An increasingly popular concept for digital transformation, a digital thread allows information to flow from one department to another department, teams, and organizations.

It has the potential to revolutionize how people communicate within their companies, as well as how they create and deliver products and services to customers.

The article will discuss the definition of the digital thread, its benefits, examples, and digital thread vs digital twin.

What is a digital thread?

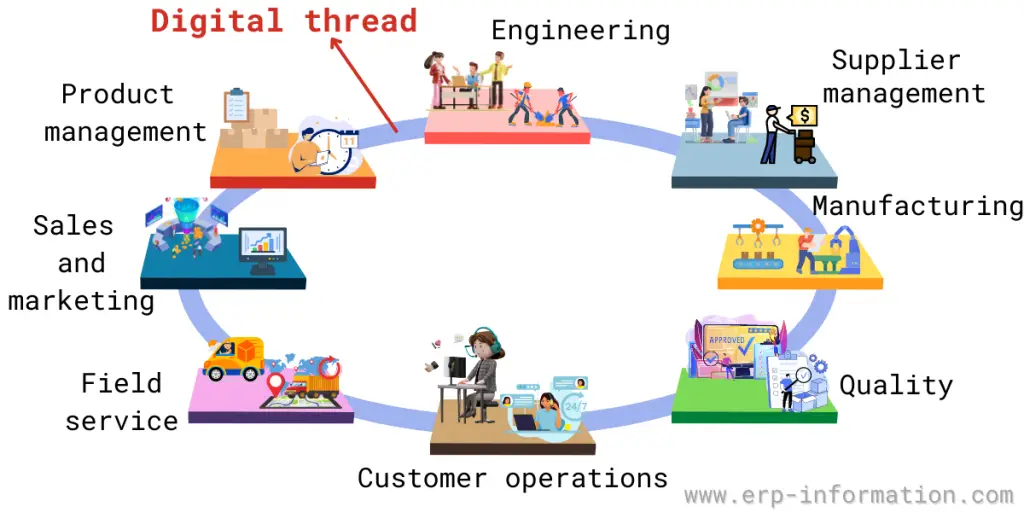

It is an interconnected system of data, processes, and applications that allows information to flow seamlessly between teams, departments, and organizations.

It is a concept used in digital transformation that enables organizations to manage and track activities across the entire life cycle of a product or service, from design to delivery.

By tying together disparate systems such as CAD/CAM, Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP), and Manufacturing Execution Systems (MES), the digital thread offers more efficient collaboration, better decision-making, and increased visibility throughout the life cycle of any project.

With the right strategy in place, It can be used to gain meaningful insights into product lifecycles, improve customer satisfaction, and increase organizational resilience.

Importance

The digital thread is essential because businesses now work globally, create complex products, and have lots of data to manage. They also need to follow rules and regulations.

Digital Threads are like a trustworthy guide. They help companies see things better, avoid mistakes, and work more efficiently. They also help everyone work together better.

These digital threads are used in different industries, like making planes, healthcare, and making things in factories.

They keep an eye on how well airplane engines work, manage how things move in factories, make sure medical devices are safe, and make factories run smoothly.

In today’s competitive world, using digital threads isn’t a choice; it’s a must. They are the compass that shows companies the way to success.

They help businesses stay relevant and even get ahead of the competition. With the power of digital threads, companies can change how they work and find new opportunities to grow and be creative.

Benefits

Improved collaboration

With a digital thread, teams are better connected and can communicate more efficiently in real-time, resulting in ongoing dialogue and collaboration throughout the life cycle of any product.

Enhanced decision making

By linking the various processes into one system via the digital thread, decision-makers can access more accurate data and greater visibility over company activities and operations.

Increased efficiency

The interconnected systems within a digital thread enable streamlined workflows and automated tasks, which result in improved efficiency across the organization.

Reduced cycle time

By having all data necessary for decision-making accessible in one place, cycle times for projects or processes can be significantly reduced as decisions are made quickly with no need for manual interventions or double-checking of information.

Better customer satisfaction

By giving customers access to reliable data about their products or services through the digital thread, companies can provide improved customer service, which leads to greater customer satisfaction.

Increased resilience

Adopting a digital thread is an important step towards organizational resilience since it enables more efficient reporting, monitoring, and tracking of business processes which helps to identify potential issues before they become problematic.

Greater visibility

With the data collected by a digital thread easily accessible in a single platform, organizations gain increased visibility into their activities and operations, which helps them better understand their performance over time and make informed decisions based on this information.

Digital thread examples

- Examples include asset tracking systems, digital supply chain management solutions, customer intelligence platforms, and predictive analytics tools.

- This system is also used in manufacturing to connect design and production data, allowing for more accurate monitoring of products throughout the entire lifecycle.

- These systems can be leveraged for remote collaboration, allowing distributed teams to access the same information and share resources in real-time easily.

- Finally, many industries are using this technology as a basis for AI and machine learning applications, enabling them to make better decisions faster.

Real-life examples

Some of the Real-life examples are as follows.

- Smart building systems, such as security and surveillance systems,

- HVAC automation and environmental sensors.

- It is used in healthcare to connect patient records, care plans, and medical devices, allowing healthcare personnel to access the information immediately.

- It is used in the automotive industry to provide drivers with better navigation assistance and improved safety features.

- Many industries use it for predictive analytics and real-time decision-making solutions.

How does digital thread enable digital twins?

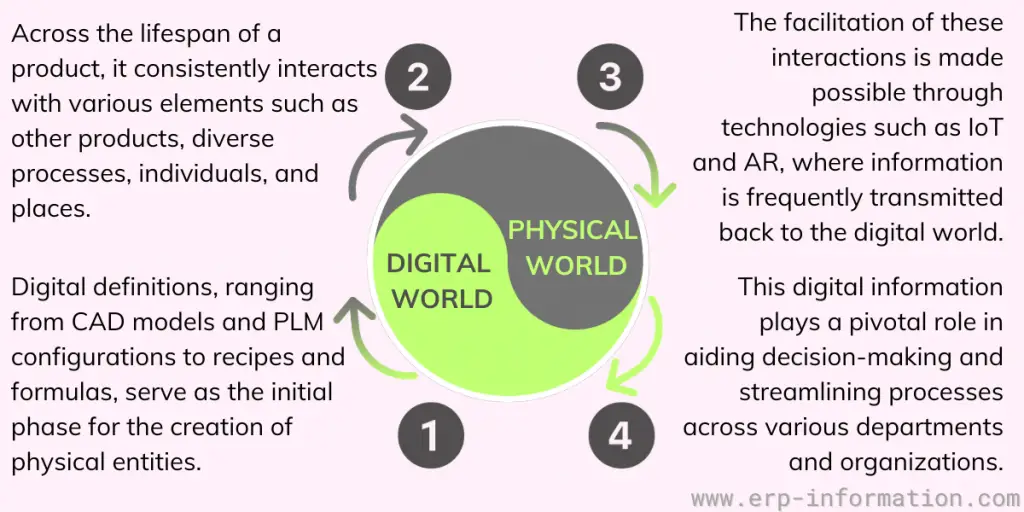

It enables digital twins by connecting all related data and processes into a single system across a product’s life cycle from design to delivery. That allows for the creation of a virtual representation of an object or system that can be monitored and adjusted in real time.

Data from various connected systems are aggregated and presented in an interactive, user-friendly interface, providing powerful insights and improved decision-making.

Digital twins also allow businesses to simulate scenarios and quickly test different approaches before they take action, resulting in better outcomes with minimal risk.

In addition, as digital twins are constantly updated with new information, organizations are more agile and able to better anticipate changes in their environment.

Digital Thread vs Digital Twin

Digital thread and digital twin are related concepts in the field of digital technology and manufacturing, but they serve different purposes and have distinct characteristics.

Here are the key differences between them:

1. Purpose

The primary purpose of the digital thread is to provide a seamless and interconnected flow of data across various stages of a product’s lifecycle, improving visibility, traceability, and collaboration.

Digital twins are used for analysis, simulation, monitoring, and optimization. They allow you to gain insights into the real-world operation of a product or system and can be used for predictive maintenance and performance improvements.

2. Domain

The digital thread focuses on data and information integration, enabling the efficient exchange of data across different phases of a product’s lifecycle. It provides a historical and contextual view of data but doesn’t necessarily simulate the physical behavior of the product.

The digital twin is a specific digital representation of a single physical entity, like a machine, building, or product.

It replicates the physical entity’s attributes and performance characteristics and is often used for analysis, simulation, and decision-making related to that entity.

3. Lifecycle Stages

The digital thread typically spans the entire product lifecycle, including design, manufacturing, testing, operations, and maintenance. It ensures data continuity and traceability across these stages.

Digital twins are often used during the operational phase of a product’s lifecycle. They provide a real-time representation of a physical asset’s behavior, allowing for analysis, monitoring, and performance optimization.

4. Characteristics

The concept of a digital thread involves the integration of data to facilitate the seamless flow of pertinent information throughout a product’s lifecycle, without necessarily generating a virtual representation of the physical entity.

In contrast, digital twins are characterized by the creation of a virtual model representing a physical entity.

These models serve various purposes such as predictive analytics, simulations, and informed decision-making by utilizing real-time data derived from the corresponding physical asset.

FAQs

What exactly is a digital thread?

A digital thread is like a live stream of data and knowledge that effortlessly travels through every stage of a product’s existence.

It kicks off during the design and engineering stage and accompanies the product through manufacturing, operations, and servicing.

This thread acts as a single, reliable source of information for everyone involved, making teamwork and smart choices easier.

What benefits can be obtained by implementing a digital thread in business operations?

Implementing a digital thread offers many benefits, to name a few:

– Improved visibility and traceability throughout the entire product lifecycle.

– Minimized errors and the need for rework.

– Improved operational efficiency and productivity.

– Streamlined decision-making processes.

– Strong collaboration among all stakeholders involved.

Conclusion

In conclusion, digital thread provides organizations with the tools they need to remain competitive and efficient.

By securely and accurately connecting data from different sources, businesses can reduce costs, increase operational efficiency, and improve customer experience.

Furthermore, by streamlining processes with advanced tools like Asset Trackers, CyberX Cybersecurity Platform, and Predix Industrial IoT Platform, companies can gain real-time insights into their operations that will lead to growth and success.

Reference