The supply chain is becoming complex and globalized, making it difficult to keep track of inventory and shipments.

The traditional supply chain model is no longer adequate for the modern business world. Companies are struggling to keep up with the ever-changing demands of consumers and suppliers.

Supply chain 4.0 offers a new way to manage your supply chain using cutting-edge technology and innovative practices. This platform gives you real-time visibility into your inventory and allows you to collaborate with suppliers and customers in a secure environment.

This blog will explore all you need to know about supply chain 4.0, including what it is and its key features. We will also explore its impact on businesses and consumers, its trends, potential risks, and use cases.

What is Supply Chain 4.0?

It is the digitization of the supply chain. Data is collected and analyzed digitally to provide insights that help individuals and organizations make better decisions. The goal of supply chain 4.0 is to create a more efficient, effective, and resilient supply chain.

It uses technologies developed by Industry 4.0, including big data, the internet of things, cloud computing, and cognitive computing.

Industry 4.0 aims to create a more flexible and responsive production environment by connecting machines, sensors, and people in an intelligent network that can automatically adapt to changing circumstances.

That allows for real-time monitoring and optimization of processes and the rapid deployment of new products and services.

Key Features

To keep up with the new trends and technologies, companies must be aware of the critical features of supply chain 4.0. Some of these features include:

Data Analytics

By analyzing large amounts of data, companies can identify patterns and trends that would otherwise be difficult to see. That enables them to make more informed decisions about where to allocate resources and how to optimize their supply chains.

Robotics and Automation

Automation allows companies to automate tasks such as packing and labeling, which can help them save time and money. Additionally, they can help improve the accuracy and reliability of operations.

Focus on Sustainability

Companies are now looking for ways to reduce their environmental impact and improve their social responsibility.

That includes using more sustainable materials and designing more efficient processes. That means looking for ways to reduce waste and pollution throughout the supply chain.

Cloud-based Solutions

Cloud-based solutions allow companies to access information anytime. It allows the flexibility to adapt quickly to changing conditions and make real-time decisions.

Collaboration

By working together, companies can share ideas, resources, and knowledge, which can help them streamline their operations and improve their performance.

Supply Chain 4.0 Impact on Businesses and Consumers

With the advent of the supply chain, businesses and consumers can expect several benefits.

- It will allow businesses to optimize their production and distribution processes, increasing efficiency and lowering costs. That will lead to lower prices for consumers and improved product quality.,

- Increased transparency of having a more interconnected supply chain will allow consumers to understand better where their products come from and how they are made. This increased transparency can also help consumers make more informed choices about the products they buy.

- It will help businesses better respond to changing market conditions, enabling them to be more agile and competitive.

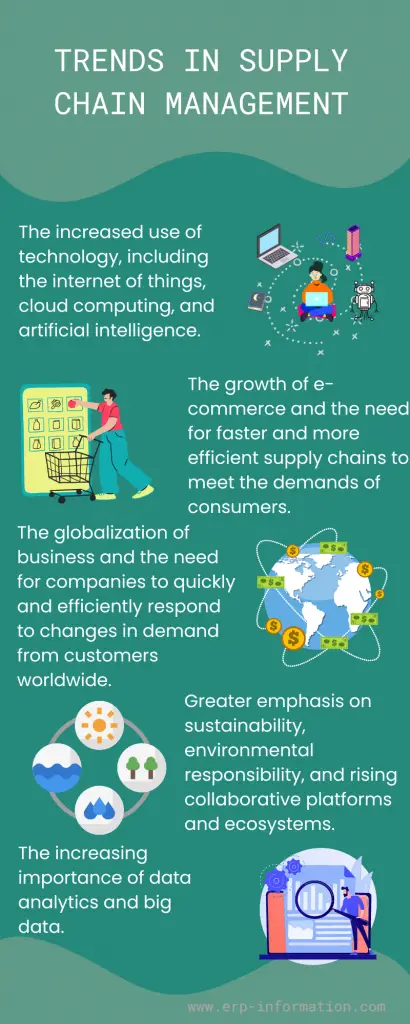

Trends in Supply Chain Management

The trends in supply chain management are the following:

- The increased use of technology, including the internet of things, cloud computing, and artificial intelligence.

- The growth of e-commerce and the need for faster and more efficient supply chains to meet the demands of consumers.

- The globalization of business and the need for companies to quickly and efficiently respond to changes in demand from customers worldwide.

- Greater emphasis on sustainability, environmental responsibility, and rising collaborative platforms and ecosystems.

- The increasing importance of data analytics and big data.

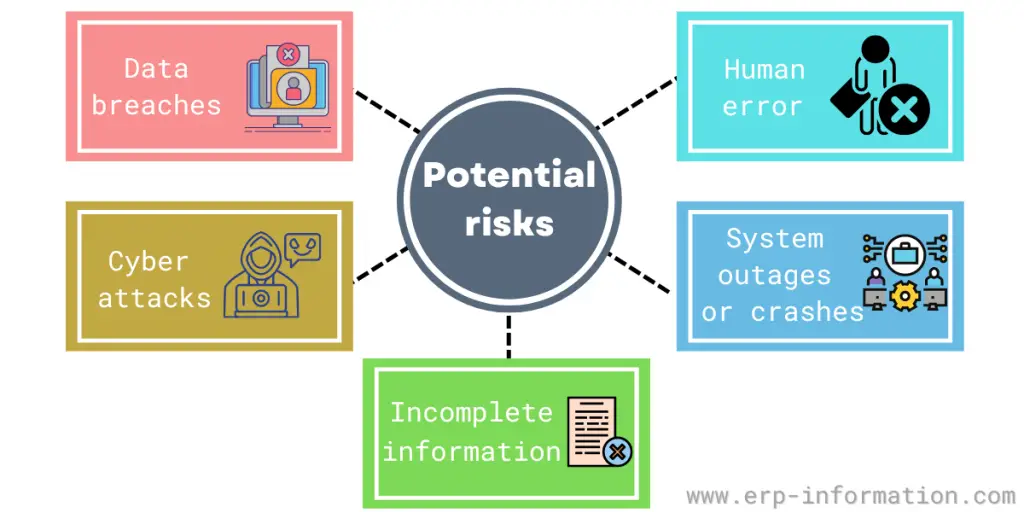

Potential Risks

- Data breaches: The increased use of Cloud-based technologies and the interconnectedness of supply chains can create opportunities for data breaches. Hackers may be able to access confidential data by attacking vulnerable systems.

- Cyber attacks: Supply chains are increasingly vulnerable to cyber attacks, which can disrupt business operations, steal sensitive information, or damage critical infrastructure.

- Incorrect or incomplete information: The expanded use of data and analytics in supply chains can lead to inaccurate or incomplete information if not properly managed. That can cause financial losses.

- System outages or crashes: System outages or crashes can occur when IT systems are overloaded or critical data is lost or corrupted. That can cause losses in revenue and productivity.

- Human error: Inaccurate orders, incorrect shipping information, and misplaced items can all lead to delays and financial losses.

Use Cases

Industries that can use supply chain 4.0 include the manufacturing, retail, automotive, aerospace, and defense industries. It can help these industries manage their supply chains more effectively and efficiently with the following operations.

Advanced forecasting

By analyzing past sales data with the help of big data and analytics, retailers can develop models that predict future demand for particular items.

This information can optimize inventory levels and ensure that the right products are available when customers need them.

Logistics and routing

By using GPS-enabled devices, retailers can track their shipments’ location in real-time, making better decisions about delivery routes and inventory levels.

In addition, advances in robotics and automation make it possible to streamline the logistics process, resulting in faster and more efficient deliveries.

Warehouse management

By implementing modern technologies such as barcode scanners and RFID tags, warehouses can become more efficient and accurate in inventory management.

In addition, automated sorting systems can help reduce the time needed to process orders and get products to customers quickly and efficiently.

Traditional Supply Chain vs Supply Chain 4.0

| Traditional Supply Chain | Supply Chain 4.0 |

| The traditional supply chain is centralized. | It is decentralized. |

| In traditional supply chains, data is siloed and not shared between departments or companies. | Here, information is shared and collaborated to create a more efficient system. |

| In traditional supply chains, there is a lack of transparency and communication between stakeholders. | In supply chain 4.0, transparency and communication are improved through technology such as blockchain and RFID tags. |

| Traditional supply chains are slow to adapt to changes. | It can quickly adapt to changes through technology and automation. |

Conclusion

Supply chain 4.0 is the future of how businesses and consumers will interact with the supply chain. It offers many advantages for both groups, including increased efficiency, visibility, sustainability, and security.

However, some potential risks are also associated with it that businesses must be aware of. By understanding the key features, impacts, trends, and threats, companies can decide whether to adopt them into their operations or not.

Reference