Known for their integral role in the globally renowned “Toyota Production System” (TPS), andon cords have become a household name in factories across the globe.

Curious about Andon cords? What is their purpose?

Read our article to discover how these ingenious devices ensure smooth operations, maintain quality, and empower workers to address any issues on the production line.

This blog post will explore everything you need to know about Andon cords, including their history, different types, industry use, and role in the “Toyota Production System.”

Definition

The Andon cord is a physical cord or button used in many automotive and manufacturing plants to alert supervisors and management of production problems or quality issues.

The cord is typically pulled or the button activated by workers on the factory floor when they observe a problem that needs attention.

Toyota invented the Andon Cord as part of its “Toyota Production System.”

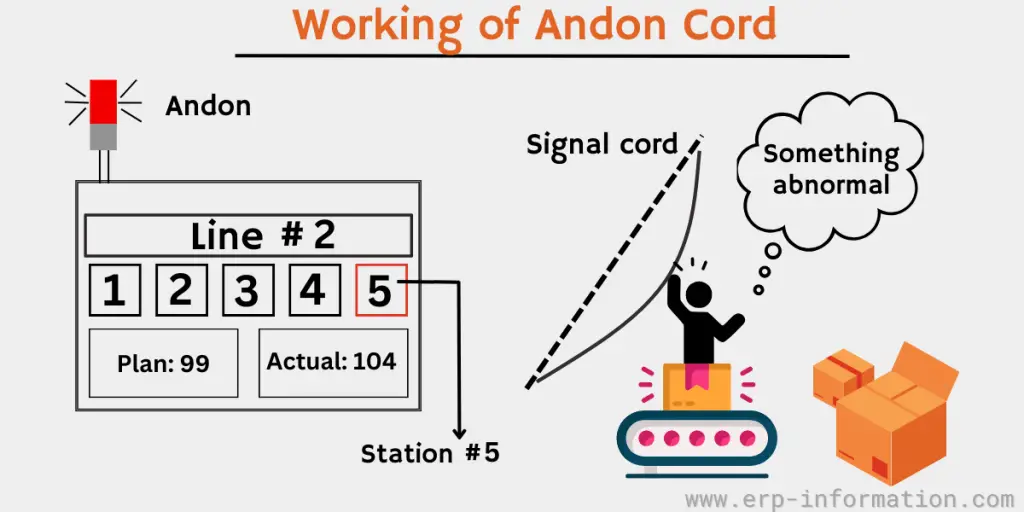

How does it work?

It is a physical or digital cord that triggers an immediate stop of work at a station. In addition, it signals quality or safety issues so that a supervisor can address them.

In practice, when the cord is pulled by a worker, it automatically alerts the supervisor, enabling them to quickly address the problem at hand. This empowers workers to report issues by pulling the cord, allowing them to resume work once the matter has been resolved.

Benefits of Using Andon Cord

- Improved quality: It helps identify and address quality problems before they cause further damage or waste.

- Increased productivity: It can reduce downtime by allowing workers to stop production immediately if they see a problem.

- Improved safety: It can help prevent accidents and injuries by allowing workers to stop production if they see a safety hazard.

- Increased employee engagement: It empowers workers to take ownership of their work and helps improve the workplace’s quality and safety.

History

Its history dates back to the early 1900s when ‘Sakichi Toyoda’ invented the first version of the device. His invention was designed to improve communication and safety in factories’ production lines.

The original cord consisted of a string or wire that ran throughout the factory. Toyota Employees could pull on the string or wire to signal for help.

The modern version is typically a button or switch that can be activated by anyone who needs help. When pressed, the cord sends a signal to a central location, typically a control room or office. It can signal via an alarm, light, or visual cue.

Jidoka Principle

The Jidoka principle is a key part of the Toyota Production System and helps to ensure quality in the production process.

Jidoka indicates “automation with a human touch” and refers to using machines to detect defects and stop production when a problem is detected. This allows workers to fix the problem immediately and prevents defective products from being produced.

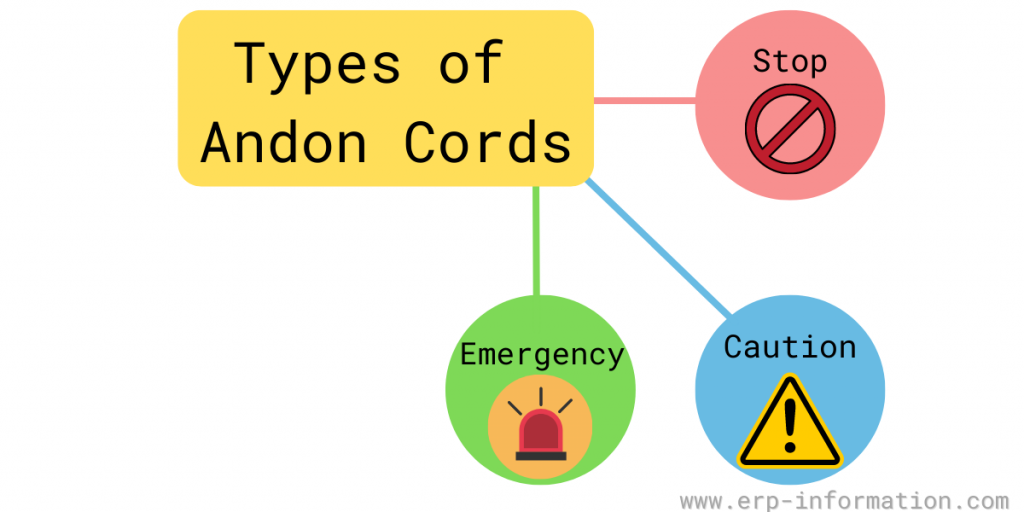

Types

There are three types: stop, caution, and emergency.

- Stop cords are used to stop the assembly line immediately.

- Caution cords warn that something is wrong or about to happen.

- Emergency cords are used to stop the machine or process it immediately.

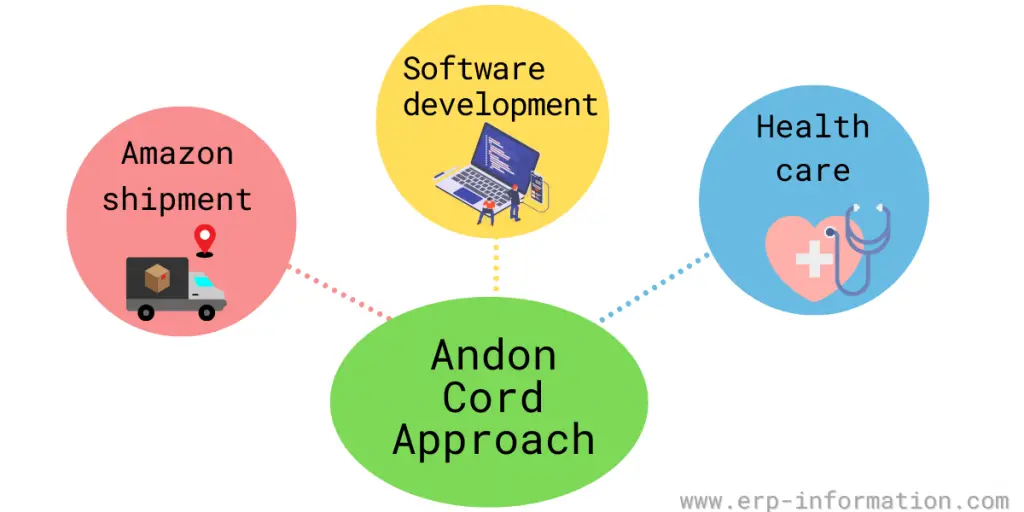

Andon Cord Approach Examples

Over time, these cords have evolved with far superior technology. For example, Toyota started replacing analog cords with modern Toyota cord systems such as electronic signaling devices and push buttons.

However, the concept of it has become famous in many management systems throughout the world.

The Andon cord approach used in,

- Amazon shipment

- Software development

- Healthcare, etc

How Does the Andon Cord Approach Work?

1. Amazon shipment

Amazon finds the Andon cord concept as a practical approach to minimizing the faults in its customer service and improving quality.

- In the Amazon Andon cord process, the Amazon service representative gets notified by the customer that some issue is present in the received product from Amazon.

- If the representative finds this issue is repeating, he can pull the cord. Pulling the cord means he notifies the issue to the supervisor. After getting an alert from the representative, the supervisor adjusts the website to stop distributing that product until the problem is resolved.

- Then, the supervisor creates the Andon cord ticket and informs the product distributor about the issue by sending an email that includes the product ASIN and details about the product defect.

- If the distributor fails to solve the problem, the website will remove that product from its product list.

- Implementing this process helps pause the sales and deliveries before the defect reaches more consumers.

2. Software development

Pull the Andon cord analogy is also used in software development

The virtual Andon cord Kanban tool allows team members to signal when they need help in software development.

Team members place cards on a board to indicate their work. When they need help, they move the card to the “help” column, and the team leader or someone from the team who is available picks up the card and helps with the work.

The virtual Andon cord allows team members to signal for help without leaving their desks or stopping what they are doing. That helps ensure that everyone can get the help they need without interrupting their work.

3. Healthcare

The Andon cord concept has also been adapted for use in healthcare. In healthcare, This is a tool that can be used to help in various situations.

For example, it can signal for help when a patient needs a nurse, doctor, or medical assistance. The cord can also signal for use when a staff member needs assistance.

The cord can also signal help when a staff member needs a break.

Why are Andon Cords Essential?

- Give employees a voice to raise concerns about quality or safety issues.

- Encourage employees to take ownership of the quality of the products they produce.

- Help supervisors quickly identify and address quality or safety issues.

- Stopping work allows the issue to be addressed quickly and prevents further problems.

- It can be used as a tool to prevent errors and helps continuously improve any process.

FAQs

What does the word Andon mean?

The term “Andon” comes from the Japanese word for the paper lantern.

The Japanese call their form of quality control the “Andon” system. Andon means “guiding light,” which they use to acknowledge that jobs are done without interruption.

What is Andon Cord Ticket?

It is a document used to track and communicate issues with a product. The ticket includes information about the product defect, such as the product ASIN and details about the problem. The ticket also provides information about the distributor responsible for fixing the problem.

What is Amazon Andon Cord?

Amazon recognized the need for an effective safety measure and adopted Andon Cords in 2012, giving support agents ultimate control over product quality. With one pull of the cord, a warning or buy box suspension is issued if any risk to customers is detected – even from something as small as a single nasty review.

How is the Andon Cord used in Amazon?

When an Amazon representative gets a call from any customer with an issue or defect in a product, the representative uses “ pull the cord.” That alerts the distribution chain, and they will remove all the products from distribution and not put them back for sale until the problem is solved. In this way, Amazon prevented many customer service issues.

Conclusion

Andon cords are essential in any manufacturing line or production line. They allow employees to raise concerns about quality or safety issues and help supervisors quickly identify and address problems.

Many organizations implemented its concept to prevent errors and help continuously improve any process. For example, Amazon has implemented its idea in its customer service to minimize faults and improve quality.

Furthermore, the virtual Andon cord Kanban tool enables software development team members to request assistance without disrupting their workflow. As a result, they play a crucial role in any quality management system.