In today’s competitive world, ensuring your products have zero defects is essential for success. Zero defects in quality management isn’t just a dream; it’s a goal you can reach with the right approach.

Zero defects in quality management is a company plan to ensure that all products leaving their facility are defect-free. Companies can do this through comprehensive planning and vigilant employees constantly looking for errors.

Implementing zero defects can be challenging, but the benefits make it worthwhile.

In this blog post, we’ll explain what zero defects mean, its key principles, and the benefits it can bring to your business. We’ll also discuss some challenges and give you practical tips to help you achieve zero defects in your operations.

Definition

Zero defects is a quality management term that means products and services are released without non-conformities.

The zero defect means there are no defects in a given product. This is especially important when dealing with food and other regularly consuming items.

To achieve this, companies must have processes that prevent defects from happening in the first place. There are many benefits to achieving zero defects, including improved customer satisfaction, reduced rework, and increased efficiency.

Achieving zero defects can be challenging, but it’s worth the effort to ensure that the quality standards are well-maintained and the defects are reduced to the possible extent.

There are many ways to achieve zero-defect output. For example, you can use statistical process control charts to identify and eliminate the causes of variation in your process. You can also use quality tools such as cause and effect diagrams, check sheets, Pareto charts, and FMEA (failure mode and effects analysis) to identify and eliminate defects in your product.

Zero Defect Six Sigma

Adopting zero defects means committing to doing things right from the start. This approach targets the elimination of flaws, enhances the quality of products or services, and minimizes costs related to inefficiencies and waste.

While achieving zero defects in large-scale or complex manufacturing is not technically feasible, Six Sigma defines zero defects as having only 3.4 defects per million opportunities (DPMO), accounting for a 1.5-sigma process shift.

Essentially, zero defects should be viewed as a goal that drives continuous improvement and quality enhancement in manufacturing or development processes. Although absolute perfection may be out of reach, the pursuit of this goal ensures that quality and performance are optimized to meet even the most demanding standards.

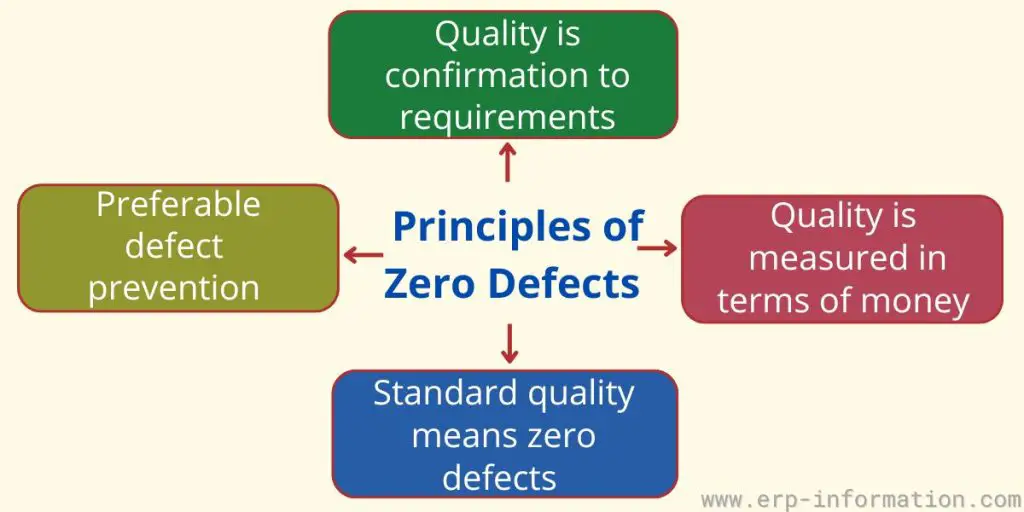

Four Important Principles of Zero Defects in Quality Management

- Quality is important to ensure that all the important factors of production are taken care of, making way for good processes and procedures.

- Quality must be given equal importance and must be set right. It doesn’t make sense that the company starts with its production and then tries to determine the quality standards. The number of defects detected must be minimal. If not, it will cost a huge amount to the business to set everything right.

- Quality is money. To compare the data, the business must ascertain its waste, production, and profits in monetary terms.

- The company must keep zero defects as its target and try to reach a state of perfection though it is practically impossible to attain such a state.

Zero Defect Manufacturing Implementation

Incorporating advanced technologies such as Artificial Intelligence (AI) and Machine Learning (ML) enables organizations to significantly enhance product quality and minimize, if not eliminate, defects. The implementation process can be categorized into two key areas: Detection and Prevention.

Detection: This phase involves assigning responsibility for identifying, reviewing, and addressing defects. By utilizing AI and ML, organizations can efficiently detect anomalies and execute repairs to rectify issues promptly.

Prevention: This phase focuses on preemptively identifying potential process variations that could lead to defects. Responsible personnel leverages AI and ML to foresee and mitigate deviations, ensuring that unintended errors are prevented before they occur.

How do We Adopt Zero Defects?

There are no proven instructions to achieve zero defects. Following are the few guidelines that need to be followed to adopt zero defects.

Set clear quality standards

Define what ‘perfect’ looks like for your product or service. These standards act as your guiding stars, outlining precisely what you aim to achieve in terms of quality.

Learn Poka-yoke

It was invented by Shigeo Shingo, a Japanese industrial engineer. It is a fascinating concept that revolves around preventing mistakes before they happen. The term is derived from Japanese, meaning “prevent inadvertent mistakes.” Embracing poka-yoke (pronounced “POH-kay YOH-kay”) involves designing processes or systems in a way that makes errors nearly impossible.

Identify process defects

Pinpoint where potential errors or defects might occur in your processes. That involves closely examining each step to understand weak points or areas prone to mistakes. Identify the changes to be done in the process by recognizing the proper way to do things.

Establish preventive measures

You know, “prevention is better than cure.” Therefore, Once you’ve identified potential areas for defects, put preventive measures in place. These can range from improved procedures, better training, enhanced technologies, or even redesigning processes to eliminate the root causes of defects.

Understand the customers’ needs

Understand customers’ requirements in terms of quality. It involves a deep exploration into what customers truly value and expect from the products or services they invest in. Then, try to meet the customers’ expectations.

Monitor quality

Implement systems to continuously monitor quality at every stage of production or service delivery. Create a qualified team for quality improvement. Regular checks and assessments ensure that you catch any deviations from the set standards early on.

Educate employees on quality

It’s crucial to educate and empower your employees about the importance of quality. Provide training that not only highlights the standards but also equips them with the skills and knowledge to maintain those standards consistently. Encourage the employees to get quality products by motivating, pledging, challenging, telling the importance of teamwork, and giving rewards.

Motivate continuous improvement

Encourage a culture where improvement is a constant pursuit. Motivate employees to suggest enhancements, be it small tweaks or significant innovations, to elevate quality standards continually.

Benefits

It benefits the organization in many ways.

Aligns process

One of the most significant advantages of this concept is that it tries to align all the required processes precisely.

So, it ensures that the firm does not suffer significant damage or loss and thus saves costs. It also leads to waste reduction as it is constantly monitored and controlled.

Enhances workers’ morale

Usually, workers think that some minor mistakes will happen while working. However, the zero-defect concept changes this mindset of the workers and encourages them to work without defects. That increases workers’ morale.

Improves customer relationship

Better quality means delighted customers and repeat customers. End of the day, it translates to long-term customer relationships and more profits for the company.

However, the business must be careful that the strict environment created to ensure zero defects does not lead to reduced morale of its employees.

Constant improvement must be encouraged, which will sum up living the goal of zero defects.

Disadvantages

Technically it is difficult to achieve zero defects. There will be a chance of a negative impact on performance because of the time and resources committed to zero defects.

It may negatively affect the whole supply chain when the other manufacturer has a different definition of zero defect.

Zero Defect Examples

One of the most famous zero defects examples comes from Henry Ford, who says, “Quality is Job 1.” Ford implemented rigorous quality control measures at his factories to produce cars free of defects. This helped him gain a reputation for producing high-quality products and staying ahead of his competition.

Other zero defects examples include Japanese companies such as Toyota and Honda, known for their high-quality standards and attention to detail. These companies have become world leaders in manufacturing because they produce products that meet or exceed the expectations of their customers.

FAQs

What is Zero Quality Control (ZQC)?

ZQC is a Japanese philosophy and management principle that aims to eliminate waste in the production process. In addition, the goal is to achieve “zero defects” or products free of errors and meet customer requirements.

ZQC has been credited with helping to make the Japanese manufacturing industry one of the most efficient in the world. Toyota, in particular, is well-known for its implementation of Zero Quality Control, which has helped it become the largest automaker in the world.

What is a Zero Defect Plan?

Zero Defect Plan, also known as the zero-defect program, is an organizational philosophy that aims to reduce the number of defects in new products or processes.

In other words, this is a commitment from the company to its customers that all goods will reach them without defects or “defectives.”

While it has widely been applied in many industries, some aspects of the plan are controversial. For example, while some contend that quality by design is vital for prevention work, others assert that zero-defect calls for new designs that make it impossible to foresee premature faults beforehand.

Furthermore, some indications are related to its implementation difficulty and lack of traceability. Due to these reasons, many companies abandon zero-defect strategies since their results do not meet expectations.

What is zero-defect manufacturing?

Zero-defect manufacturing is a quality philosophy that seeks to eliminate all product defects and is usually aimed at reducing the amount of rework or scrap that results from producing defective products.

The goal is to have every product manufactured to meet the customer’s quality requirements without defects. This generally requires a rigorous process of inspection and testing to catch any problems before they reach the customer.

It can also require steps such as Design for Manufacturing (DFM) and Design for Assembly (DFA), making it easier and cheaper to produce high-quality products.

How to do the Zero Defect analysis?

Zero defect analysis is a quality assurance methodology applied to any process to identify and eliminate defects. It relies on breaking down the cycle into smaller steps to examine each step for potential faults.

Conclusion

Quality management is a process of reducing the number of defective products. Achieving zero defects in quality management requires continuous improvement, changes, and commitment from all levels of an organization.

Organizations should better understand their customers’ needs to design processes that produce better-quality goods or services.

It’s also essential to have systems that help identify problems before they become severe enough to result in damages or consumer complaints. This way, organizations will avoid costly errors that could jeopardize reputation and profitability over time.