Bill of capacity is the capacity in different departments required to make a product. In production planning, the bill-of-capacity (BOC) is a document that specifies the maximum amount of work that can be assigned to each resource in a given period.

The capacity bill ensures that resources are not overworked and help plan future production schedules.

This article will discuss the concept of billing of capacity and how it can be used in production planning. We will also explore some of the benefits of using the BOC in production scheduling. Finally, we will provide some examples to help illustrate how the BOC can be used in practice.

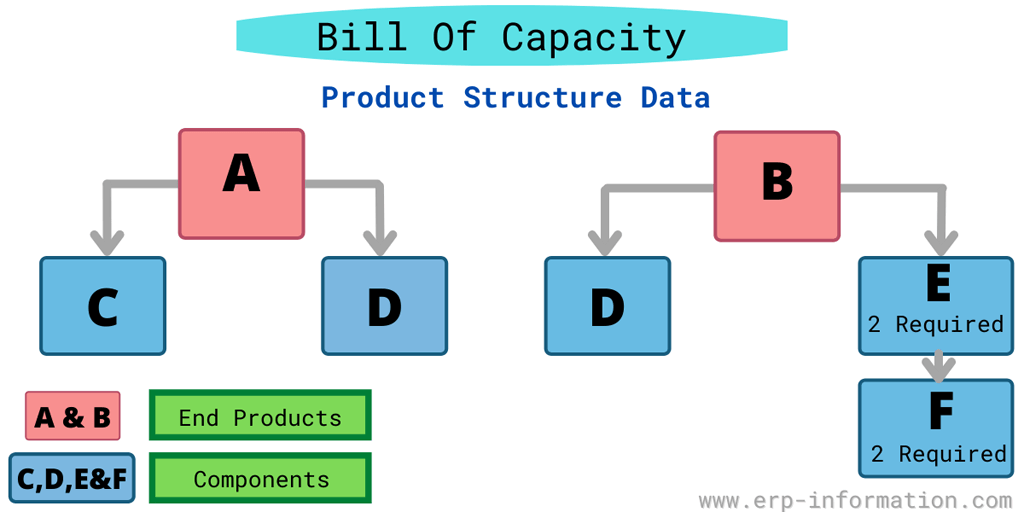

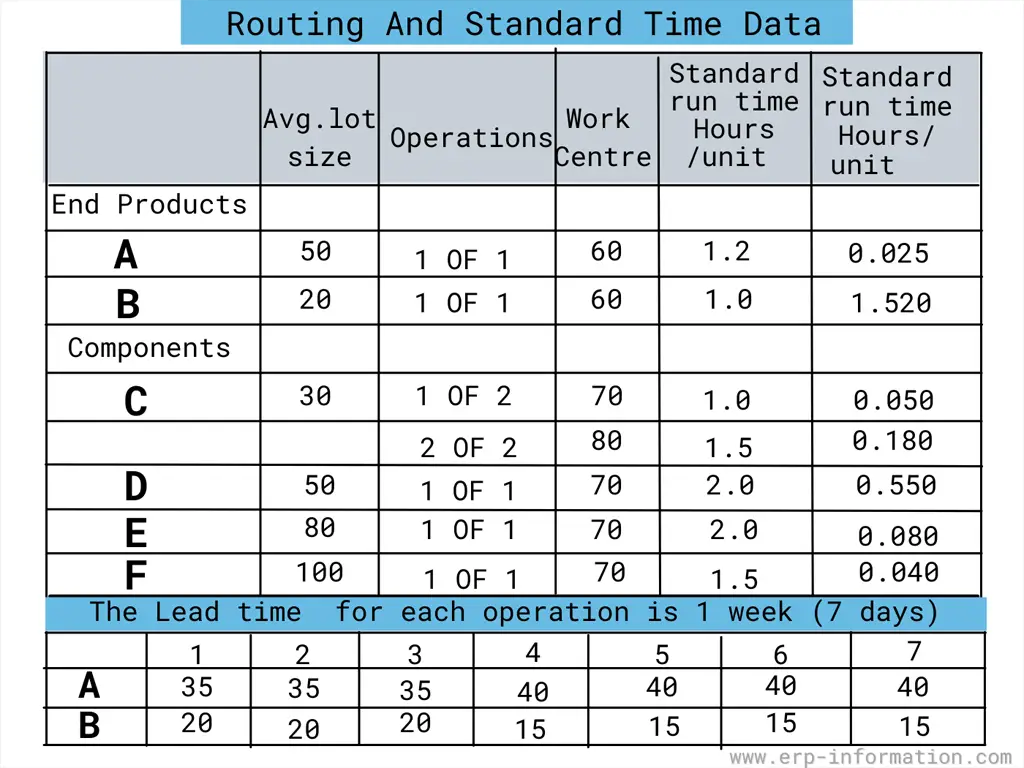

Data required by the bill of capacity method are,

- Bill of material (BOM) (to identify components)

- Bill of capacity, including routing information and capacity requirements in each department

Definition

BOC is a measure of the capacity of the system to handle the demand. It is often expressed as a percentage representing what percent of available resources are used.

The bill of capacity can be calculated in either qualitative or quantitative terms, depending on the organization’s needs.

Qualitative BOC – Asking what production level may be expected under different levels of resource availability, e.g., “If we have 10% more manpower, how much additional output would that potentially produce?”.

Quantitative BOC means calculating how little it takes to produce one unit. Paperwork at every step on how your company works together by adding up raw material costs, lead time, and general administration costs.

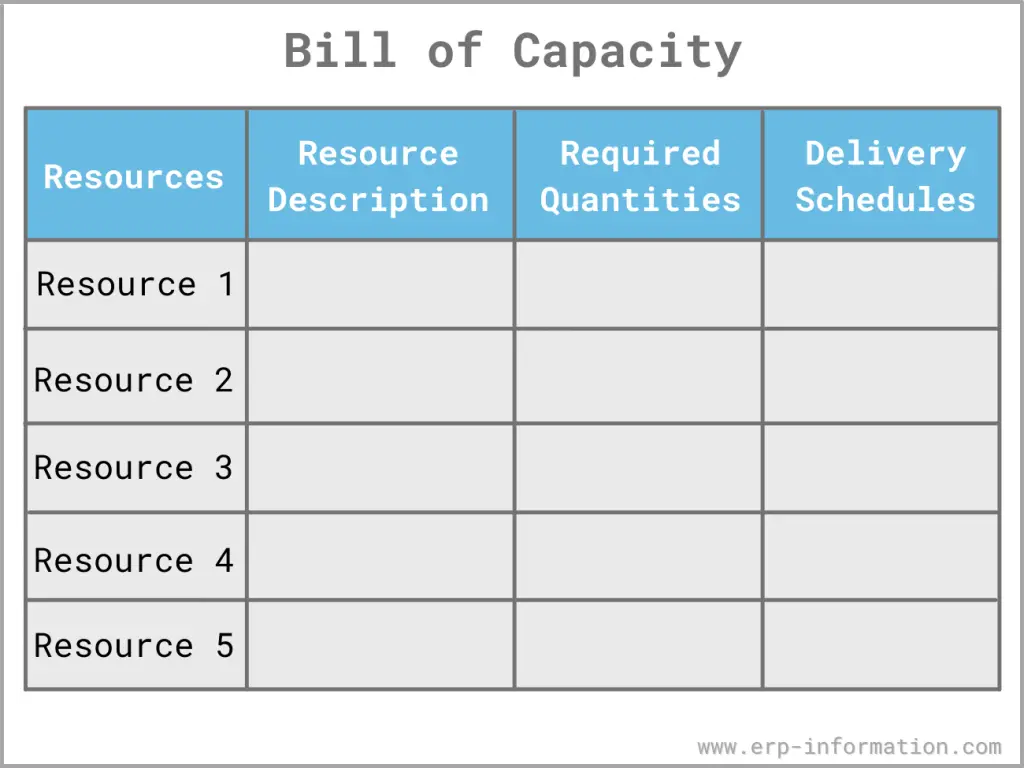

[Below is the sample data form for collecting the capacity bill details.]

Benefits of BOC

The BoC is mainly used in the manufacturing sector that details an inventory of materials, equipment, and labor required to produce one or more products.

It provides insights into what is needed to meet demand, identifies cost-saving opportunities inherent within an upstream process, and highlights subcontracting opportunities which will speed up production timeframes or likely production bottlenecks.

The BoC can also be used as input during the new product design process by identifying materials required for the next production cycle of the current product under development.

This ensures there are no material shortages during the prototyping phases.

BoCs provide valuable insights into material utilization at every level of the supply chain, right down to raw materials.

Example of BoC

Bill-of-capacity is a document that provides an inventory of all resources required for the production process. The document includes a description of each resource, the quantity required, and the delivery schedule.

The bill-of-capacity can be used to create a production plan that outlines the sequence of operations and the time needed to complete each step. It can also calculate the total cost of producing a particular item, track inventory levels, and determine when new stock is needed.

One typical example of a bill-of-capacity is a materials requirement planning (MRP) system. In an MRP system, the bill-of-capacity lists all the materials needed to make a product and the quantities of each material required. Then, the MRP system uses this information to generate purchase orders for the necessary materials.

Conclusion

Capacity bill calculations are used as guidelines for ordering parts and materials from suppliers. They also help allocate labor resources between projects.

The calculation can be done by weight or volume, depending on what unit you use in your production line.

The article above explored how can use capacity bills in production planning. We hope you have found this information applicable to your work and look forward to serving you with the information you need again!

Get more definitions about the bill of capacity and other ERP-related terms here.