When something goes wrong on the production line, it can cause many headaches for workers and managers. This means that products are not being made properly, which can also lead to safety issues.

Andon Board is a visual management tool that helps quickly identify and solve production line problems. It uses color-coded lights to indicate the severity of the problem. This allows workers and managers to address the issue immediately.

This article will uncover the concept, andon board. It will discuss examples, uses, and advantages of the andon board along with the andon types, colors, and andon in lean manufacturing.

Andon Board Definition

Andon Board is a display board used in the manufacturing industry. It indicates the existence of a problem at a specific workstation. The issue might be technical or related to quality. The workers can push the button and notify the managers or other workers when they find an issue.

What does the word Andon mean?

The term “Andon” comes from the Japanese word for the paper lantern.

The Japanese call their form of quality control the “Andon” system. Andon means “guiding light,” which they use to acknowledge that jobs are done without interruption.

Toyota first discovered it, which utilized the Jidoka quality control method. It has now become an indispensable part of the Lean approach.

Andon meaning in manufacturing industries is “the status display.”

Jidoka is a Japanese term. The meaning of ‘Autonomation‘ is ‘Automation with a human touch.’

The system gives more authority to the workers. For example, they can stop production when they detect any particular defect.

Initially, these were light signals in the manufacturing process. They signaled the status based on the color.

Over time andon boards have evolved and are with far more superior technology. Modern alert systems use different modes to highlight the issues. Examples are pre-recorded verbal messages, text, and other graphic elements.

Though displays are sophisticated, their purpose has not changed: efficient communication and real-time status of the plant floor.

Different Levels of Andon

- Andon Light: It is a traditional Andon usually pull cord and light.

- Andon Board: The board that shows the status of all production lines of the organization in one central location.

- Andon System: It contains additional signal sources like sensors and alerts

- Andon Digital System: The digital system Integrates the concepts of Andon with digital manufacturing.

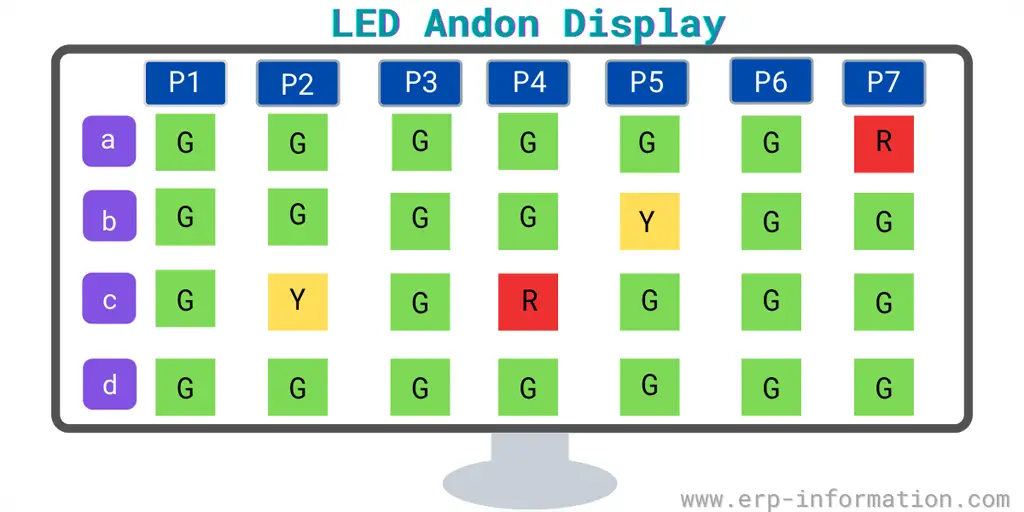

The below image shows the LED Andon Display of a manufacturing plant.

Andon Types

Operator controlled andons

Manual operators in the assembly line trigger the andons. They may do it by using static buttons, pulling the cord, or using a voice command in a few modern systems.

Machine controlled andons

These are automatically activated andons. When criteria fixed in the assembly line are not met or lacking, it is triggered.

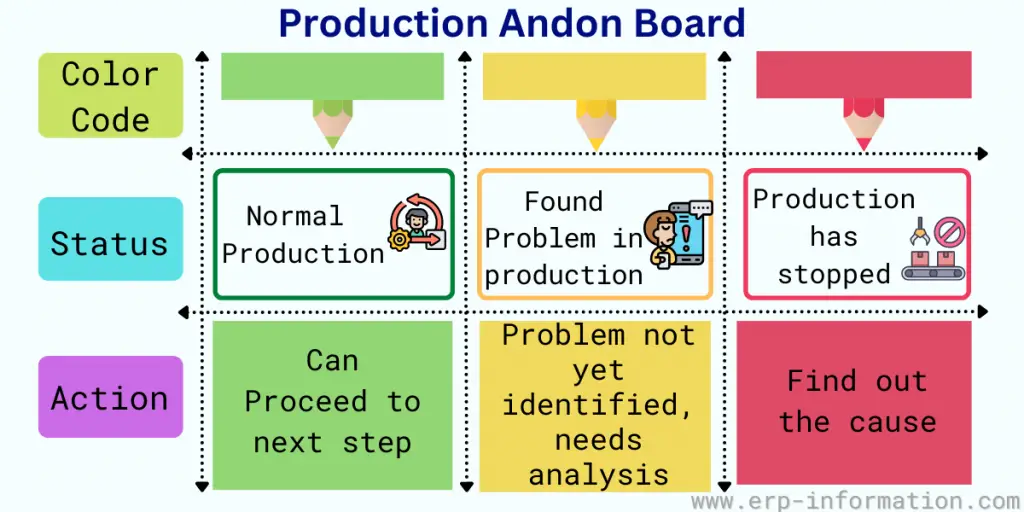

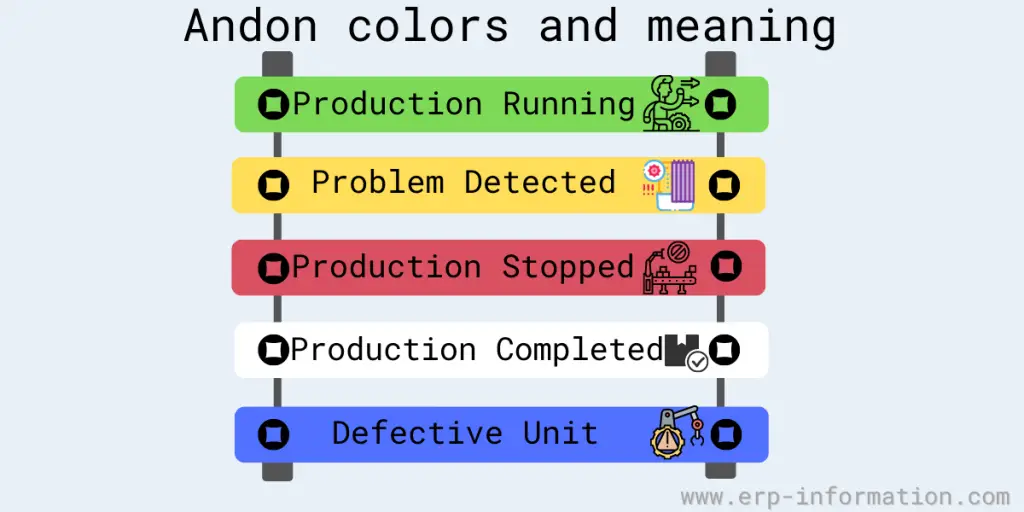

Andon Colors and Their Meanings

- Green – Production is running correctly and will move to the next level

- Yellow – problem detected, the operator needs assistance from an expert to fix the problem

- Red – Production stopped since the solution for the problem is not identified and needs further investigation

- White – Production run completed. The next run could be scheduled if required.

- Blue – Defective unit, this need not stop the process; even the number of faulty units could be displayed.

What is Andon in Lean Manufacturing?

Andon in lean manufacturing is a system that warns workers, operators, and managers about problems in real time. With the help of alerts, immediate corrective action can be taken.

It helps in addressing process or quality control issues with immediate attention. That further observes the reduction of production bottlenecks.

It clears any glitches that might lead to slow production. It also avoids complete production halts soon.

More specifically its uses in lean manufacturing plants are as follows.

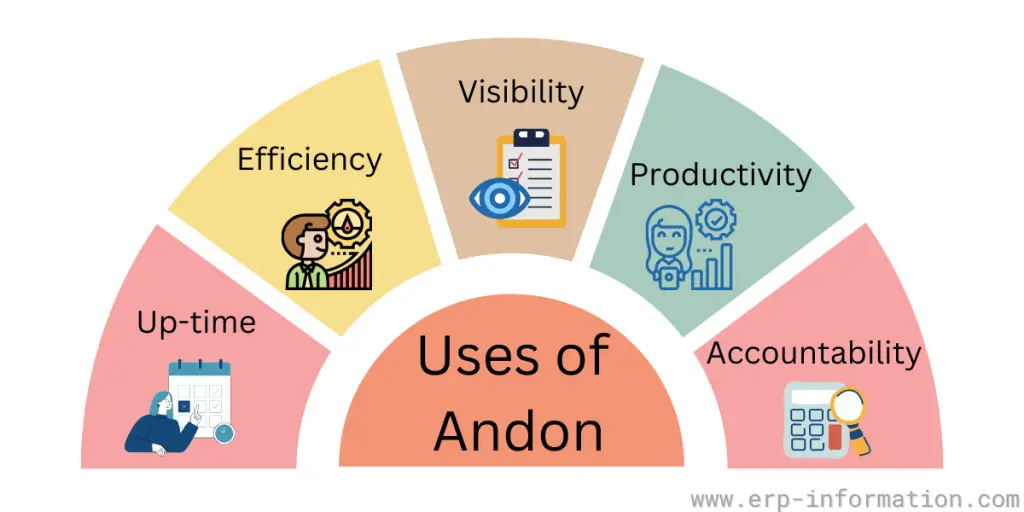

Uses of andon board in lean manufacturing plants

- Visibility – The possibility of fixing problems of downtime, quality, and safety in real-time

- Productivity – Attending to problems as they occur in the manufacturing process increases productivity

- Accountability – Effective delegation of accountability, and responsibility to operators

- Up-time – Since it helps in quicker identification and fixing manufacturing issues, downtime is reduced

- Efficiency – Provides an effective and consistent way of communication. That helps in saving money and time

Let us explore it with scenarios.

Scenario 1

In the car manufacturing industry, the production of vehicles takes place along with the indication light down the production line. Therefore, the lights will be red, green, and blue.

When an employee fixes a part of the car correctly, the indicator light goes from blue to green, and the vehicle goes continuously down in the production line.

If the employee fixes the part incorrectly, the indicator goes red, showing a yellow light to show that the problem is detected in that production line.

If the employee cannot fix it correctly and quickly, the production stops, and the team members gather and solve the problem in that production line.

Scenario 2

It is used in web-based companies also. But, of course, you all know the very famous online shopping site Amazon.

It uses andon for its customer service because providing good customer service is its top priority. Thus, Amazon calls it “customer service andon cord.”

Whenever a problem occurs in customer service, this cord alerts the manager to sort out the problem. Here andon is not aboard. It is a digital system.

Advanced Features of Modern Andon Systems

- Integrates with enterprise resource planning (ERP), computerized maintenance management system (CMMS), and manufacturing execution system (MES)

- Making extensive use of the Internet of Things (IoT)

- Issuing tickets with workflow

- Mobile client applications to get alert notifications

- Email, SMS, and mobile application push notifications

- Automatically track production counts and cycle time

- Big data analysis and reporting system about recorded events of andon inputs

Advantages of Andon Board

Saves time

Since andon board is a visual display, it allows you to understand the situation and problems in the production line. So that it helps to reduce the problem detecting time, avoids stopping the production line, and saves time.

Saves money

You know that in business, time is money. So when process time reduces, it helps to reduce production costs and leads to profit.

Increases communication

It helps flow information throughout the production line through visual or sound signals. Hence it improves the internal communication between workers, supervisors, and managers.

Controls process

The production andon board forecast the problem and allow the maintenance team members and higher management to have a perfect hold on the production line. It also helps to increase overall equipment efficiency.

Calculate your OEE with our Overall Equipment Efficiency Calculator

Collects accurate information

To support an effective management system, information about the function of the production line should move from lower-level workers to a higher authority. Andon board helps to collect accurate information about the production line.

Decreases hesitation

During production, sometimes workers hide issues. But when you start using andon, workers will be encouraged to find and solve the problems immediately. It helps to enhance downtime, product quality, and safety.

Enhances productivity

It allows the workers or operators to take immediate action when they find a problem without waiting for a higher authority. This rapid determination of the issues and solutions helps to increase productivity.

Zero interruption

It helps to move the assembly line without any interruption.

What Will Be the Future?

Andon board manufacturers are looking for ways to improve the traditional system while maintaining simplicity.

While many andons can be used in lean manufacturing plants, the most common type is a red light with an audible sound or buzzer.

In the future can expect complete Automation of detecting the problems and notifying them in manufacturing plants.

They are building machine learning models based on andon inputs for different industry verticals. With these models, input patterns could be analyzed better for future enhancements.

Replace cords, buttons, and screens in legacy systems with modern systems will be inevitable.

FAQs

What is an example of Andon in everyday life?

Your car’s dashboard is the best example. It warns you about the existence of fuel, whether it is complete or finished.

One more example is when a Xerox machine or scanner has problems. It warns the operator with a signal light.

What is the purpose of andon board?

The primary purpose of an andon board is to swiftly notify operators of any issues occurring on the production line. Serving as a real-time alert system, andon ensures that operators are promptly informed about any disruptions in the manufacturing process.

This immediacy is crucial as it empowers operators to address the problem at its source, right on the spot. By doing so, the andon system facilitates a rapid resolution, allowing the assembly line to resume its normal operation without prolonged interruptions.

In essence, the Andon board acts as a proactive tool, enabling efficient problem-solving and contributing to the overall smooth functioning of the production process.

What types of information are typically displayed on an andon board?

An Andon board typically displays a spectrum of critical information essential for real-time monitoring and efficient decision-making in a manufacturing setting.

Production Status

Real-time updates on production progress, highlighting whether the assembly line is operating within expected parameters.

Machine Status and Alerts

Immediate notifications about any malfunctions or abnormalities in machinery, allowing swift response to prevent disruptions.

Quality Control Metrics

Metrics related to product quality, defect rates, and adherence to quality standards, enabling operators to address issues promptly.

Workstation Efficiency

Information on the efficiency of individual workstations or production cells, aiding in identifying bottlenecks or areas for improvement.

Conclusion

The Andon Board is a critical element of lean manufacturing. It can serve as your early warning system for potential problems. It would help if you never forgot the importance of having an engaging, informative board that employees can easily read from anywhere in the plant.

This blog post has given some background on what an Andon Board is and how it can increase efficiency and reduce waste by providing feedback and information about production levels during the day or night.