It can be tough to know how much to order when it comes to ordering products for your business. You don’t want to run out of products, but you also don’t want too much inventory that takes up space and costs money.

A lot-sizing technique called Period Order Quantity can help you navigate this challenge. This technique considers both supply and demand to determine how much of a particular product to order at regular intervals, depending on the needs and fluctuations of your business.

This blog post will disclose the definition, formula, calculation, and disadvantages of POQ. It also discusses different lot sizing techniques.

Click Here for Supply Chain and Inventory Calculators

Evaluate your fixed order quantity using our Fixed Order Quantity Calculator

By using POQ, you can ensure that you are always ordering the right amount of products for your business, minimizing waste and maximizing efficiency. This will save you time and money in the long run and keep your customers happy.

Definition

Period order quantity is a lot-sizing technique under which the lot size equals the net requirements for a given number of periods. This method predetermines the number of units ordered at regular intervals. This method is employed when the usage rate of raw materials or supplies is stable and predictable.

It is a lot-size technique that orders to cover requirements for a variable number of periods based on order and holding costs instead of a fixed period quantity that uses a standard number of periods.

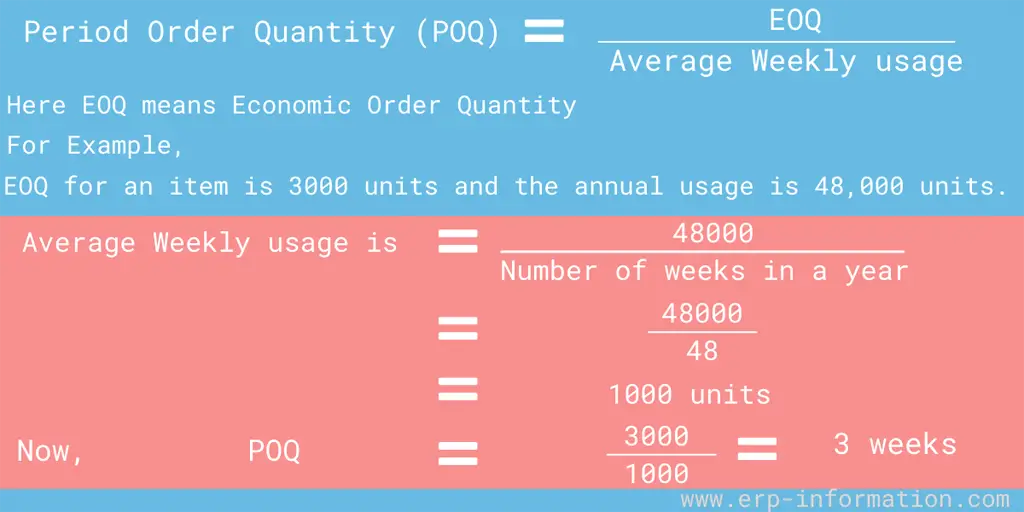

Period Order Quantity Formula and Calculation

When an order is placed, it covers the requirements of 3 weeks.

Disadvantages of Period Order Quantity

The period order quantity method has several drawbacks:

- Large Inventory Investment: Since deliveries are planned to cover extended periods, like a month or a quarter, it can lead to excessive inventory. To reduce this investment, more precise systems like material requirements planning or just-in-time can be used. However, this is less of an issue when unit costs are low.

- Demand Variation: Unexpected increases in demand towards the end of the period can cause stockouts. This can be mitigated by holding safety stock, although this raises inventory costs.

- Demand Termination: Continued deliveries can occur even if demand decreases or stops, due to a lack of tracking. Regular visual inspections by purchasing staff can help address this problem.

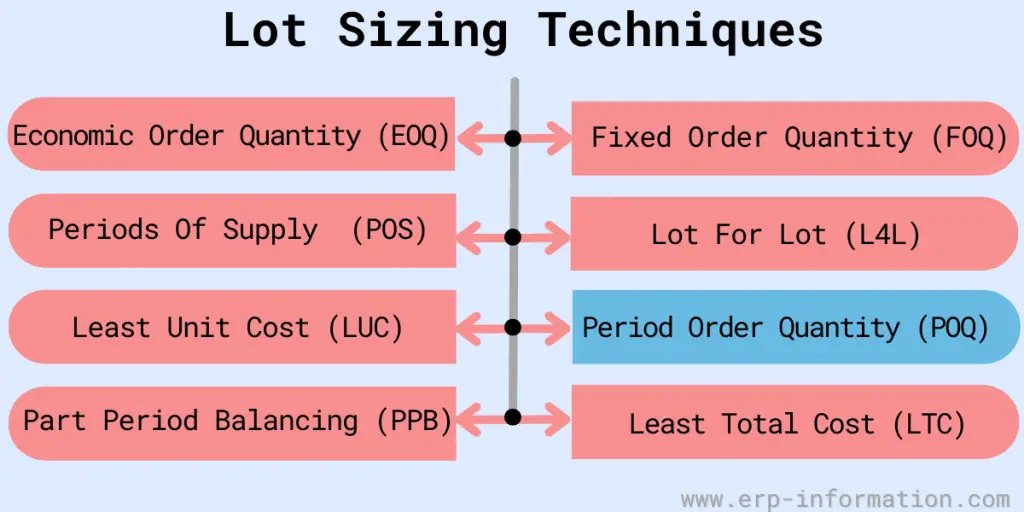

Lot Sizing Techniques

Period order quantity is one of the lot-sizing techniques. Other lot-sizing techniques are

- Fixed Order Quantity (FOQ)

- Economic Order Quantity (EOQ)

- Lot-For-Lot (L4L)

- Periods Of Supply (POS)

- Least Unit Cost (LUC).

- Least Total Cost (LTC)

- Part Period Balancing (PPB)

Choosing the proper lot-sizing technique is crucial because it affects inventory levels, capacity requirements, and ordering costs.

We know that Economic Order Quantity (EOQ) is a significant term in period order quantity.

What is Economic Order Quantity?

Economic order quantity is the absolute quantity an organization should buy to meet its demand while reducing many inventory costs like holding, shortage, and order costs. It is one of the techniques used in inventory management.

The EOQ formula is effective when the company’s demand, holding, and receiving costs stay constant.

The formula for the calculation of Economic Order Quantity is Q = Square Root of [2DS] / H

Here,

- Q = Units of EOQ

- D = Demand in Units (Annual basis)

- S = Order Cost (per purchase)

- H = Holding Cost (per unit, per year)

Click here for the Online Economic Order Quantity (EOQ) Calculator

Advantages of EOQ

- It helps the company to find out its optimal order quantity.

- It allows the company to manage its inventory efficiently.

- It helps reduce inventory costs by finding the exact order quantity in a specific period.

- It helps to avoid stock-outs by determining the reorder point.

- Calculating EOQ allows the company to make good decisions when ordering and managing inventories that increase overall efficiency.

Disadvantages of EOQ

- This concept makes assumptions. It assumes that the demand for the item will be sustained. But in reality, it is not possible. It also takes that the ordering cost for items and holding price per item remain constant for a whole year. However it is not controllable because packing and transportation charges may vary depending on the market situation, and rental may vary for holding items.

- This concept assumes that the inventory will be refilled as soon as it moves to production. But in reality, it does not happen. It takes time to fill out the order. Also, delivery dates vary due to seasonal-related issues.

- Hence there will be a chance of late product supply and sometimes overstock.

FAQs

How does POQ contribute to overall supply chain efficiency?

By optimizing order quantities and timing, POQ helps reduce inventory carrying costs, minimize stockouts, and improve overall inventory turnover rates.

How can businesses determine the optimal POQ for their products?

Businesses can analyze historical demand data, ordering costs, and holding costs to determine the optimal POQ through trial and error or by using inventory management software.

Conclusion

Period order quantity is a lot-sizing technique that orders to cover requirements for a variable number of periods based on order and holding costs.

This technique can help minimize waste and maximize efficiency in your business, saving you time and money in the long run.

However, it is crucial to keep in mind that this technique comes with some disadvantages, such as the potential for increased risk of unavailable items and lack of tracking records for certain goods.

Overall, using POQ outweighs the drawbacks, making it a valuable technique for your business.