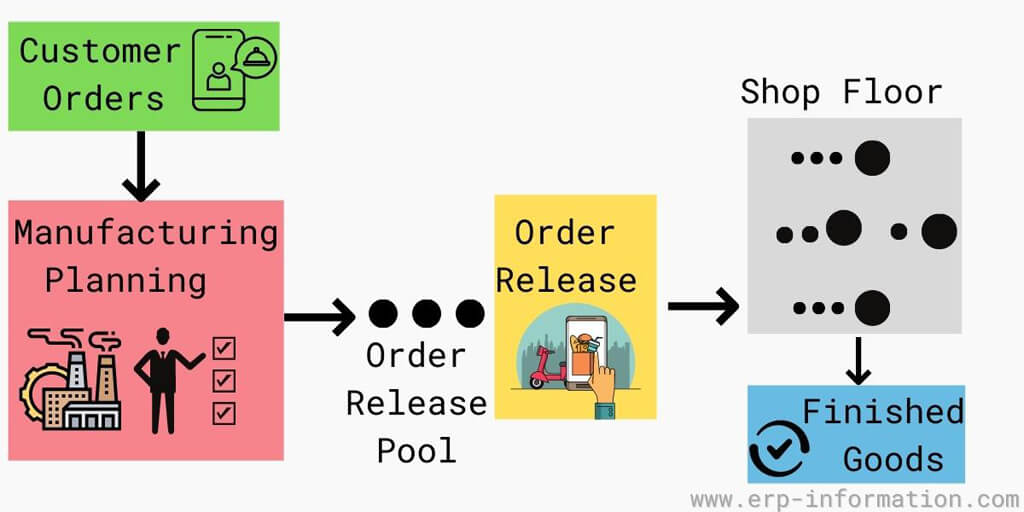

An order release is like the official document that brings about the release orders of those items ordered.

The supply letter gives the authorization to host the release of shipping and delivery of finished products to the customers.

Order release is releasing goods from a supplier to a customer. The order release date is when the goods are made available. This can be done in two ways: by issuing an invoice to the customer or physically shipping the goods. The order release date is the ship date or delivery date.

Order release process

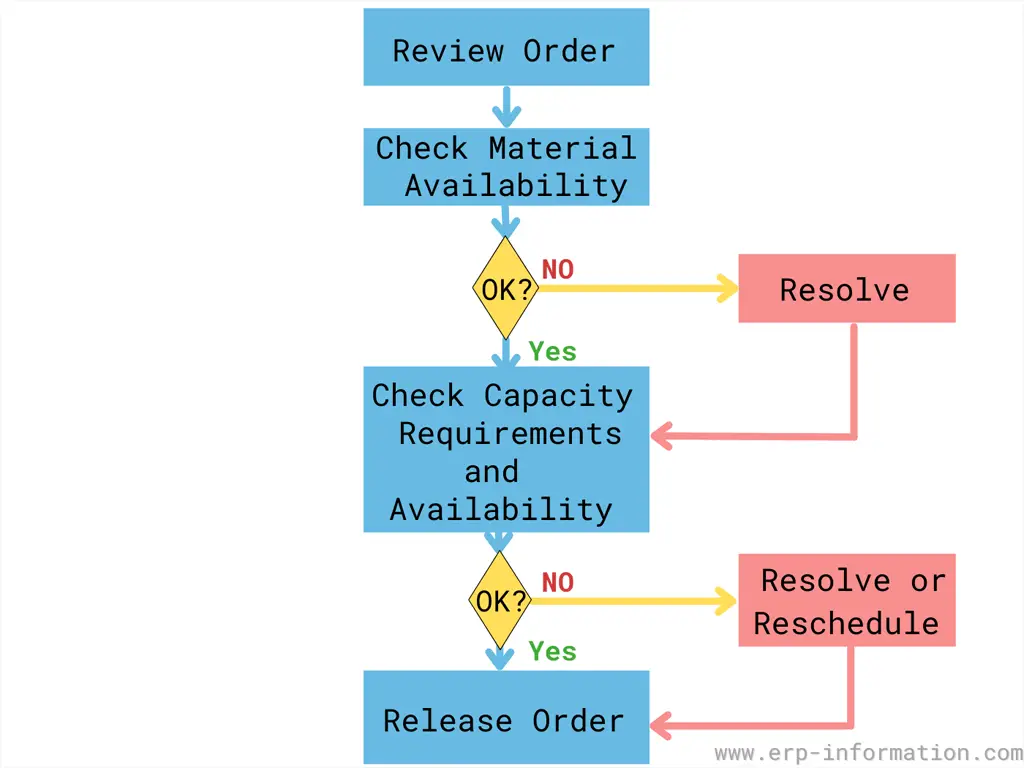

The below image shows the process of order release in the form of a flow chart.

- The first step is to review the order. Then check the available materials required to produce the product of the ordered quantity.

- Check the capacity requirements and available production capacity if sufficient materials are available. On the other hand, if you find a shortage of materials, then solve that problem and check capacity requirements.

- Once you check the availability of the capacity requirement, you can release the order for further processing.

What is an order release form?

An order release form includes the details of the dealer and all other details regarding the material being released by the storage for production.

It is like a formal order being released directed toward the warehouse to begin the production-related activities. It is the power to convert the customer orders into production orders against those customer orders and start the processing activities.

Many restrictions are lifted once an order release has been issued.

- A confirmation is released about the order at hand. A particular customer order gets confirmed once a release order has been put out. This order then starts the processing of the demanded units. Raw materials are ordered to be released, laborers are appointed to this job, and the production procedure finally begins.

- Shop floor papers are printed after the order release of a customer order. Without the release order, the design and architecture preparation is also halted.

- Movements of prepared goods or the end products cannot be ordered without a release order. That also means release order shipping efficiently delivers the set and ready items after completion. So, a release order is being issued to start with the processing, follow the entire production process, and finally, when the fulfillment is over, ship and deliver the orders to the customers.

An order release must be well-timed. If not, a mix-up can originate that might halt the production, and the company might also suffer losses.

Therefore timing a release order exactly when the firm is ready to begin production is crucial.

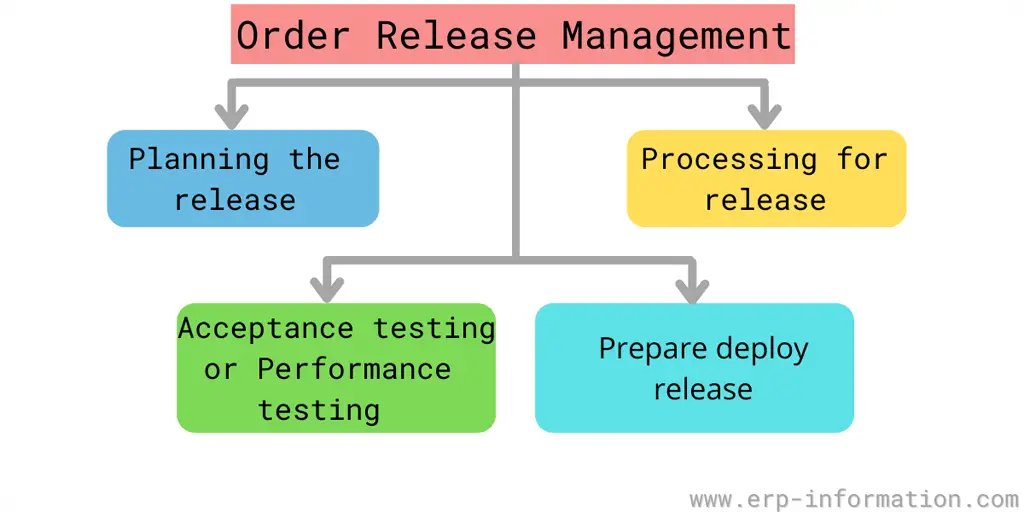

Order release management

An efficient order release management is essential for any manufacturing firm. Structuring an economically sound order release management plan allows the firm to withstand instability and perform well in the face of adversity.

Planning the release

A proper release plan is the best idea to begin. Structure your release plan with details like the timeline, quantity to be released, units to be produced, and delivery dates.

Such a release plan will also allow your employees to get the entire project within a glance; thus, the scope for mistakes is found to decrease.

Processing for release

It is the exact step where the production process begins, and the entire procedure slowly builds up towards a timely release of high-quality finished goods.

Acceptance testing or performance testing

At this stage, the end-users get to test the final product. That is also a test for the product’s function in the real world.

Often the presence of bugs and issues are fixed at this stage, for which it might again go back to a previous step to get cleared of its technical problems.

Hence this is an iterative step that involves many steps in cycles.

Prepare and deploy the release.

Preparing and deploying the release step includes changes in how your product works. COmpanies might educate employees and end-users about using the product during this phase. A sound release management system is essential for developing new product versions. You will need to adapt this system based on what you find when it comes time to release new versions of your product.

Conclusion

Order release is the process of processing an order for a customer. Some companies do this with sales, and some do it with fulfillment. The order form should include information about what was ordered, how it will be shipped, and any other details that might affect delivery.

Order release management: An organization’s ability to fulfill orders efficiently depends largely on its capacity to manage this process well through effective inventory control systems, efficient scheduling practices, and accurate forecasting models.