It is crucial to understand pegged requirements to maintain an efficient supply chain. Pegged requirements are when you tie a specific sales order or purchase order to a particular order of production.

This blog post will explain pegged requirements and how they work in SAP and supply chain management. Stay tuned for more information!

Pegging in Supply Chain

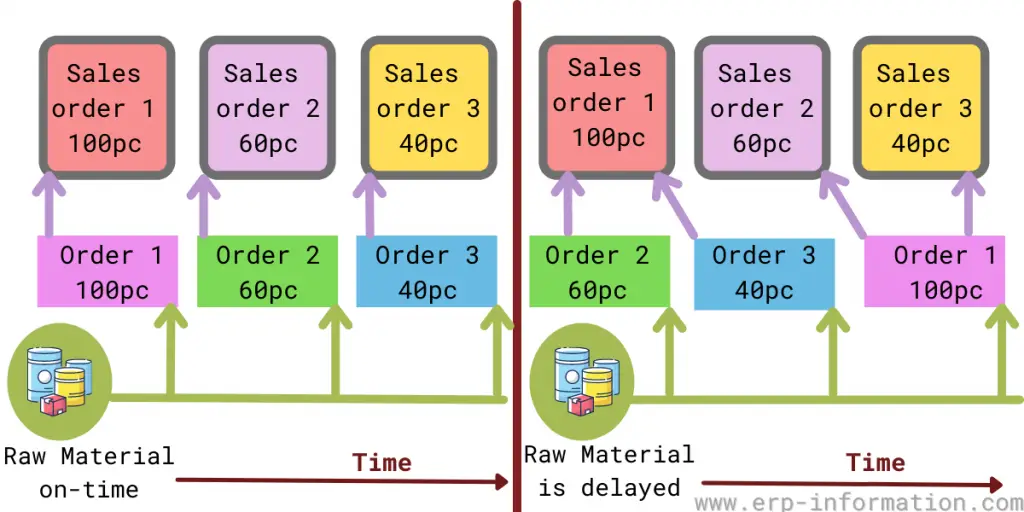

Pegging is the process of tying together two or more orders to create a master and dependent relationship. Pegging can be done with different types of sales and purchase orders.

Pegging allows for better visibility into your supply chain and better planning, forecasting, and scheduling for production management. Therefore, pegged requirements are a very effective tool for the supply chain management.

Pegging allows you to see the future demand for your products and manage your production schedule accordingly.

You can calculate your purchase order finance using the online Purchase order financing calculator

Why is Pegging Needed?

When a firm produces items, it first predicts how much of each product it will sell in the future. Then, based on this estimate, the firm calculates how much of each raw material and component it will require to manufacture the necessary amount of goods.

Forecasting future demand is never an exact science, so businesses frequently must make educated guesses. Companies may utilize “pegged requirements” to help them predict their sales. This means they establish a need for a particular raw material or component based on their higher-level forecast.

To say it in another way, pegged requirements are subject to change based on updates or revisions in higher-level forecasts. This flexibility is crucial for adapting to shifts in market conditions and demand patterns.

Implementing pegging requirements enables companies to align their procurement and production processes more closely with actual demand, improving overall supply chain efficiency and responsiveness.

What is Pegged-Requirement?

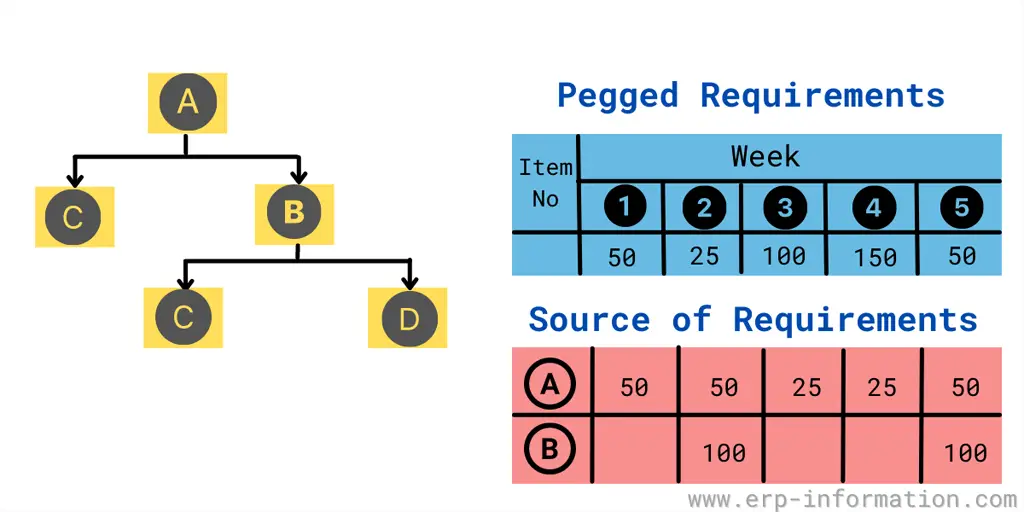

The pegged requirement in production planning is a way to show the next-level parent item (or customer order) as a source of demand. This allows you to track where your materials are going and can help with inventory management, traceability, etc.

[The pegged requirement is a requirement that shows the next level parent item (or customer order) as the source of the demand (i.e., by using the where-used capability from the BOM).]

The following diagram attempts to show the parent and child relationship mentioned above.

FAQs

What is pegging in SAP?

Pegging is a mechanism that allows you to display the relationships between different objects in the SAP system. For example, when creating a sales order, the system automatically pegs that order to the relevant customer account.

Pegging can also display the relationships between materials, production orders, and more. In addition to providing an overview of relationships between objects, pegging can also be used to trace data origins or track changes over time.

For example, if you need to know where a particular material came from, you can use pegging to trace its origins back to the original purchase order.

Similarly, if you need to track how a production order has changed over time, you can use pegging to view a history of all the modifications that have been made.

In short, pegging is a powerful tool that can be used for various purposes in the SAP system.

What are pegged requirements in SAP?

In SAP, Pegged Requirements are called Dependent Requirements. For example, in the Materials Management module (MM), there is a function called “Create dependent requirements” (transaction code MB51).

This transaction allows you to create pegged requirements between two sales orders, between a purchase order and a production order, or between two production orders. The dependent requirement will be created as soon as the first order is released.

What is a pegging report?

A pegging report in manufacturing is a document or tool that informs about the relationships between demand and supply. MRP generates a pegging report.

This report plays a crucial role in developing manufacturing strategies based on the requirements proposed by the Sales and Operations Planning (S&OP) Team.

Conclusion

Pegged requirements offer a strategic approach to anticipating future demand, and aligning specific raw materials or components with higher-level forecasts. This practice serves as a crucial aid in forecasting, recognizing the intricate and uncertain nature of demand prediction.

By implementing pegged requirements, companies enhance their ability to forecast accurately, navigating the complexities of supply and demand dynamics with greater precision.