Additive manufacturing software plays a pivotal role in shaping innovation and driving the transformative power of 3D printing technologies.

As we navigate the intricate terrain of digital design and fabrication, selecting the right software becomes a cornerstone for success.

There are many different types of software for additive manufacturing, and it can be tough to decide which one is the correct one for you.

We’ve put together a list of the ten best additive manufacturing software solutions along with their pros and cons to enable you to make the right decision for your needs.

What is Additive Manufacturing Software?

Additive manufacturing software allows users to create or edit 3D models and convert them into instructions for a 3D printer.

Additive manufacturing software typically offers a wide range of editing features and the ability to export files in multiple formats compatible with different types of printers.

In addition, some additive manufacturing software solutions include additional tools like parts assembly, simulation, and performance analysis.

Here are 10 of the best additive manufacturing software

1. Ansys

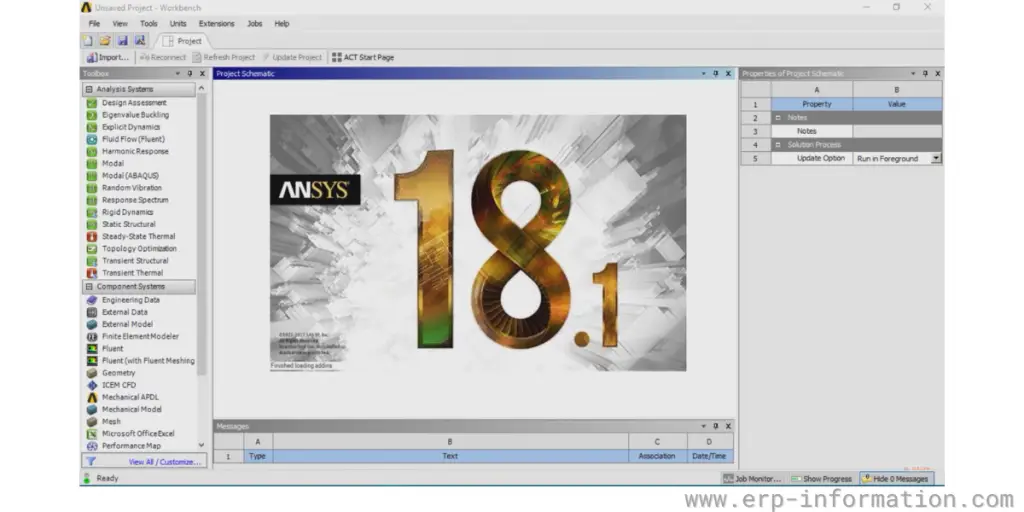

Ansys Additive Manufacturing Solutions (AMS) is a comprehensive suite of software tools that enable engineers to design, optimize, and validate parts and assemblies for additive manufacturing.

Using it, engineers can predict how a part will perform when printed using various additive manufacturing processes, identify potential problems early in the design process, and make changes to avoid them.

Features

- Process simulation: By using process simulation for metal Powder Bed Fusions, Directed Energy, Deposition, and Metal Binder jets, users can identify and minimize the risk of build errors and ensure high-quality parts.

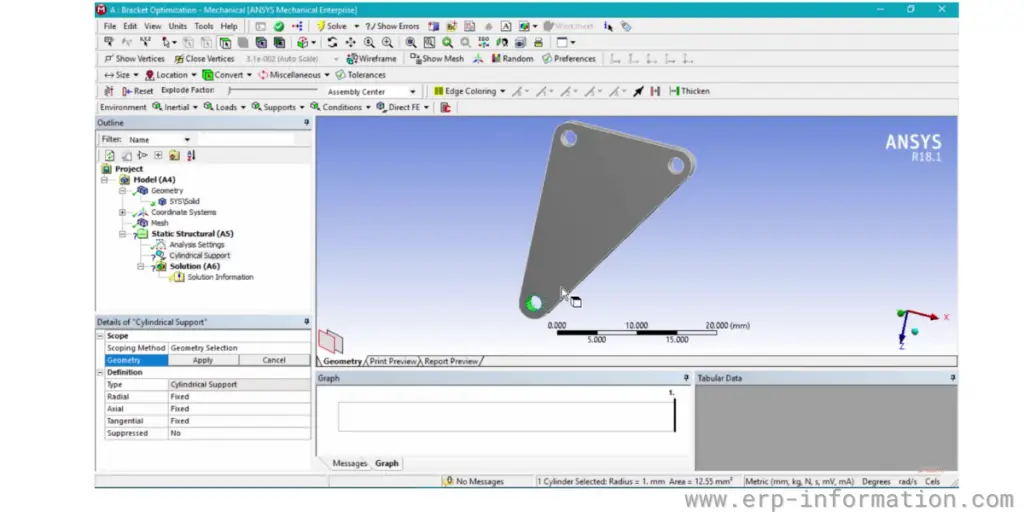

- Topology optimization: Ansys Topology Optimization produces design insights in real-time, which drives lightweight design possibilities faster. That helps reduce waste and increase efficiency while still meeting design requirements.

- Printability checking: The software checks for potential problems that could occur during the additive manufacturing process, such as porosity or delamination.

- Data acquisition and management: Ansys AMS helps manage the data associated with additive manufacturing, including process settings, build files, and post-processed data.

- Structural analysis: The software includes tools for analyzing the structural integrity of additively manufactured parts.

- Directed energy deposition: Ansys AMS supports the Directed Energy Deposition process, which builds parts with complex geometries.

Screenshots of Ansys

Pricing

The vendor does not provide pricing details. Contact the vendor directly to get details.

- A free trial is available.

- Ansys simulation software license courses are free for students at every level.

Likes

- It enables engineers to efficiently and accurately design and simulate complex mechanical systems. Doing so helps them validate designs, reduce prototyping costs, and bring products to market faster.

- It allows users to study different materials’ behavior under various loads and conditions. As a result, it can help users select the most appropriate materials for their applications.

- It provides an invaluable tool for stress analysis. By using it, engineers can assess the strength of individual components and identify potential failure points.

- With Its latest updation of topology optimization features, you can get accurate results against shape optimization.

- It helps to simplify CFD and CAD modeling.

Dislikes

- The user interface is not easy, as you must learn much about this software tool before using it.

- A high-end computer is required for the premium version, which will be more expensive.

- There have been reports of occasional crashes.

- Hard to build complex features

- Simulations need more processing power and time

- Difficult to run simulations on laptops

- It is expensive compared to other CAD software

- Lack of advanced features

Supported industries

- Aerospace

- Automotive

- Defense

- Energy healthcare

- High tech

- Industrial Equipment

Other details

| Language support | English |

| Intended users | Small business, mid-size, and large business |

| Training | Provides training in documentation form |

User opinion

Overall, the benefits of Ansys AM far outweigh the drawbacks. Ansys Additive manufacturing software is a powerful tool that can help engineers design and simulate complex mechanical systems. It is also very user-friendly, despite the learning curve.

2. Autodesk Netfabb

Autodesk Netfabb is a powerful, industrial-grade 3D printing software that helps files get printed by automatically preparing, repairing, and optimizing them for output.

It provides users with various options for printing in different scales and resolution levels, supports STL, OBJ, and AMF file formats, and can even generate Gcode.

With its easy-to-use interface and comprehensive features, Autodesk Netfabb is an essential tool for anybody working with 3D printing.

Features

- Automatic file preparation: Autodesk Netfabb automatically prepares 3D printing files for output, including repairing, cleaning, and orienting them.

- Support for multiple file formats: The software supports STL, OBJ, and AMF file formats, as well as Gcode.

- Wide range of printing options: Autodesk Netfabb offers users a wide range of options for printing in different scales and resolution levels.

- Selective structures: Solid volumes may be filled with custom structures to produce distinctive material properties for your component.

- Optimization: It assures a maximal load capacity and reduces weight by automatically verifying and modifying lattice and skin elements

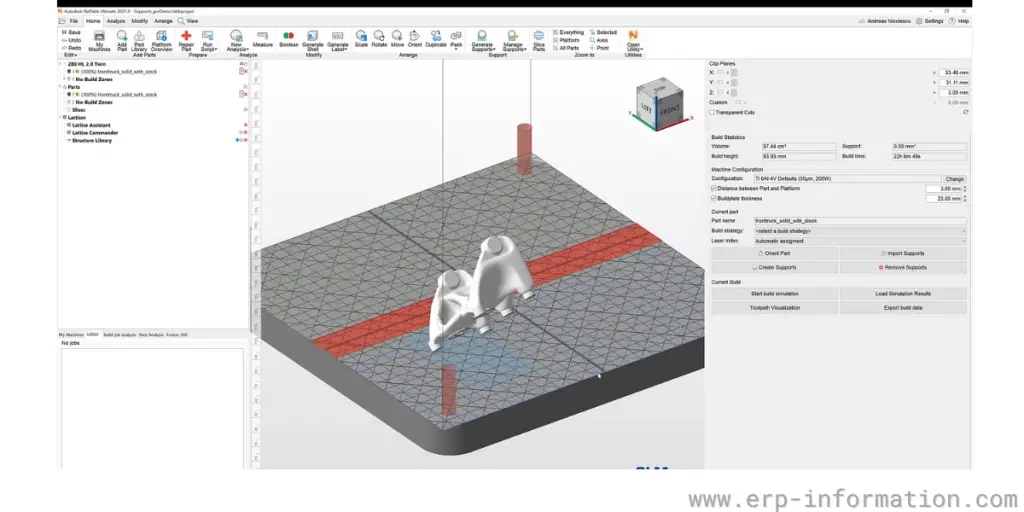

Screenshot of Autodesk Netfabb

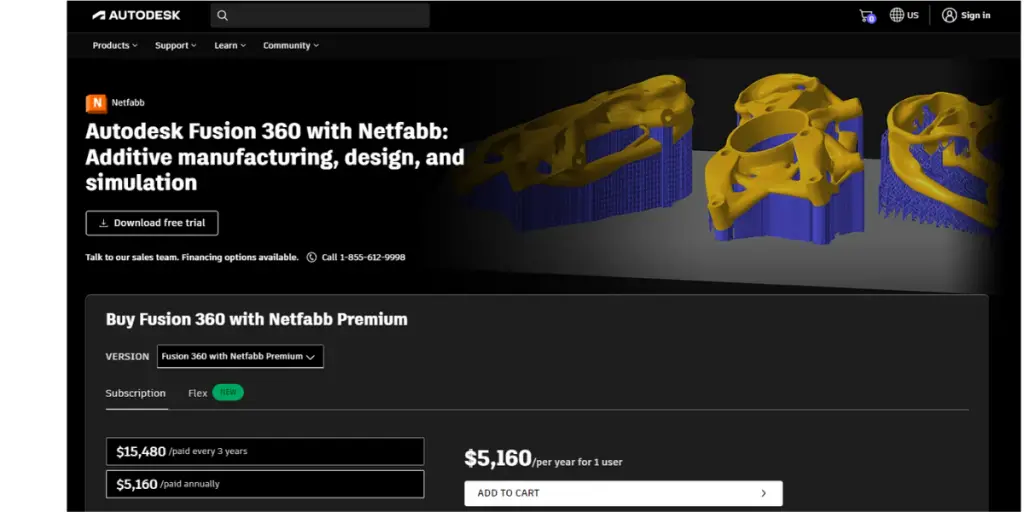

Pricing

Free trial: Available

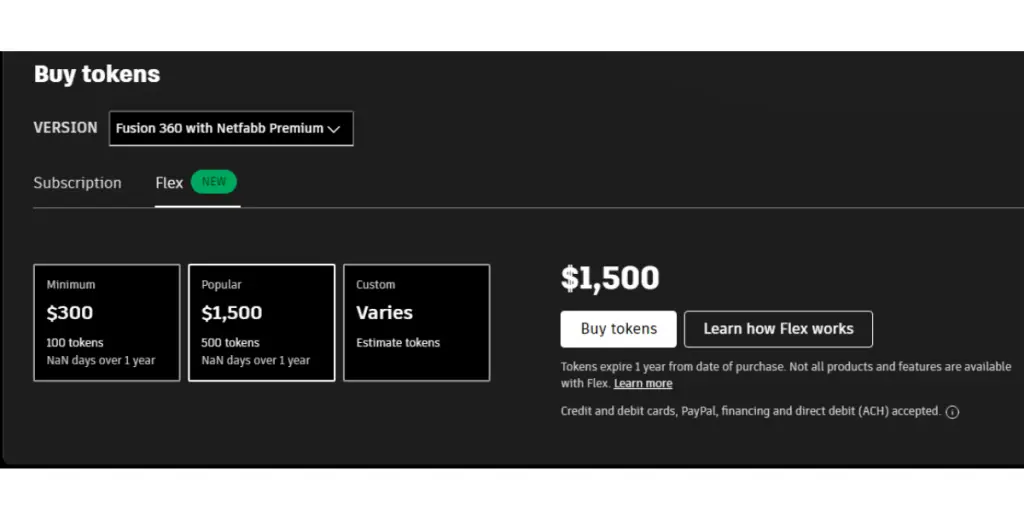

Netfab offers two types of pricing options; which are

Flex: It is a “pay as you go” offer if you only use the product occasionally. Here you are supposed to buy tokens for your team.

It offers three plans.

- Minimum – Charges $300 for 100 tokens over one year

- Popular – Charges $1500 for 500 tokens over one year

- Custom – Pricing varies depending on the token

Subscription: In the subscription plan, Fusion 360 with Netfabb Premium offers

- $5160 per year

- $15,480 per year

Likes

- Easier to use than other software programs.

- Allows for the repair of broken 3D prints.

- More affordable than some other software programs.

Dislikes

- Usage of RAM is high and occasionally causes lag in operation.

- File conversion can be difficult.

- Support from customer service can be spotty.

User opinion

Autodesk Netfabb is an excellent 3D printing software program. This program helps view and repair 3D designs and other essential activities. It is user-friendly, offers a wide range of printing options, and is more affordable than other software.

3. 3dSystems

It is a suite of software tools for designing and engineering parts for additive manufacturing (3D printing) on 3D Systems printers. It allows users to create and edit 3D models, slice them into layers for printing, and control the printing process.

Its ADII is a machine designed with 3D Systems’ additive manufacturing software. It can print parts in multiple colors and materials and has a build volume of 10x10x10 inches.

Features

- Rapid prototyping: helps users quickly design and prototype parts for additive manufacturing.

- Multi-material printing: 3D Systems’ additive manufacturing solution supports printing parts in multiple colors and materials.

- Connectivity: With an easily scalable, adaptable system, it adapts to rapid material and printing technology progress.

- Requirement-driven orientation: It orients your part to the build orientation that will minimize support material and build time.

- Direct metal printing: It offers outstanding build quality for direct metal printing with a broad range of alloys, metals, and plastics.

Pricing

The vendor does not provide pricing details; contact the vendor directly to get details.

Likes

- 3D Systems additive manufacturing software offers a stepping stone for medical device manufacturers to convert digital models into sterilized and ready-to-ship items.

- Its proprietary cleaning process has a record of high-performance applications delivering particle-free components.

- It’s an all-in-one program that allows you to design, print, and package products using different types of metals.

Dislikes

- Creating a structure can be time-consuming and difficult, owing to the need for high levels of design complexity and strict cleanliness standards.

Supported industries

- Academic and Research

- Aerospace and Defense

- Automotive

- Carbon capture

- Consumer technology

- Foundries

- Jewelry

- Motorsports

User opinion

3D Systems is a great company that offers an all-in-one program to design, print, and package products. However, the process of creating a structure can be time-consuming and difficult.

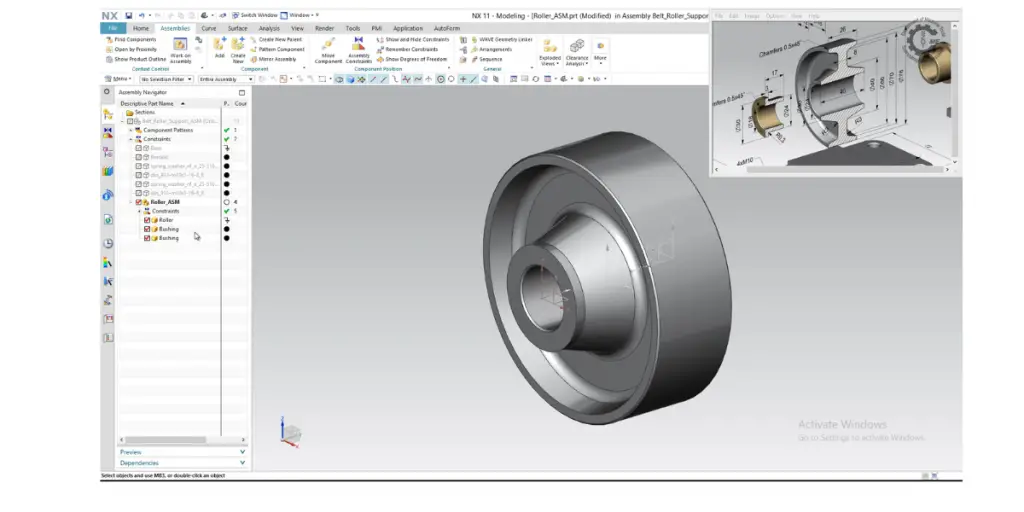

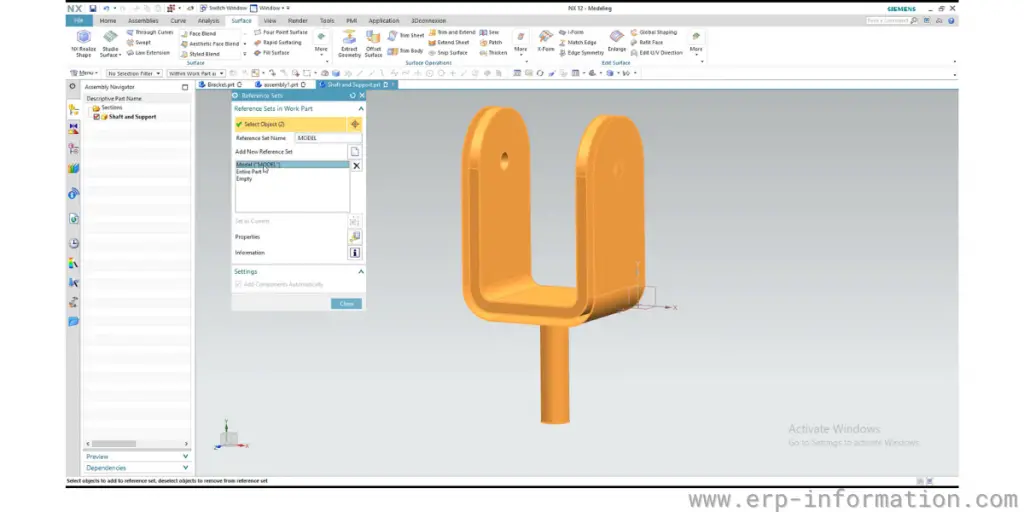

4. Siemens NX AM

The additive manufacturing software Siemens NX is a computer-aided design and manufacturing software that enables users to create, edit, and mill 3D models.

Companies can use the software in the aerospace, automotive, and medical industries.

Additionally, the Siemens NX system is equipped with powerful analysis tools, which makes it possible to verify designs before they are sent to production.

Features

- Integrated build tools: Siemens NX AM builds preparation tools assist with efficiently placing, orienting, and supporting components in the build tray.

- Structure validation: It allows the designer to check for printability and then simulate the part’s performance in the field using integrated tools to produce production-ready components.

- Quality and analytics: It allows you to keep track of the additive manufacturing process, examine the resulting data, and make improvements to parts and functions.

Screenshots of Siemens NX AM

Pricing

It provides a subscription plan or perceptual plan according to project requirements.

The subscription plan varies depending on your business module; it includes different versions of NX CAD and CAM tools for axis milling and turning, and each version offers different pricing options. The price varies between $174/month to $716/month.

Likes

- It is intuitive, user-friendly, and customizable.

- It also provides better tracking of who has parts open, who has signed in for each process, and the history of changes.

- Siemens NX CAD allows for more interactivity with users in the process’s downstream phases.

- It provides powerful 3D design and simulation capabilities.

- It offers an extensive library of standard materials.

Dislikes

- It is less suitable for small projects

- Needs improvements in revision control

- The learning curve is steep. Requires more time to learn the tool thoroughly.

- Licensing and Maintenance costs are high for small and medium-sized businesses.

- It needs specific hardware and software configuration requirements.

- Sometimes, the software becomes slow because of more consumption of RAM.

- Costly for small companies

- Not compatible with other software and systems that a company is already using.

- Require high-end hardware and system resources to run efficiently

Supported industries

- Marine

- Aerospace and design

- Automotive and Transportation

- Energy

- Electronics

User opinion

It’s fantastic for complicated and huge tasks like the auto or aerospace sector since it provides a suitable method of managing and controlling significant volumes of models. However, it is less suitable for small projects because of high licensing and maintenance costs.

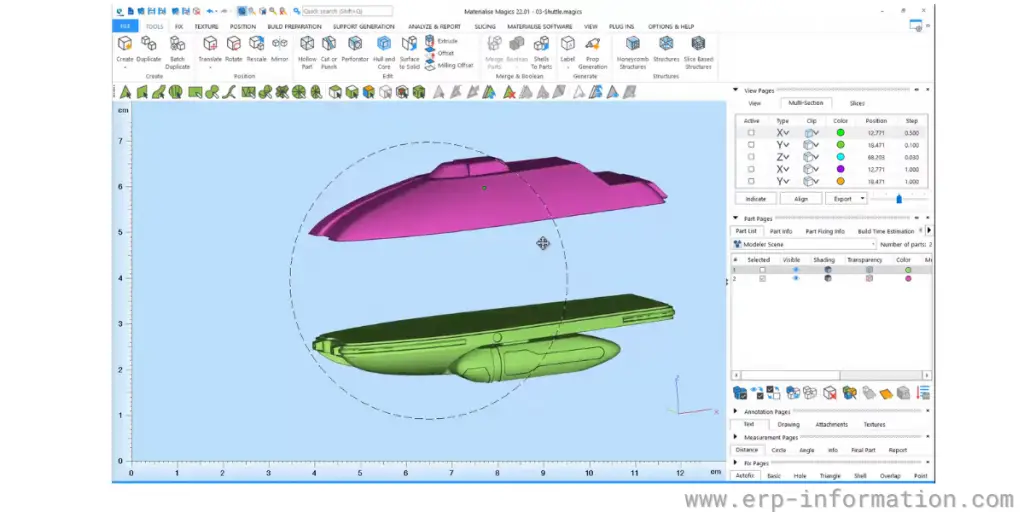

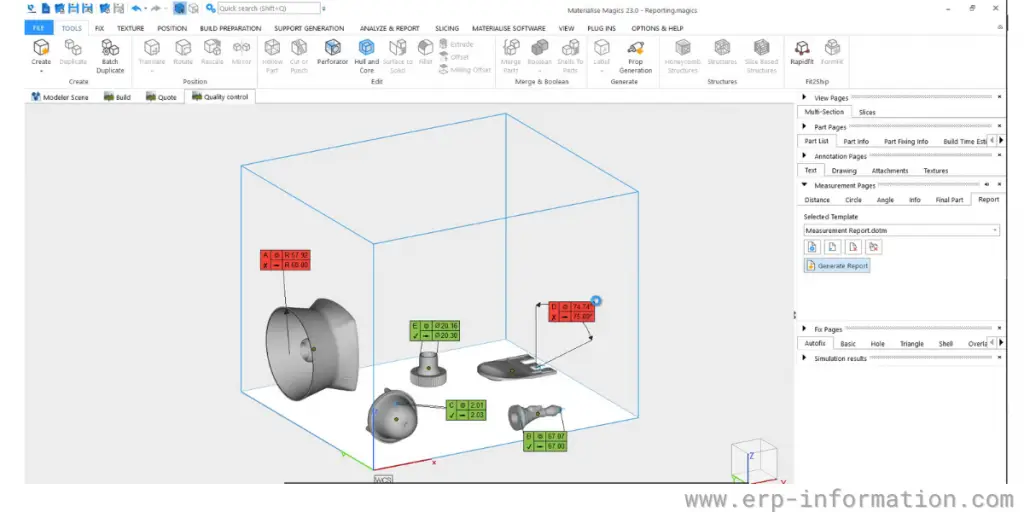

5. Materialise Magics

Additive manufacturing software Materialise Magics handles everything from design file preparation to slice determination to build planning and generator setup.

Most importantly, Magics ensures that your 3D-printed parts meet all the mechanical performance, accuracy, and surface finish requirements.

It offers unparalleled support for all the major 3D printing technologies and processes, including stereolithography (SLA), selective laser sintering (SLS), direct metal laser sintering (DMLS), and powder bed fusion (PBF).

Magic also supports various materials, from plastics and metals to ceramics, glass, and composites.

Features

- Quality management: It ensures that the components are printable and of good quality by adding features such as automatic fixing, offsets, and lattice structures.

- Seamless Transition: With precision, chop and orient the material with care and, Convey the information to the machine.

- Build analysis: Using analysis tools that discover potential problems may help avoid costly building failures.

Screenshots of Materialise Magics

Pricing

The vendor does not provide pricing details. Contact the vendor directly to get details.

Likes

- Highly customizable, as we may construct a lattice structure to reduce material usage and build a support system according to our needs.

- It provides a user-friendly GUI.

- The quick file and object recovery function is relatively fast and can quickly repair files or objects.

Dislikes

- The system becomes heated while working because of the high space requirement for RAM.

- Need improvements in integration with other software to export different file formats.

Supported industries

- 3D Printing

- Aerospace

- Automotive

- Eyewear

User opinion

It’s an excellent program, but it’s a little pricey. However, it needs improvements in integration with other systems. On the other hand, the ease of operation on Boolean and other cut paste is much simpler and happens flawlessly.

6. Solid Edge

Solid Edge is a complete product development portfolio by Seimens. It is easy to use, deploy and maintain and provides software tools for all aspects of the product development process, such as 3D design, simulation, manufacturing, and data management.

Features

- 3D design – It provides many capabilities, including synchronous technology, sheet metal design, modular plant design, CAD drawing, and assembly modeling&management.

- Electrical design – Designs and simulates electrical systems and analyzes models to calculate exact wire length

- Simulation – Provides capabilities like assembly design, digital validation, and finite element analysis.

- Data management – CAD data management solution enables you to secure and control your product data and process. Shares product information and collaborates.

- 3D printing – Design and 3D print your products.

- 2D drafting – Generates high-quality 2D drawings, simple drawing layouts, diagramming, and annotation.

- Computer-Aided Manufacturing – Allows manufacturers to use new manufacturing processes like CNC machining, nesting, cutting, bending, molding, etc.

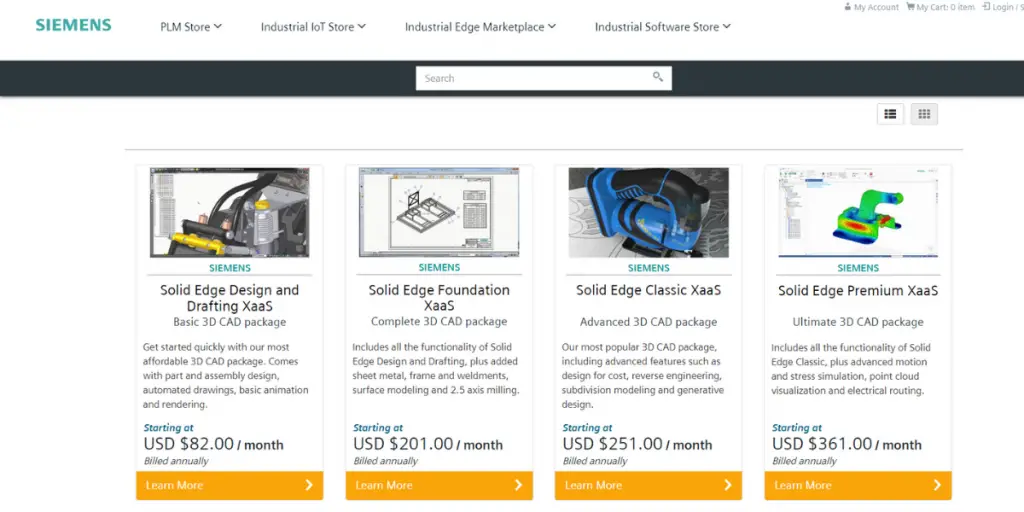

Pricing

It offers 4 plans

- The basic plan for design and drafting – Starting at $82/month per user (Billed annually)

- Solid Edge Foundation – Starting at $201/month per user (Billed annually)

- Solid Edge Classic – Starting at $251/month per user (Billed annually)

- Solid Edge Premium – Starting at $361/month per user (Billed annually)

Likes

- Flexible pricing plans

- A free trial is available

- Good support and training

- It is an advanced CAD software.

- Helpful for beginners with its simple interface and features.

DislikesSteep learning curve

- Software installation needs technical assistance.

- Unsatisfied customer support.

- Sometimes, unrecoverable errors occur.

- It takes time to open the software.

- Limited compatibility with other software.

- Steep learning curve.

- High cost of licensing and maintenance.

Supported industries

- Aerospace supply chain

- Automotive supply chain

- Consumer durables

- Industrial machinery

- Heavy equipment

Other details

| Deployment | Cloud, SaaS, Web-Based |

| Supported devices | Android, iPad |

| Support | Email/Help Desk, Phone Support, Chat |

| Training | In-person, Live Online, Webinars, Documentation |

| Languages Supported | Czech, German, English, French, Hungarian, Italian, Japanese, Korean, Polish, Portuguese, Russian, Spanish, Chinese |

User opinion

Solid Edge is an additive manufacturing software. It’s an incredibly user-friendly, cloud-based software with many great features that make it easy to create 3D models. It’s a top choice for anyone looking for great 3D CAD software.

7. Amphyon

It is especially known for metal additive manufacturing (LBM, SLM, DMLS, Metal 3D Printing). It is simulation-based process preparation software.

Features

- Examiner – optimizes applications based on analyzing and evaluating required support volume build time, surface accessibility, distortion sensitivity, and post-processing effort for every orientation.

- Supports – Creates optimized support structures.

- Mechanical process simulation – Calculates the residual stress and distortion fields on regular desktop hardware.

- Thermal process simulation – Calculates temperature history and field on regular desktop hardware.

- Predeformation – solution to pre-compensate residual distortions

- Integration with any brand of 3D printer

- Automates all the processes such as order, material, part import, orientation, support, nesting, and slicing,

Supported industries

- Aerospace

- Automotive

- Dental

- Medical

User opinion

Amphyon is a Metal additive manufacturing simulation software. It provides tools for 3D printing and computer-aided engineering(CAE). In addition, it offers MES capabilities and automates workflow.

8. Genoa 3d Simulation

This software provides many tools for additive manufacturing processes and metal applications. The software offers advantages to both machine operators seeking immediate parameter guidance and CAE analysts in search of comprehensive digital assessments of the thermal and structural aspects of their printed components.

Features

- Multi-scale material characterization

- FE model generation

- Thermal analysis

- Thermal structure analysis

- Build optimization

- In service qualifications

User opinion

Genoa 3D simulation software allows users to implement micro and macro voids into their process to do the virtual precision assembly. It also offers guidance on parameter settings and digital, thermal, and structural assessment of printed parts.

9. AdditiveLab

It is a metal additive manufacturing software and provides simulation technology that helps to predict metal-deposition AM processes. In addition, it offers complete access to all its features through a Python scripting interface.

Features

- Mechanical analysis

- Thermal analysis

- Customization of simulations

- Powder Bed Additive Manufacturing

- Direct Energy Deposition processes

- Scanning pattern analysis

- Melt pool analysis

User opinion

Its advanced simulation technology and simple user interface allow users to automate model preparation processes without simulation knowledge. In addition, it also reduces costs and increases productivity.

10. 3yourmind

3yourmind is AM workflow software solution that provides additive manufacturing strategies to many industries, including oil and gas, defense, aerospace, medical, automotive, railway, and machine&tooling.

Features

It provides 3 software suites.

1. Agile PLM

- CAD integration

- API integration

- Inventory analysis

- Centralized data storage

- Orientation optimization

- AM part identification

2. AgileERP

- Custom part requirements

- Accurate part pricing

- Business Analytics

- Automatic order management

- Material and technology comparison

- Distributed manufacturing networks

3. AgileMES

- Custom AM workflows

- Smart part priorotization

- Digital production planning

- Part sequence tracking

- Production sheet generation

- Quality assurance

- Machine connectivity

- DATA standardization

Other details

| Deployment | Cloud, SaaS, Web-Based |

| Supported devices | Android, iPad, iPhone |

| Support | Chat |

| Training | In-person, Live Online, Webinars, Documentation |

Supported industries

- Defense aerospace

- Energy

- Transportation railway

User opinion

The software enables users to define additive manufacturing workflow that matches the exact production and post-processes their company uses to manage AM production. It also provides machine connectivity with real-time input.

Can additive manufacturing software accommodate various 3D printers and materials?

Yes, additive manufacturing software is designed to support a wide range of 3D printers and materials, offering manufacturers flexibility to choose hardware and substances based on their specific production needs.

Can additive manufacturing software be integrated into existing manufacturing workflows?

Yes, additive manufacturing software is designed for seamless integration into existing workflows, enhancing efficiency and allowing manufacturers to leverage its benefits without major disruptions.

Conclusion

When selecting additive manufacturing software, it’s essential to consider your specific needs and requirements.

For instance, if you’re looking for software that can be used to create detailed models for medical implants or other high-precision applications, you’ll need something with the same editing capabilities.

On the other hand, if you’re interested in using additive manufacturing for prototyping or low-volume production, you may not need as many features. As a result, you can save money by choosing a less expensive solution.

Reference