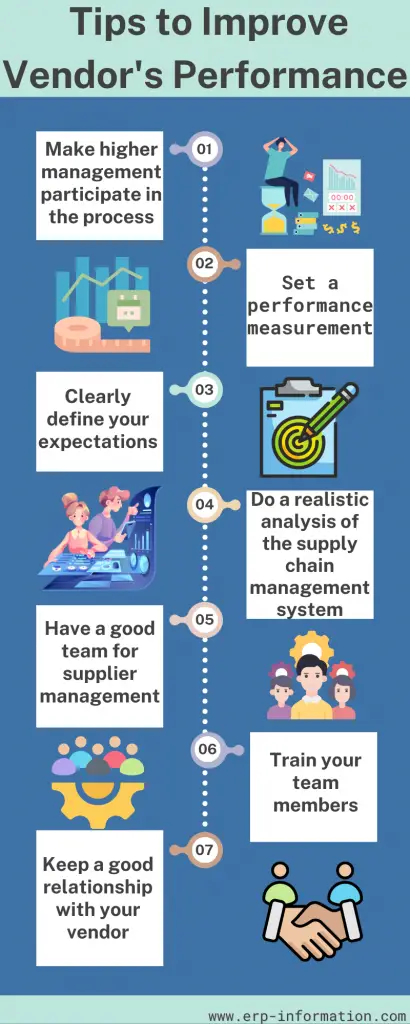

How do you Improve your Vendor’s Performance?

Here is a list of tips to encourage and improve supplier performance ratings.

Make higher management participate in the process

It is essential because you can only get sufficient resources to execute this process if you involve higher management.

Set a performance measurement

Set key performance indicators (KPIs) and make sure that they cover areas like vendor service, vendor response capacity, vendors’ managing skills, and sales support. Let them know that you are monitoring them and reviewing their performance.

Clearly define your expectations

Communicate with the vendors about what you want and what they need to focus on. For example, provide a unique requirements list to each vendor instead of giving all vendors a general requirements list so they can quickly identify your needs.

Do a realistic analysis of the supply chain management system

Explore your purchase and supply chain management practices to discover their strengths and weaknesses.

Have a good team for supplier management

Based on the complexity of the supply chain, have team members for quality checks, logistics, planning, and engineering. In addition, let the team members share supplier management plans and targets so that this team approach helps to boost vendor performance.

Train your team members

Train them about approaching the vendors, making them understand your needs, and reaching their goals. While training, concentrate on what you want from your vendors and how to approach them.

Keep a good relationship with your vendor

Analyzing and evaluating the vendors is insufficient. Instead, have a friendly relationship with them. Visit their place, and greet them when they come to your place. It improves their confidence and performance.

Future Trends of Vendor Rating

AI-powered vendor assessment

In the future, AI-driven vendor selection will revolutionize how businesses identify partners. Businesses use Artificial intelligence (AI) and machine learning (ML) algorithms to automate vendor assessment processes.

AI can analyze vast amounts of vendor performance data, and provide predictive insights into vendor behavior and performance based on historical performance, responsiveness, and adaptability.

Evolving metrics for sustainability

Sustainability metrics will redefine vendor assessments. Beyond cost and quality, vendor ratings will encompass eco-friendly practices, societal contributions, and ethical standards. Organizations will prioritize partners committed to reducing carbon footprints and fostering social responsibility.

Dynamic real-time vendor ratings

The move towards real-time data analytics might lead to more dynamic and continuously updated vendor ratings. This could involve utilizing IoT (Internet of Things) sensors, blockchain, and other technologies to gather instant feedback and performance data from supply chain interactions.

Enhanced risk management integration

Vendor ratings might become more integrated with risk management systems. Future trends could see the inclusion of predictive risk modeling, enabling organizations to identify potential risks associated with vendors early on and take proactive measures.

Collaborative vendor rating platforms

There might be an increase in collaborative vendor rating platforms where multiple organizations within an industry or sector share anonymized vendor performance data. Such platforms could offer comprehensive insights into vendor behavior across the supply chain ecosystem.

Predictive analytics for performance evaluation

Anticipating potential performance difficulties before they arise, predictive analytics will redefine vendor evaluations. This strategic analysis of patterns and trends empowers businesses to forecast and prevent supply chain disruptions, allowing proactive adjustments for uninterrupted operational flow.

Blockchain technology in vendor rating

Blockchain integration will ensure transparency and trust in vendor ratings. Immutable ledgers will secure data, fostering transparency in performance history and enabling shared, tamper-proof records among multiple parties.

FAQs

What is the product vendor’s meaning?

A product vendor is a business that sells products to other companies. The term “vendor” typically applies to any company selling physical or digital products. In addition, vendors often provide their customers with branding, marketing, distribution services, and products.

What are the drawbacks of having multiple vendors?

Vendor evaluation helps you keep away from multiple suppliers. Some of the drawbacks of having numerous vendors are

– You may face problems while sharing information.

– If you have many vendors, the order volume will be less. Hence there will be no chance of bargaining.

– It is challenging to have a good relationship with all the suppliers. Unfortunately, that leads to less interest by the supplier in your organization, which may affect responsiveness during an emergency.

– Having many vendors consumes more time and money while managing, executing processes, and negotiating contracts.

Conclusion

Many supply chain management solutions (SCM) are available with an inventory module that includes supplier rating and evaluation mechanisms.

Management should implement the system company-wide to evaluate suppliers accurately. In addition, the review should be based only on measurable performance instead of opinions.

We have provided you with helpful techniques that will help guide your assessment process to confidently rate a new supplier or evaluate one of your current suppliers when necessary.

References: