Digital Twin is a revolutionary technology gaining traction in the construction industry. Digital twin in construction allows companies to create a digital representation of their existing physical work environment, giving them greater insight into how they can improve operations and efficiency.

Digital twins often incorporate data from various sources, including sensors, GPS tracking, aerial photography, drones, etc.

By creating this virtual replica of an asset or structure, businesses can accurately monitor their progress, predict outcomes, detect issues quickly, and optimize resources for maximum efficiency.

Additionally, it provides key insights into the entire life cycle of a project, from design to optimization and beyond. The digital twin has the potential to revolutionize how we approach construction projects by making them safer, faster, and easier to complete.

This blog post will provide complete information on digital twin in construction, their benefits and disadvantages, and where they can be implemented.

Definition

A digital twin is a digital representation of a physical asset or system used to monitor its performance, identify areas for improvement, and predict future outcomes.

It consists of detailed information such as dimensions, environment, data points, and other information that allows users to accurately track the performance of the asset or systems in real time.

A digital twin also enables companies to create virtual models or simulations of their assets to test different parameters and scenarios before implementing changes in the real world. Industry 4.0 uses technology to improve things in many ways.

Digital twins are a common technology in Industry 4.0 that helps create better products and services.

Benefits of the digital twin

Digital twins are digital replicas that can be used to see how a digital asset is designed and if it is running as it should.

- It can give in-depth insight into occupant behavior, changing use patterns, and space utilization.

- Digital twins offer the opportunity to gauge possible results of design changes and varied external conditions like the weather Before they are implemented in real-life scenarios.

- The digital environment collects data from all these varying circumstances for further observation and understanding — providing an incredibly useful tool in construction projects.

What is digital twin in construction?

Digital twins are revolutionizing the construction industry, creating a seamless link between form and function. It includes Architecture, Engineering, and Construction of buildings (AEC).

Providing an accurate virtual representation of physical infrastructure in real-time allows stakeholders to analyze every detail needed for successful completion – before any ground is even broken! A digital twin is an online, real-time representation of a physical asset or process.

In the construction industry, a digital twin can be used to model and simulate the performance of a construction project to identify issues and potential problems before they arise. This allows for earlier identification and resolution of issues, saving time and money.

Benefits of digital twin in construction

- Digital twins provide an immersive virtual experience, enabling users to interact with the space of a building as if they were standing in it.

- Through detailed simulations of its different systems and subsystems that make up the environment,

- Digital twins in construction give us more than just blueprints–they show people how spaces may be used before construction even begins.

How do digital twins work in the construction industry?

A virtual model of a physical construction project is created in order to implement the digital twins process. This virtual representation is created using data collected from 3-D sensors, cameras, drones, and other sources. Simulation of the construction process carried out on the digital twin.

Here we discuss a few steps used in the process of implementing digital twin in construction:

- Data collection: The first step is to collect data from the physical construction project. A variety of sensors, such as scanners, cameras, GPS devices, and drones can also be used for data collection from the project site.

- Creation of 3D model: The collected data helps render a 3D model of the construction project which is the main base of the digital twin.

- Data integration: The 3D model generated is further fused with project plans, schedules, cost estimates, and other data sources. This integration of data allows the digital twin to simulate the construction process and identify the potential problems.

- Simulation: The entire construction process can be simulated using the created digital twin and used to identify potential issues, address problems that may arise between different building components, and devise strategies to resolve these issues.

- Collaboration: Widely dispersed teams both off-site and on-site can seamlessly and efficiently collaborate and coordinate with the aid of accessible technology.

- Finer-tuning: Optimization of the construction process can also be achieved with digital twins. Identifying better ways to sequence the construction activities or optimizing the placement of materials is also possible.

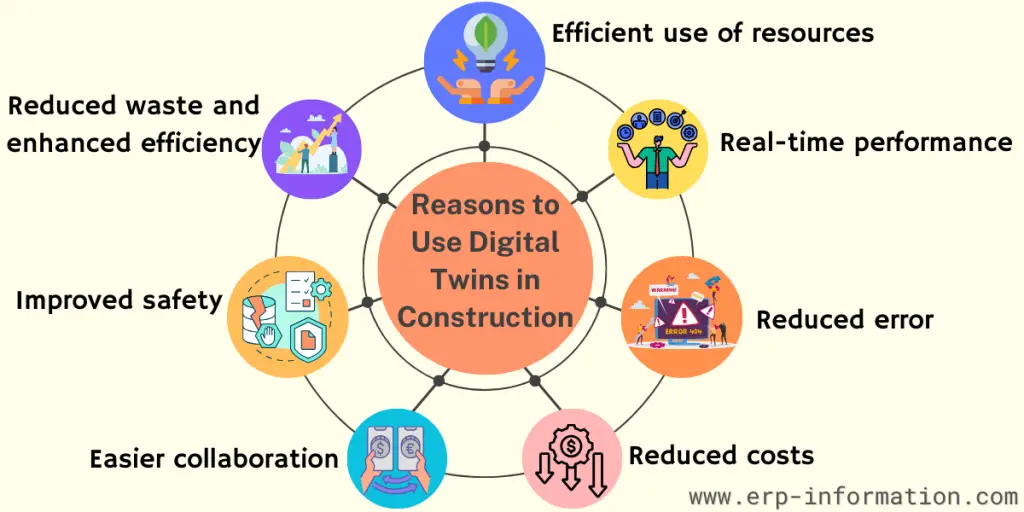

Reasons to use digital twin in construction

Some of the major reasons to use digital twins in construction projects include the following:

Reduced waste and increase in efficiency

By having a virtual model of the project, it becomes much easier to detect errors and potential problems. This can lead to less waste and increased efficiency as fewer construction mistakes occur.

Improved safety

A digital twin in construction can help identify potentially dangerous situations before they occur, thus improving safety on the construction site.

Easier collaboration

With a digital twin, multiple stakeholders can collaborate on a project more easily than ever before. This can lead to faster completion times and improved overall results.

Reduced costs

The use of digital twins can help reduce costs by helping More efficient project planning and execution.

Reduces the error

Reduced errors and rework due to improved communication

Real-time performance

Real-time performance monitoring for quicker identification and resolution of issues.

Efficient use of resources

Optimizing resources, scheduling tasks, and construction methods.

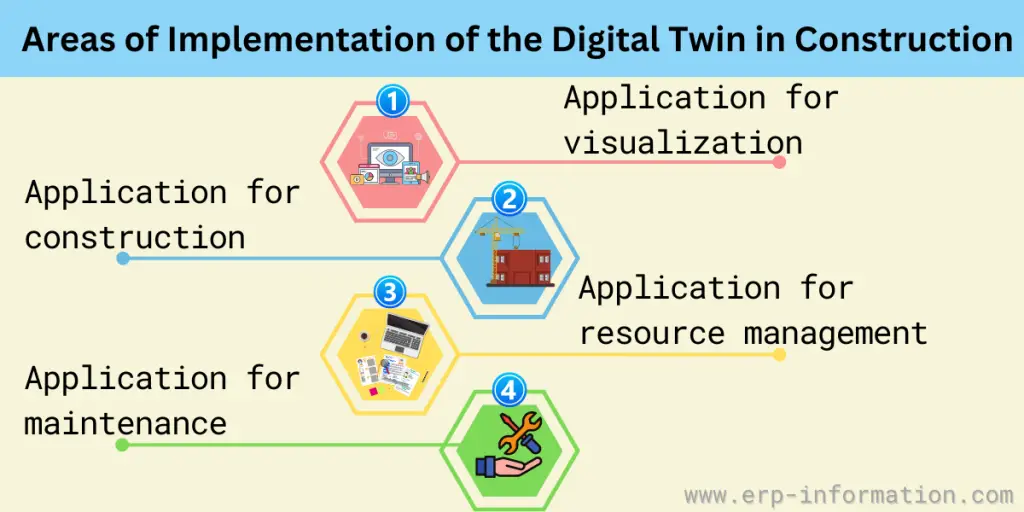

Areas of implementation of the digital twin in construction

Digital twin technology has a wide array of applications in construction,

Application for visualization

It can be implemented by helping visualize, track, and manage complex designs to predict future outcomes of a project.

Application for construction

In construction, it provides insights into how assets and structures can be built more efficiently and with greater accuracy.

Application for resource management

It also allows companies to maintain efficient operations by monitoring and optimizing their resources, such as equipment, materials, and labor.

Application for maintenance

Digital twins enable teams to detect issues early on and proactively adjust operations to ensure that projects stay on track. By leveraging these tools, businesses can achieve higher levels of success on construction projects with less risk involved.

Difference between digital twin and BIM

| Digital twin | BIM |

| This technology takes this one step further by providing a digital representation of physical assets and systems to monitor their performances, identify areas for improvement, accurately track their operations and predict future outcomes. | Building Information Modeling (BIM) is a 3D model-based process for planning, designing, constructing, and managing buildings and infrastructure. |

| These are more dynamic as they can simulate different scenarios before implementation in the real world. | It helps teams coordinate various components of the building process, like construction scheduling and resource allocation. |

| It also allows businesses to perform preventative maintenance on their assets and systems to reduce operations risks. | Risk management and project management are possible. |

| It focuses on real-time data and provides pictures and structure in real-time. | It is not designed for real-time operating systems. |

| Anticipates the forecast, such as weather and energy demand, is possible. | Prediction of the future or the weather is not possible. |

Disadvantages of the digital twin in construction

- The whole process depends on the internet facility.

- Not suitable for areas of construction that are out of reach.

- It can be expensive to implement and maintain and can be a barrier for smaller construction companies.

- The digital twin is completely based on 3D and CAD technology, with no 2D drawings.

- Requires specialized skills and expertise, which can be difficult to find and expensive to hire.

- It is important to implement robust security measures to protect this data from unauthorized access.

- Regular maintenance is necessary for managing data accuracy but the process is expensive and time-consuming.

Software for digital twin in construction

- Asite

- Maplesim

- Aedifion

- Imerso

- Azur Digital Twins

- Allplan Engineering in Civil

- SmartworldPro

FAQs

What are the examples of digital twins used in construction?

Here are a few examples of digital twins in construction:

Singapore’s Digital Twin: The Singapore government is developing a digital twin of the city-state. This digital twin will plan and manage urban development, transportation, and other public services.

Dubai’s Museum of the Future: The Museum of the Future in Dubai is one of the most advanced buildings in the world. It has a digital twin that monitors and optimizes the building’s performance.

Crossrail: Crossrail is a major infrastructure project in London. A digital twin was adopted to plan and manage the project’s construction.

The Shard: The Shard is a 95-story skyscraper in London. It has a digital twin is used to optimize the building’s energy usage and reduce its carbon footprint.

Takenaka Corporation: Takenaka Corporation is a Japanese construction company. It uses digital twins to manage its construction projects and improve its operations’ efficiency.

Conclusion

The digitalization of construction is inevitable. As construction companies worldwide are turning to digital tools and processes to survive and thrive in today’s competitive landscape, the need for a comprehensive understanding of how to implement and use digital twins will only become more urgent.

This blog post has given you a complete understanding of the benefits of digital twin technology and its potential application areas within the construction industry.

With the right implementation plan, the digital twin in construction can help companies save time and money, improve safety, and increase efficiency.