If you’re in the business of storing perishable goods, then you need to know about cold storage warehousing.

This post will explain everything you need to know about cold storage warehouses, from what it is, how it works, and what types of it. We’ll also look at the sustainability of cold storage warehousing and some of the challenges that come with it.

So whether you’re just starting in the food industry or looking for ways to improve your current cold storage setup, this guide has you covered.

What is a cold storage warehouse, and what are its benefits?

A cold storage warehouse is a specially-crafted facility that keeps temperature-sensitive products safe and secure.

Built with insulation and additional climate control features, these warehouses have an ordinary facade but are equipped with the power of preservation beneath their exterior walls.

It offers many benefits,

- It is a specialized facility that stores perishable goods at a controlled temperature.

- Including extended shelf life for products, reduced spoilage and pest infestation risk, and improved product quality.

- This storage also helps reduce energy costs by eliminating the need for air conditioning or refrigeration systems.

How does it work?

A cold storage warehouse maintains the stored goods at a controlled temperature, usually between -5 and 10 degrees Celsius (23 and 50 Fahrenheit).

This is done with specialized equipment like air-conditioning units, refrigeration systems, and insulation to help keep the goods cool.

Other measures, such as fans, condensers, and dehumidifiers, are also used to maintain the appropriate temperature.

Types of cold storage warehouse

There are two main types:

1. Freezer warehouses

Freezer warehouses store goods at between -30 to 0 degrees Celsius. To guarantee optimal and safe storage, a freezer warehouse must remain at an unwavering temperature to protect its contents from harm.

Proper cold storage conditions are critical for companies that need frozen products stored for long-term preservation.

A freezer warehouse must always stay at a consistent temperature to protect items such as food and medical supplies. An interruption or fluctuation in temperature can lead to spoilage, which can be costly.

That’s why it’s essential to have a reliable cold storage warehouse where goods will remain safe until they are taken out of cold storage and distributed.

2. Refrigerated cold storage warehouses

Refrigerated storage warehouses, also known as cold storage warehouses, are essential to maintaining food quality.

These warehouses are tightly insulated and equipped with powerful refrigeration systems that can maintain product temperatures as low as 0 to 10 degrees Celcius.

( It may vary according to need) keeping food at an optimum temperature, cold storage warehouses help prevent spoilage and extend product life significantly- a feat impossible without cold storage technologies.

Furthermore, cold storage services benefit businesses since they provide a cost-efficient way to manage their products instead of purchasing additional cold storage equipment.

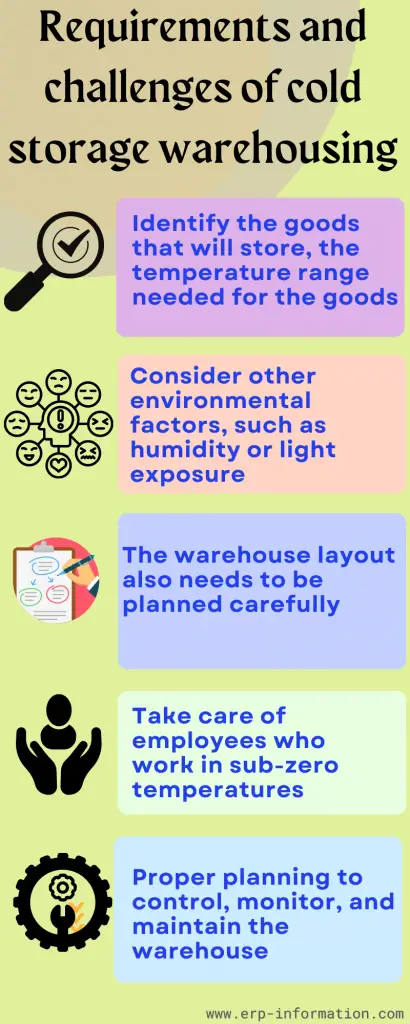

Requirements and challenges of cold storage warehousing

It has specific needs and challenges to examine before setting up a warehouse.

- It is important to identify the goods that will store, the temperature range needed for the goods,

- You must consider other environmental factors, such as humidity or light exposure.

- The warehouse layout also needs to be planned carefully, and there may be additional costs for the necessary equipment.

- Take care of employees who work in sub-zero temperatures: Employees should cover themself with full clothes, gloves, and jackets.

- Proper planning to control, monitor, and maintain the warehouse.

Working in a cold storage warehouse

It can be physically demanding, as employees are often required to work in temperatures that range from -15 to 10 degrees Celsius (5 and 50 Fahrenheit).

Employees must wear protective clothing like insulated jackets, hats, and gloves to protect against cold temperatures.

It is always important for employees to be aware of their health and safety, as they may be exposed to hazards such as slips and falls due to icy surfaces.

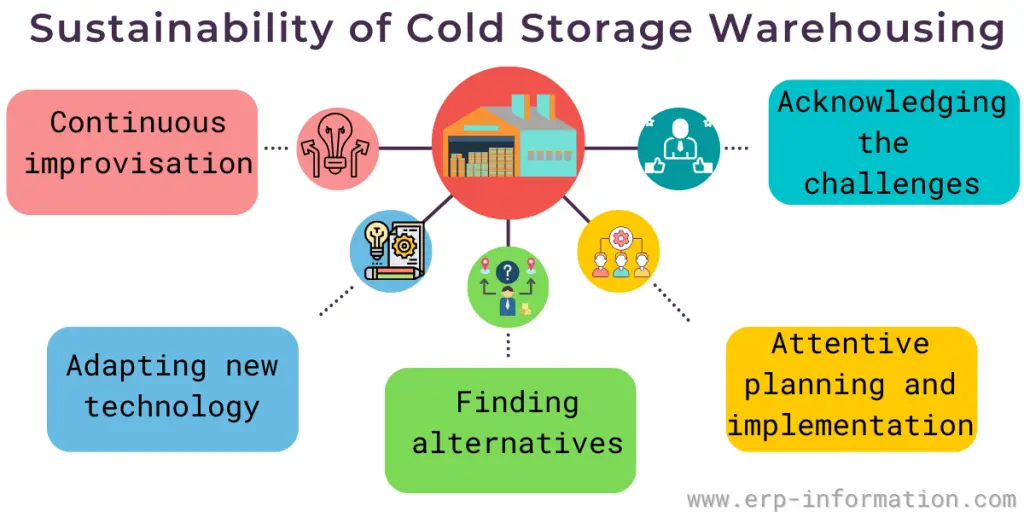

Sustainability of cold storage warehousing

Cold storage warehouses consume a lot of energy, making them an unsustainable option in many cases. However, there are some ways to make cold storage warehousing more sustainable.

Continuous improvisation

Improving insulation, installing energy-efficient lighting and refrigeration systems, for example: Using LED lighting, Carbon dioxide cascade refrigeration system, using more efficient motors, Optimized thermal envelopes, Using white TPO roof membranes, and many more.

Adapting new technology

Adapting new technologies and cold storage software for better results

Finding alternatives

Considering alternative cooling methods such as evaporative cooling or natural airflow.

Attentive planning and implementation

Creating a sustainable cold storage warehouse with attentive planning and implementation is possible. It helps to maintain product quality while reducing energy costs and environmental impact.

Acknowledging the challenges

By understanding the requirements and challenges of cold storage warehousing, companies can make informed decisions about how best to store their goods.

What is cold storage software, and how does it work?

Cold storage software is software for managing and automating the operations of cold storage warehouses.

- It can help improve efficiency by automating inventory control, temperature monitoring, order processing, and shipping.

- The software can also provide real-time product quality and safety information and track energy usage to help reduce costs.

- Cold storage software can help reduce human error, improve safety, and ensure compliance with regulations.

- Depending on the software, it may also provide features such as alerts for temperature changes and automatic system optimization.

- By utilizing cold storage software, companies can make their operations more efficient and cost-effective while helping to ensure product quality and safety.

What is cold storage inventory management system?

Cold storage inventory management system is a software solution used to manage the operations of cold storage warehouses.

- This includes tracking product inventory, organizing storage areas, and managing warehouse staff.

- The software can help streamline processes, reduce errors and improve overall efficiency in the warehouse.

- It can also provide valuable insights into customer demand, allowing companies to better plan for future needs.

What is 3PL cold storage? How does it work?

Third-Party Logistics (3PL) cold storage is a warehousing service provided by an external company.

- The 3PL company will manage the warehouse, arrange transportation, and provide customer service.

- This allows companies to focus on their core business activities without worrying about managing the warehouse or logistics themselves.

- With third-party logistic cold storage, companies can benefit from the expertise and cost savings of using a third-party provider.

Vendors of the 3PL cold storage

- Americold Logistics

- Burris Logistics

- FST Logistics

- H&M Bay Inc.

- Hanson Logistics

- Lineage Logistics

- Versa cold Logistic Services

- Conestoga Cold storage

- Holt Logistics

Advantages and Disadvantages

Advantages

Cold storage warehousing offers many advantages for companies that store their goods for extended periods.

- This improves product shelf life.

- Reduced the risk of spoilage and food safety hazards

- Increases the product quality due to the controlled environment

- It can also help to reduce energy costs due to the efficient cooling systems used in cold storage warehouses.

Disadvantages

Although cold storage warehousing offers many advantages, some potential drawbacks must be considered.

- It requires additional costs for equipment and maintenance

- The cost of staffing for the warehouse will be more

- This can also be difficult to maintain and may require frequent inspections to ensure safety regulations are being met

FAQs

What are some sustainable practices in cold storage warehouses?

Sustainable practices include energy-efficient refrigeration systems, use of renewable energy sources, waste reduction and recycling initiatives, optimized transportation routes to reduce emissions, and adherence to eco-friendly packaging materials.

How do temperature-controlled logistics work in cold storage warehouses?

Cold storage warehouses use refrigeration systems to maintain specific temperature ranges suitable for different types of goods, ensuring they remain fresh and safe for consumption or use.

Conclusion

With the right approach, cold storage warehouses can effectively store goods while reducing energy costs and environmental impact; this can be a sustainable and cost-effective solution for many companies.

Hopefully, this guide has provided sufficient information about cold storage warehousing. Whether you’re considering setting up a cold storage warehouse or want to learn more about how cold storage works, this guide should provide a good overview.