In the business tech world, “islands of automation” are like separate islands of automated processes that don’t communicate with each other smoothly.

Business leaders and IT professionals need to understand these islands to keep things running smoothly.

In this article, we’ll look at the meaning, examples, and disadvantages of islands of automation. We will also provide tips to eliminate it and benefits.

Definition

Islands of automation is an automated subsystem not integrated with other systems/subsystems with which it interacts.

In other words, the islands of automation are a condition in which automation systems or technologies cannot communicate and are not integrated into another system.

In an automated system, process or operations takes place with the help of fewer human resources and special instruments and devices to check the manufacturing process.

Islands of Automation Examples

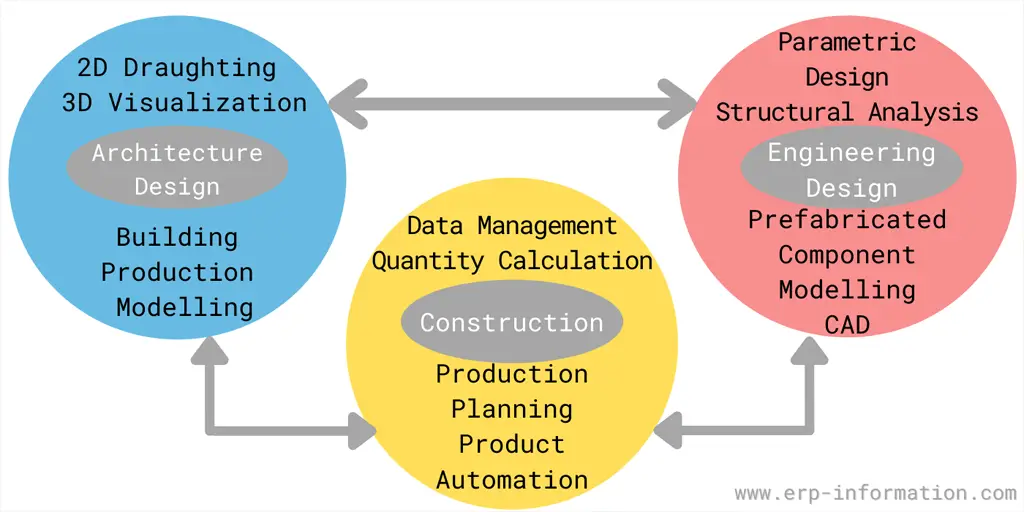

- Computer-Aided Design (CAD): It generates, modifies, and documents engineering designs. It is also used to analyze, optimize, and review the design.

- Computer-Aided Manufacture (CAM): This is a computer technology that helps in planning and controlling the manufacturing process.

- Computer Numeric Control Machines (CMC): These stores computer programs and processes basic numerical control functions.

- Automated Material Handling System (AMHS): It contains material handling instruments like trucks, conveyors, cranes, robots, monorails, etc., to transport and control materials.

- Computer-Aided Process Planning (CAPP): It is a systematic approach that leverages computer technology to assist in the planning and optimization of manufacturing processes. It involves the use of computer software and databases to generate detailed instructions for the production of components or products.

- Computer Control System (CCS): It is an integrated system of hardware and software components designed to manage and regulate the operation of various devices or processes through the use of computers. It enables precise monitoring, control, and automation of tasks, contributing to increased efficiency and accuracy in industrial, manufacturing, or organizational processes.

- Group Technology (GT): It is a manufacturing technique that centralizes the production of parts with shared geometry or functions, using a limited number of machines. The core principle is recognizing similarities among manufacturing problems, allowing for a unified solution and significant time and effort savings.

- Flexible Manufacturing System (FMS): It contains a set of process stations that are internally connected and handled by an integrated computer system.

Why do islands of automation happen?

Islands of automation happen due to an unsystematic IT planning and infrastructure approach. It also happens because of the unintegrated establishment of databases, systems & applications and the absence of coordination between internal departments.

Disadvantages of Islands of Automation

- In an organization procure-to-pay process has many steps. Unconnected systems for purchase order issues, approvals of order requisitions, and purchase approvals consume much more time. Not only time-consuming but also an absence of transparency, increasing errors for authorization also happen.

- The Order-cash flow process fulfills customer orders for goods or services. Lack of connection between the internal applications and communication with the customer leads to delayed service, uneven revenue, and an unsatisfied customer.

- All companies use human resource management systems. Managers, supervisors, and administrators use this system to analyze HR data like uses of resources, payroll data, skill management, training, etc. However, it is difficult to analyze if there is no integration between HR data.

- ERP and CRM systems of the company should connect adequately. However, connecting them is sometimes difficult because of the different versions and upgrade processes. Moreover, no integration between them leads to a mismatch of customer details like customer profiles, contact data, order details, discounts, etc.

How do We Solve Islands of Automation?

There are some ways to solve this problem by communicating the below scenarios.

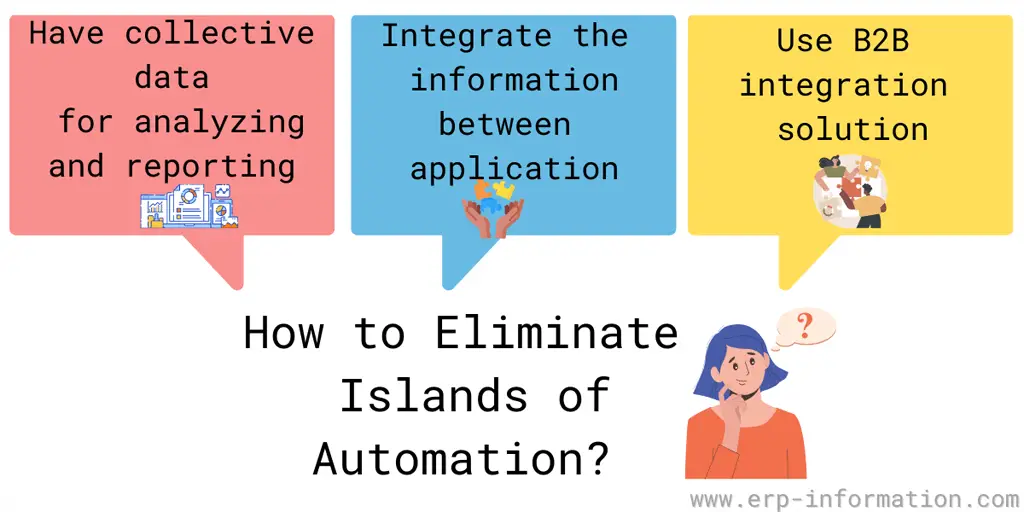

1. Collective data for analyzing and reporting

While analyzing data, the company must have collective data. For example, if you want to get purchasing costs, one of the best-integrated technologies, ETL (Extract, Transform, and Load), helps obtain aggregate data for analytics.

First, you need to extract the data from multiple sources. After that, you need to transform data into one structure and then load the data into the database.

This ETL system is one of the best solutions for islands of automation problems.

2. Integrate the information between applications

There will be a chance to present the same information in two separate applications. However, with the help of application integration technology, we can solve this problem.

3. Use a B2B integration solution

While interacting with external companies, you may face problems because of the lack of control and variations in data.

A business-to-business (B2B) integration solution helps overcome islands of automation by integrating the CRM, ERP, and financial system and automating the procure-to-pay cycle.

Benefits of Eliminating Islands of Automation

As the company grows, it uses multiple applications to perform its daily processes and fulfill its needs. That leads to islands of automation problems.

When it avoids or solves this problem, it gets the following advantages.

- Integrated systems help to avoid duplication of information.

- Saves time by avoiding entering the same information in different applications.

- It helps the employees develop their efficiency and skill as they learn only one application thoroughly instead of many.

- Increases productivity.

- Minimize the errors by avoiding manual entry.

- It helps to get complete and data-accurate reports quickly and easily.

What is ERP Automation?

ERP automation is the process of withdrawing manual interruption while doing tasks. Thus, it enhances the productivity and quality of the task by reducing errors.

In this way, ERP automation helps businesses give the solidness required for profitability.

ERP Automation benefits

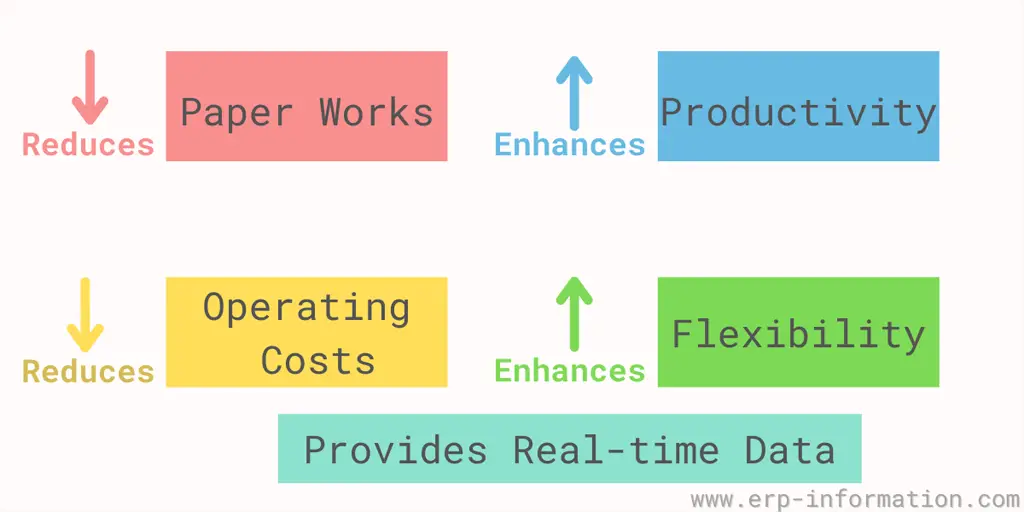

Reduces the paper works

While doing the business process, it files up more and more data daily. As a result, it is difficult to manage all data on paper, and there is a chance of missing information.

As a result, you will not get all the real-time records, leading to inaccuracy and inefficiency in the business process.

An automated ERP system helps reduce paper use and stores your business data well-structured with a secured server and centralized database. That enhances business management.

Provides real-time data for business process

You must go through all the files or documents to get specific information if you have your business data on paper. That takes a lot of time to collect accurate real-time data.

With automated ERP, you can easily find real-time data with one click. The computerized system goes through all the records and generates real-time reports to make decisions immediately.

Enhances resource productivity

An automated ERP system combines different business processes and reduces data errors. That leads to information uniformity between all the departments of the organization.

As a result, data redundancy is eliminated. Furthermore, any authorized person in the organization can access the data. Hence productivity increases automatically.

Improves flexibility

An automated ERP system records all the business information automatically. So, you can access the required data from any electronic device without restriction.

That improves flexibility in process management.

Reduces operating costs

ERP functionalities automate data entry. Hence you can reduce the investment in human resources.

Other than that, your organization will become more efficient and have reasonable control over expenses because of the automated business process. Hence reduces the cost and enhances the profit.

Conclusion

In an enterprise, the subsystem is critical for improving performance. However, it must be managed carefully because it can create islands of automation that are difficult to integrate with other systems.

When this happens, it can lead to decreased productivity and increased costs. In some cases, replacing the entire system may even be necessary.

This blog post has provided complete details of the Island of Automation, its examples, and its disadvantages.

Get more definitions about islands of automation and other ERP-related terms here.

Reference