If you’re in the warehousing and logistics business, having an efficient warehouse layout is key to running your business smoothly. A well-designed warehouse can help you save time and money, while a poorly designed one can lead to chaos and inefficiency.

This blog post will discuss warehouse design and layout ideas and also types of warehouse layouts. It also gives fifteen tips for designing an efficient warehouse layout. Read on to learn more!

What is warehouse design?

It is the process of creating an optimized warehouse layout that enables the efficient flow of products from the warehouse to their destination.

It also includes determining warehouse operations, such as product storage, inventory control, and warehouse management. A well-designed warehouse can help reduce costs and improve customer service.

Importance

Good warehouse design is critical for businesses because warehouse space is expensive, warehouse operations are complex, and warehouse workers need to be productive.

Therefore, companies must optimize the warehouse layout for efficiency before acquiring warehouse space or undertaking warehouse projects.

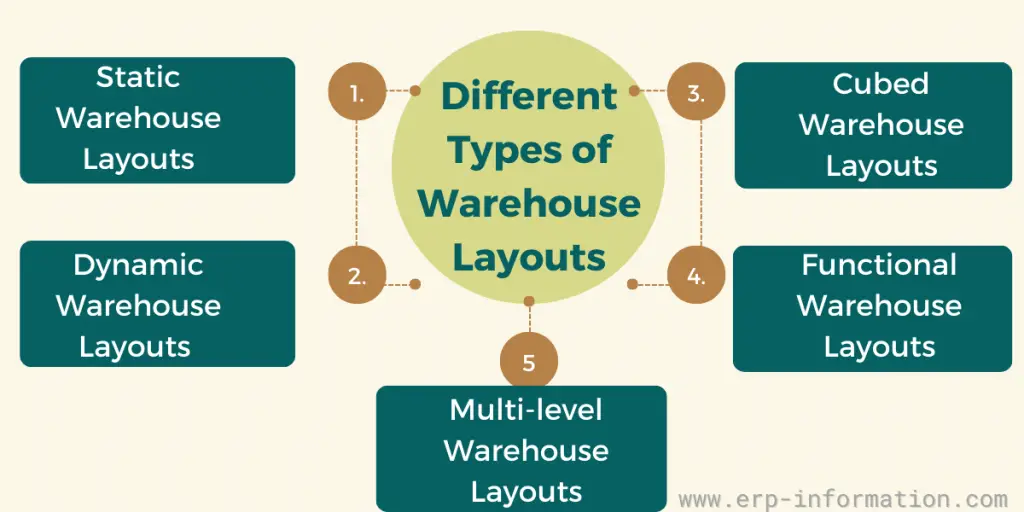

What are the different types of warehouse layouts?

Warehouse layouts come in many different types, depending on the warehouse’s purpose and size. However, some of the most common warehouse designs include static layout, dynamic layout, cubed-style layout, functional warehouse layout, and multi-level warehouse layout.

Static warehouse layouts

Static warehouse layouts are the simplest to implement but can take up more warehouse space than other warehouse layouts. This warehouse layout is based around long rows of product shelving, with each shelf containing a single type or category of products.

Dynamic warehouse layouts

These are more complex and involve moving items between areas within the warehouse as needed. However, it is a great option for warehouses with multiple types of products.

Cubed warehouse layouts

Cubed designs involve storing similar items in cubes or cases that are often stacked to conserve space. This layout can be cost-effective and efficient, making organizing warehouse inventory easier.

Functional warehouse layouts

Functional warehouse layouts involve creating designated areas for specific tasks such as order picking, packing, and shipping. This warehouse layout makes it easier to locate specific items and move them through the warehouse quickly.

Multi-level warehouse layouts

It involves creating different levels of warehouse storage, allowing for more efficient use of space. This warehouse layout design also allows for greater operational flexibility since goods can be moved quickly from one level to another.

Seven steps to begin warehouse layout design

Warehouse layout design will be easy if you follow these seven steps.

Decide on the type of warehouse you need

Warehouse types typically fall into three categories: distribution, production, and storage. Each one has its own specific needs.

The type of warehouse you need will depend largely on how your warehouse will be used, so it’s important to make this decision before proceeding with any other warehouse layout design steps.

Look at the surrounding area

It’s important to consider the surrounding area when designing warehouse layouts. Factors such as nearby roads, buildings, and other structures should be considered when designing warehouse layouts. That will help you create a warehouse layout that works best in its environment.

Analyze the space requirements

Once you’ve decided on the warehouse type, you’ll need to measure the warehouse and analyze its space requirements. That includes considering factors such as how much space you need for storage, production, distribution, and loading/unloading docks.

Outline warehouse processes

Before beginning any warehouse layout design process, all processes must be outlined and clearly understood so the warehouse can be designed accordingly.

Choose the warehouse layout

With warehouse processes outlined and the warehouse space requirements analyzed, it’s time to choose a warehouse layout that best suits your needs.

Ensure everything is safe and conforms to government regulations

Safety is paramount when designing warehouse layouts. Therefore, it’s important to ensure warehouse layout designs follow all applicable safety regulations and standards.

That includes ensuring warehouse aisles are wide enough for vehicles to pass through, creating fire-proof areas, and installing appropriate safety equipment.

Test and refine warehouse design

Once you have the warehouse layout in place, testing and refining it to ensure it works as intended is important. That involves testing how warehouse processes can be labeled, organized, and operated efficiently.

Following these seven steps will help get you started on warehouse layout design. With some planning, your warehouse can become an efficient, organized, and productive space.

Best three warehouse layout designs

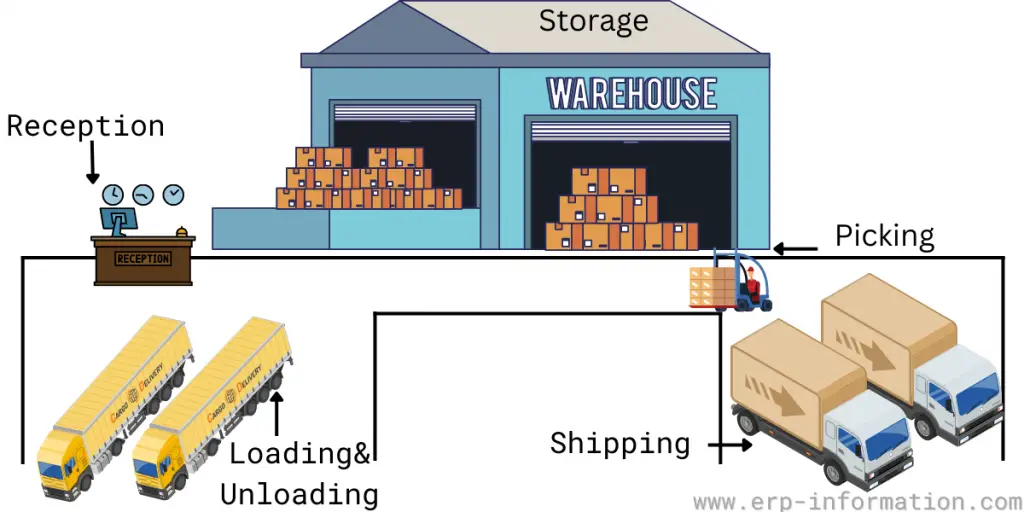

U-shaped design

The U-shaped warehouse layout is a popular design comprising incoming and outgoing (shipping) areas side by side. as shown in the image.

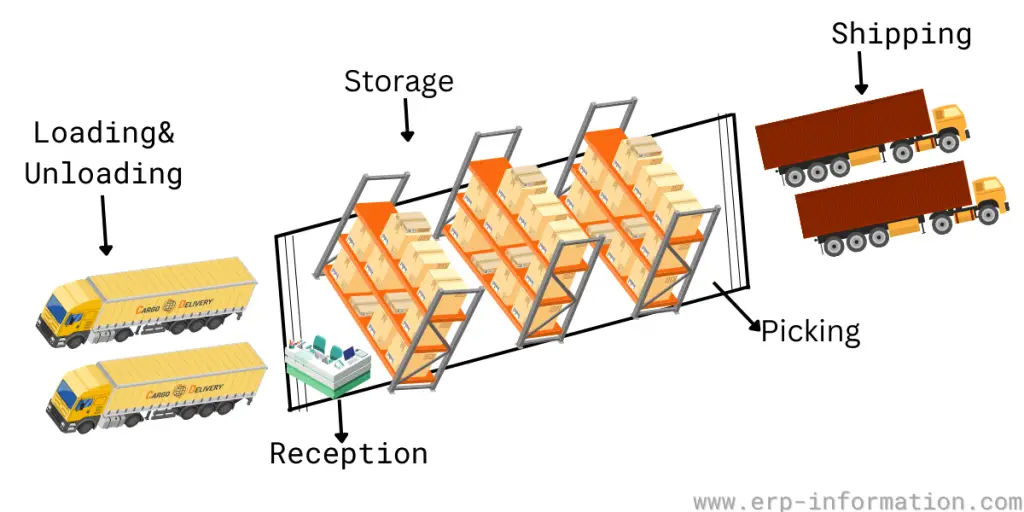

I-Shaped design

The I-shaped warehouse layout is another popular design known as a through-flow design. Here loading and unloading area will be at the beginning of the warehouse, and shipping will be at the end, in the intermediate storage area.

L-shaped design

The L-shaped warehouse layout is a warehouse design that utilizes two ends of the layout for loading/unloading and shipping. The rest of the area is for storage.

Warehouse design and layout ideas tips

When it comes to warehouse design and layout ideas, many considerations must be taken into account. Different types of warehouse designs can be considered according to the size and purpose of the warehouse.

For example, a warehouse may require a simple storage warehouse design or something more complex like a pick-and-pack warehouse or an assembly line warehouse.

Regardless of the warehouse design, here are some tips that can help optimize warehouse design to ensure everything runs smoothly.

1. Determine a suitable warehouse design

The operators should assess the warehouse’s purpose and select an appropriate design. That will help them to maximize warehouse efficiency while avoiding wasting space on unnecessary features.

Warehouse design has much to do with how well the warehouse can function. Therefore, many factors you need to consider when designing a warehouse.

2. Design the warehouse so that products can be easily accessed

The warehouse design should be organized with easy-to-reach storage areas. It is especially important for products that need to be retrieved quickly and without disruption. Use shelves or racks to store small items, and take advantage of other warehouse-specific features such as pallet racks and mezzanines.

3. Use warehouse racking and shelving units

Proper warehouse storage systems can help efficiently store goods and products in an organized manner. That helps streamline inventory management and maximize warehouse efficiency.

4. Ensure there is plenty of space for employees to move around.

The layout must allow plenty of space for employees to move around and access products to facilitate warehouse operations. Therefore, plan the warehouse carefully to ensure sufficient room for employees to carry out all functions without obstacles.

5. Arrange storage areas and aisle spacing

Aisle spacing and warehouse storage areas should be allocated to maximize warehouse efficiency. Additionally, it’s important to assign aisles for specific types of goods or products to streamline warehouse operations.

6. Keep walkways and aisles clear and wide enough for trucks and forklifts.

Design warehouse pathways and aisles to be wide enough for forklifts and trucks to pass through. Also, ensure walkways are clear of objects or crates, helping warehouse operations run more efficiently.

7. Place storage racks close together to minimize wasted space.

The warehouse layout should be designed to minimize wasted space. For example, place storage racks close together so employees can more quickly access warehouse products without trailing a large warehouse floor.

8. Choose suitable equipment

Appropriate warehouse equipment should be chosen based on warehouse activities and size. That helps ensure warehouse operations are running as efficiently as possible.

9. Invest in warehouse floor plan optimization

Optimized floor plans for efficiency can reduce warehouse labor costs and improve productivity.

10. Keep safety in mind

Warehouse safety must also be included in warehouse design considerations. Include appropriate safety features such as fire extinguishers, smoke alarms, lighting, and guardrails.

11. Include security features

Security should be a major consideration when designing a warehouse layout. Install CCTV cameras, alarm systems, and access control systems to protect warehouse staff and inventory.

Installing adequate warehouse security systems is essential to protect goods and products stored within the warehouse. Additionally, warehouse security systems help reduce the risk of theft or accidents within the warehouse.

12. Consider warehouse lighting

Warehouse lighting is a critical factor in warehouse design. Ensure that the warehouse is well-lit to provide workers with good visibility of products. In addition, consider installing motion sensors that supply light only when needed.

13. Determine the loading and unloading area

Designating a specific loading and unloading area in the warehouse is important to ensure that goods can be safely and efficiently moved in and out of the warehouse.

14. Clearly define production zones and workflow areas

The warehouse should be divided into production, storage, and shipping areas. That will help warehouse workers identify where to find goods and optimize operations.

15. Plan for warehouse expansion

As warehouse operations grow, warehouse design must account for potential future expansions. Design warehouse layout so additional storage space can be quickly included without disrupting existing operations.

Overall, warehouse design and layout are key factors in warehouse efficiency and productivity. Careful planning and consideration of warehouse design can help warehouse operators maximize warehouse functionality, safety, and overall performance.

With the right tips for warehouse design, you’ll be able to create a reliable and efficient warehouse environment for your business.

FAQs

What Is a Warehouse Layout?

A warehouse layout refers to the physical arrangement and organization of a warehouse space to optimize efficiency, accessibility, and storage capacity. It involves decisions about where to place storage racks, shelves, workstations, and aisles to ensure that goods can be received, stored, and retrieved in the most efficient and organized manner.

An effective warehouse layout can reduce operational costs, enhance productivity, and streamline the flow of goods, ultimately contributing to the overall success of a warehouse or distribution center.

Why Warehouse Layout Is Important

Warehouse layout is important because it directly impacts operational efficiency and cost-effectiveness. A well-planned layout ensures that items are stored, picked, and shipped with minimal time and effort. It maximizes space utilization, reduces the risk of errors, and enhances safety.

A thoughtfully designed warehouse layout can improve productivity, accelerate order fulfillment, and ultimately lead to cost savings, making it a critical element for any business relying on warehousing and logistics.

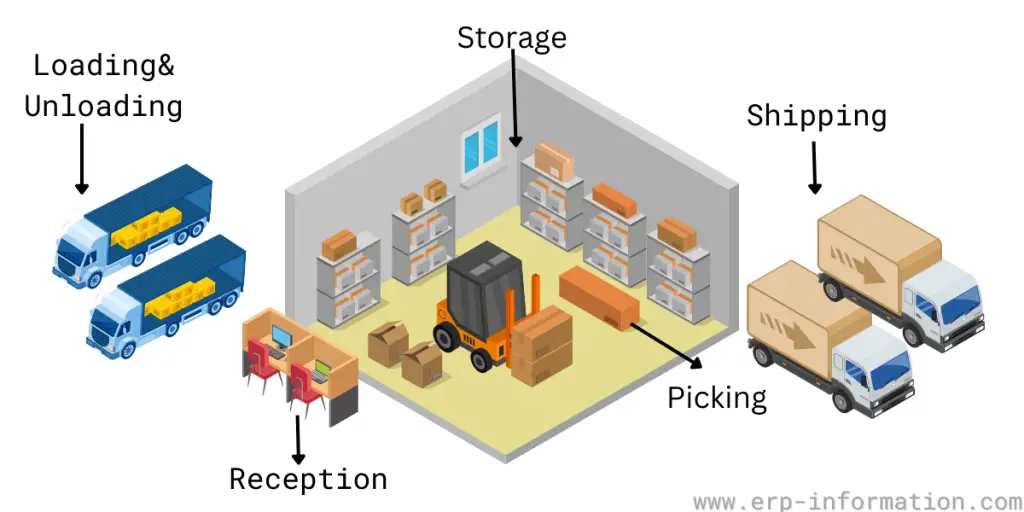

What are the components of the Warehouse?

A warehouse comprises various key components. The primary components include the storage area, which consists of racks, shelves, and bins for organizing products, as well as the loading and unloading docks for receiving and shipping goods.

Material handling equipment like forklifts and conveyors are essential for moving items efficiently. Administrative areas house offices for managing inventory, and there are often designated spaces for quality control and packing.

Conclusion

Warehouse design is an essential part of warehouse operations, and businesses need to consider all the factors and tips mentioned above when designing their warehouse layout. Considering these tips during warehouse design, companies can ensure that the layout is optimized for efficiency and cost-effect.

The post explained warehouse design and layout ideas, types of warehouse layout design, and tips for warehouse design.