Batch flow, a production process where items are produced in groups before moving to the next stage, offers a unique solution.

This method is celebrated for its ability to handle diverse products and varying specifications, making it a favorite in industries like pharmaceuticals, food processing, and textiles.

The blog post discloses batch flow, exploring its advantages, challenges, and practical applications. The post also discusses the batch flow process vs the continuous flow process. Whether you’re in manufacturing or simply curious about production processes, understanding batch flow could be the key to unlocking enhanced productivity and adaptability in your business.

Definition of Batch Flow

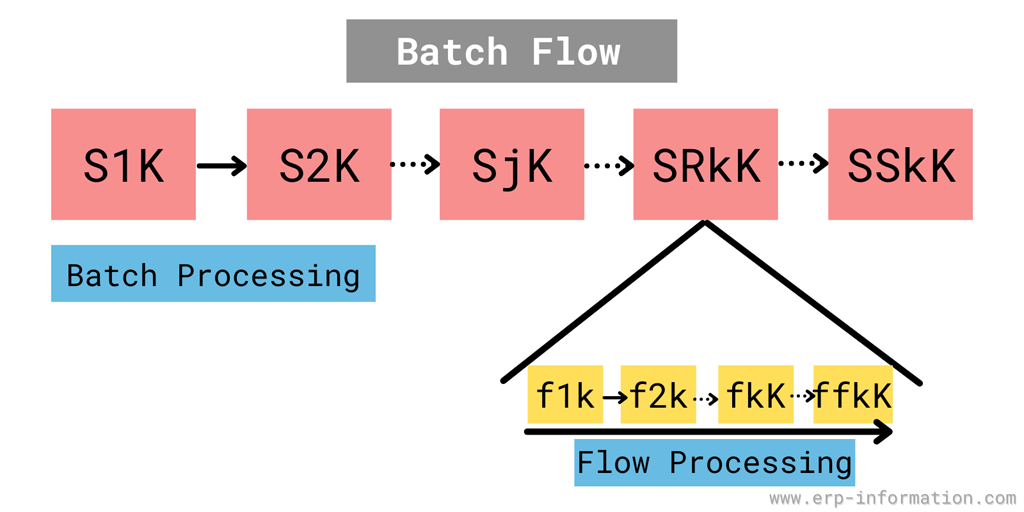

Batch flow implies that each unique batch is completed in one work center before the entire batch is moved to the next work center. In this process, subsequent batches should wait until the current batch moves to the next work center.

The production process is one of the success factors of the business. Batch flow is one of the essential and successful production processes. Because of this process, a manufacturer can produce multiple products simultaneously.

Advantages of Batch Flow Process

- It reduces the initial setup cost.

- It allows you to implement an entire system of batch-processing equipment easily and cheaply.

- It enables you to set up each process separately.

- It suits the pharmaceutical, rare metal, food, and packing industries.

- No need to concentrate on a single type of product. Hence it increases flexibility to produce other types of products.

The batch process is suitable for the clothing and seasonal products manufacturing industries. The cloth industry can manufacture different colored, different-sized clothes by adopting this process.

Disadvantages

Batch flow is not a suitable process for all types of industries. So we should know the disadvantages of it.

- Its processing cost is high

- Batch flow is a time and energy-consuming process

- Equipment used in the batch process requires more space.

- Additional laborers are required to move the products from one place to another.

Example of Batch Flow Process

For example, assume a textile industry provides towels, bedsheets, and pillow covers to a hotel they require for their business. With the batch process, it is easy to fulfill the orders of that hotel.

It is easy to produce 200 bed sheets, 1000 large pillow covers, 700 small pillow covers, 500 curtains, etc., with the help of one set of machinery.

With the flexibility of the batch process, the textile industry can immediately meet the demands of that particular hotel.

In the same way, for businesses like cookie baking, samosa baking, and sandwich making, the batch process is a good choice.

Because these businesses must supply their products when they are fresh as they have a short shelf life, hence in this case, batch production makes sense.

Suppose the cookies baking company produces a large shelf life of cookies; then the continuous process is efficient.

How Do You Bring Efficiency to Batch Flow?

Batch flow is less efficient compared to continuous flow. But somehow, you can bring efficiency in batch flow by following the below steps.

Decrease the possibilities of the type of products

If you are producing 16 to 20 cookies, ask yourself a question: Is it profitable to produce 16 to 20 types of cookies? Then review the demand for the cookies.

Find out the fast-moving cookies and produce only that type of cookies. Then, remove the slow-moving, less profitable types of cookies.

Still, you want to produce all varieties, then extend the manufacturing time for slow-moving cookies so that you will get more orders during the time of the process.

Move the employees during switchover time

Assume that you have 15 employees in the production of a batch, and you need to change the setup for another batch.

At that time, retain only one or two employees to change the setup and move other workers to another work until the setup is changed.

Employees utilize this time to clean up the place and assist the other employees.

Increase the cost of special batch

Some customers ask for customized or unique products. So that batch requires some extra setups. But, on the other hand, it reduces the number of switchovers. Hence charge more cost for those products.

Adopt lean manufacturing

The lean manufacturing method helps to decrease the switchover time. It reduces the wasteful process.

Continuous Flow Process

In this process, a single work unit moves between all stages without any breaks in time. Here flow of products or units takes place continuously.

The advantages of continuous flow are

- Saves time and energy

- It helps you to save money by reducing inventory and transportation costs

- Improves the quality of the product by identifying the faults easily

- Increases productivity

- Meets customer needs effectively compared to batch process

Batch Flow vs Continuous Flow

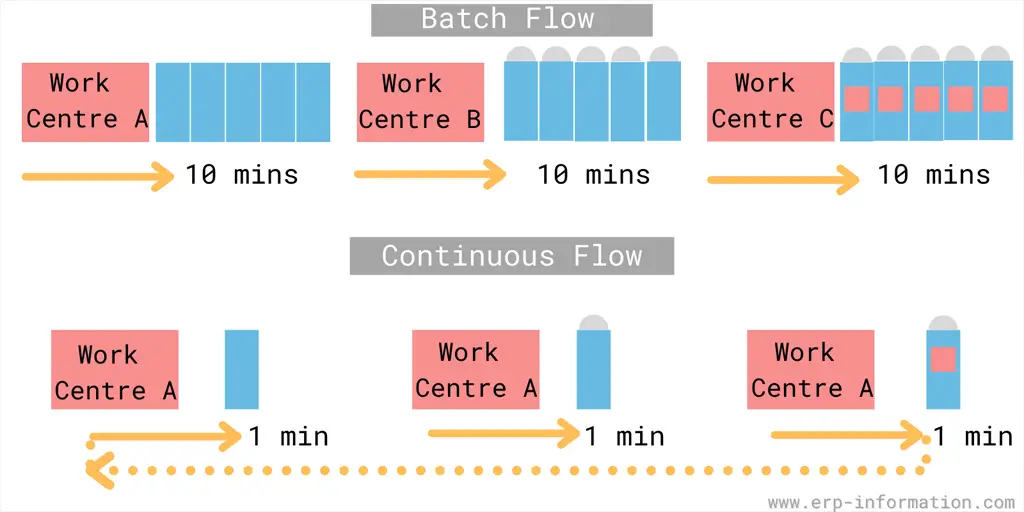

The above image shows the time consumption in both batch and continuous processes. The time taken for the first product in the batch process is 21 minutes. To produce one batch of 10 products takes 30 minutes.

The time taken for the first product in the continuous process is 3 minutes. Hence producing ten products takes 12 minutes.

Following are the significant differences between batch flow and continuous flow.

| Batch flow | Continuous flow |

| Equipment costs are low. | Equipment costs are high. |

| Difficult to maintain a good quality of products in the batch process because defects are not identified until the whole batch is completed. | In a continuous process, it is easy to find the defect in the product because, in this process, a single product moves between each stage of the process. |

| The production rate is high. | The production rate is low. |

| The shutdown happens more frequently. | The shutdown happens rarely. |

| Handling the process is very easy. | Handling the process is difficult. |

| This process requires a small workplace. | This process requires a large workplace. |

FAQs

What are the products produced using batch flow?

The batch flow products are baked items, computer chips, clothes, newspapers, magazines, books, electrical goods, and jig productions.

How does batch flow differ from continuous flow?

Batch flow involves processing items in discrete groups or batches and is often used for products with varying specifications or those that require different processing steps.

While continuous flow is a steady, uninterrupted process where items move continuously through production.

What types of industries commonly use batch flow processes?

This process is prevalent in industries like food processing, pharmaceuticals, chemical manufacturing, and electronics assembly, where products may have variations in ingredients, specifications, or configurations.

How is quality control maintained in batch flow production?

Quality control in batch flow involves monitoring and testing each batch separately. Statistical process control techniques, inspections, and quality assurance measures are employed to ensure consistency and product quality.

What are the challenges associated with batch flow production?

Challenges include managing inventory between batches, addressing setup and changeover times, optimizing batch sizes, and maintaining efficient production scheduling.

Conclusion

To summarize, batch flow is a system that works best for manufacturing and assembly line processes. It utilizes the concept of “batch size” to make an entire group of units move through production at once to minimize costs by reducing inventory levels (which require more space) and avoiding setup times between steps.

Continuous flow systems are also popular because they provide better customer service, allow faster response times during peak periods, reduce labor requirements on each step of the process, and keep up with changes in demand or product design without disrupting operations.

Some industries need batch flow, like pharma, food, and sensitive and rare metal industries. Some industries need continuous flow, like mining industries and material processing industries.

We hope you’ve found this post informative.