If you’re looking for an efficient and easy way to improve your manufacturing process, consider using andon lights.

They are signal lights that notify workers of a problem or issue in the production line. Unfortunately, many different types and brands of andon lights are available on the market, so deciding which is right for your business can be challenging.

This blog post will provide an overview of the different types of andon lights available and a list of vendors that sell these products. We’ll also discuss the benefits of using them in your manufacturing process and outline tips for choosing the right product for your needs.

What are andon lights, and what do they do?

Andon lights are a type of signal light that notify workers when there are problems with the production line.

For example, these can indicate when machines need to be stopped or restarted because they’re experiencing issues like quality-related problems and safety hazards in their tasks – which is vital for lean manufacturing strategies, so everything runs smoothly without any hiccups!

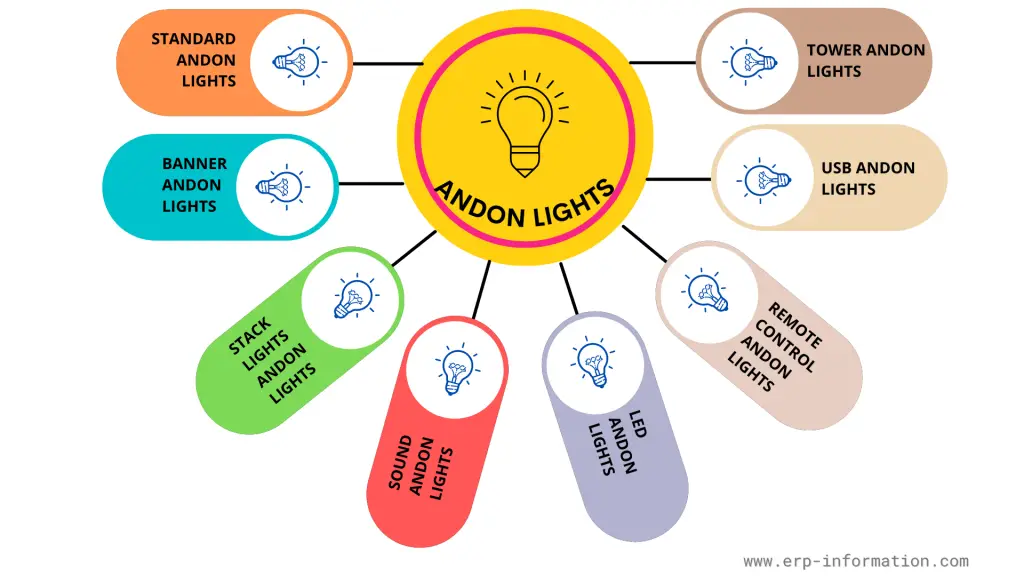

The different types of andon lights

Standard andon lights

Standard andon lights are the most basic type of signal light. These lights typically contain a red, yellow, and green light controlled by a switch.

The red light indicates a problem or issue that needs to be addressed, the yellow light indicates when the machine needs to be stopped or restarted, and the green light indicates when the machine is running smoothly.

Banner andon lights

These are signal light types that are typically used in assembly lines. These lights consist of a banner that is hung from the ceiling and has a light that is controlled by a switch.

The banner andon lights can indicate when a machine needs to be stopped or restarted, when there is an issue with the quality of the product, or when there is a safety hazard.

In many cases, the banner andon lights will also have an audible alarm that will sound when the light is activated.

That can help notify workers in the area that an issue needs to be addressed. These are an essential part of any assembly line, and they can help improve the line’s efficiency while also ensuring the safety of the workers.

Stack lights andon lights

These are signal light types that are typically used in assembly lines. These lights consist of a stack of three lights controlled by a switch. The switch controls the sequence of the lights, and each light represents a different stage in the assembly process.

Stack lights andon lights are essential to many assembly lines, as they help keep the line moving smoothly and safely.

Sound andon lights

The sound of an alarm can be a jarring experience, especially when accompanied by flashing lights. But for workers in a factory or other industrial setting, these signal lights are essential for their job.

Sound andon lights are designed to attract attention and alert workers to a problem or issue in the production line. Sometimes, the alarm may be sounded by a human operator, but it is often automated. These alarms can be lifesavers, helping to prevent accidents and mistakes.

In a busy factory setting, they can also help keep the work flowing smoothly by drawing attention to potential problems before they cause a stoppage in production.

LED andon lights

One of the key benefits of LED andon lights is their energy efficiency. These lights use less power than traditional incandescent bulbs, which can help to reduce energy costs.

In addition, LED lights have a longer lifespan than traditional bulbs, meaning they need to be replaced less often. As a result, these can provide both financial and environmental benefits.

Remote control andon lights

These offer the same benefits as traditional andon lights, but with the added convenience of being able to be activated from a distance. This can be useful when it is not possible or practical to physically pull the Andon cord, such as when an emergency arises outside of regular working hours.

Remote control andon lights can also be programmed to activate in certain situations, such as when a fire alarm is triggered automatically. So whether you are looking for a way to improve communication in your factory or want to add extra safety to your workplace, these may be the perfect solution.

USB andon lights

These are a type of signal lights that a USB port can power.

These lights are commonly used in manufacturing facilities to indicate the status of a process or machine. For example, a green light may indicate that a machine is running smoothly, while a red light may show an issue that needs to be addressed.

They offer several advantages over traditional signal lights. They are less expensive to operate and maintain and can be easily added to existing machines and equipment. In addition, USB lights are more versatile than traditional signal lights, making them an ideal solution for various applications.

Andon tower light

Tower lights are a type of signal light typically used in assembly lines. These lights consist of a tall tower with a light on top controlled by a switch.

The purpose of the light is to signal when an issue occurs so that it can be resolved quickly. For example, the light will indicate an issue if a part is missing from the assembly line. In this way, tower lights help to ensure that problems are quickly identified and addressed, allowing the assembly line to run smoothly.

Many different types of tower lights are available on the market, each with its own features. However, all tower lights share the same primary function: to help keep the assembly line running smoothly.

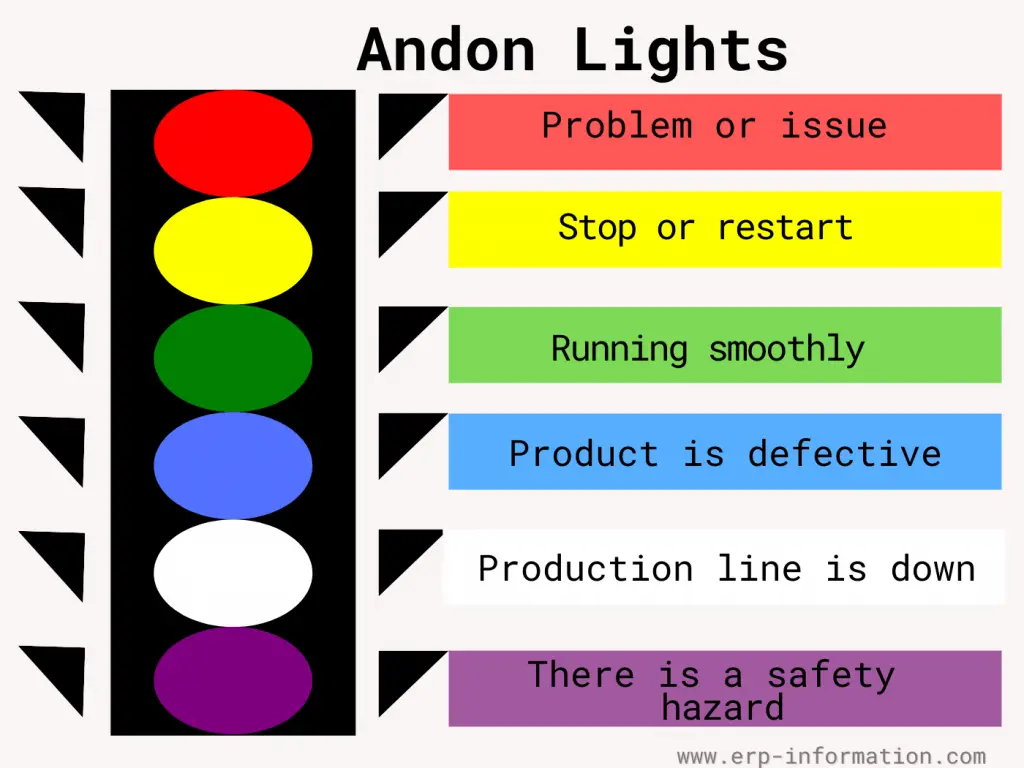

The different colors of andon lights and their meanings

| Colors | Meaning of colors |

| Red | Indicates when there is a problem or issue that needs to be addressed |

| Yellow | Indicates when the machine needs to be stopped or restarted |

| Green | Shows when the machine is running smoothly |

| Blue | This means when the product is defective |

| White | This means when the production line is down |

| Purple | Displays when there is a safety hazard |

The benefits of using andon lights in your manufacturing process

They are an essential part of lean manufacturing and can help improve your production process’s efficiency.

- Reduce downtime

- Improve communication

- Increase safety

- Enhance quality control

- Boost productivity

If you are looking for a way to improve the efficiency of your manufacturing process, then andon lights may be the solution for you. Various vendors sell andon lights, so be sure to research to find the best option for your needs.

How to choose the right andon lights for your needs?

When choosing it, there are a few factors that you will need to consider, such as:

- Type of manufacturing process

- The size of the production line

- The budget

- The level of customization

Once you have considered these factors, you can narrow down your options and choose the best andon light for your needs.

Vendors that sell andon lights

1. LUBAN

LUBAN companies are adopting high-performance LED chips. These andon lights are typically used as Automated machinery status indicator lights and safety warning lights in factories and industries.

2. SICK AG

They are one of the resourceful suppliers of industrial visual and audible alarm products for factory floor automation and production. Major products are Tower lights, signal lights, buzzers, alarms, etc.

3. Signaworks

Signaworks has several series of andon lights and gives technical and application support. Examples include industrial warning lights, Production cycle timers, and Downtime Monitor tower lights.

4. Schneider electric

Schneider electric producer of tower lights are available, pre-wired, pre-assembled, modular constructions with different technologies, colors, and shapes.

5. Andont 3

To help Improve Productivity and save time, it provides 3 Stack LED Tower Lights in the workstation and warehouse.

This is by no means an exhaustive list of vendors that sell andon lights, but it should give you a good starting point in your search.

FAQs

How do Andon lights contribute to quality control and defect prevention in manufacturing?

Andon lights are instrumental in maintaining quality control by immediately alerting workers to any issues or defects. This prompt notification allows for quick corrective actions, preventing the production of faulty products.

Can you provide examples of how Andon lights improve safety in manufacturing facilities?

Andon lights greatly enhance safety in manufacturing facilities by instantly notifying workers about safety incidents, such as equipment malfunctions or spills. This timely information enables workers to take immediate action to mitigate potential hazards and ensure a safer work environment.

Conclusion

Andon lights are like helpful guides in factories, silently showing the way to work more efficiently and achieve excellence. These special lights are placed strategically along production lines and use colors to convey important messages.

They can let workers know if a machine has stopped working if there’s a problem with the quality of the products, if there are not enough materials, or if there’s a safety issue.

These lights are an important part of lean manufacturing, which is all about reducing waste and improving efficiency. By quickly identifying and addressing problems, these lights help prevent delays in production and improve the quality of the products.

When it comes to andon lights, there are various options to choose from. Be sure to consider the manufacturing process type, the production line size, and the budget when selecting an andon light.

In addition, several vendors sell andon lights, so be sure to research to find the best option for your needs.