Direct numerical control (DNC) is the process of controlling a machine tool or other device by sending it specific numerical commands to achieve the desired result.

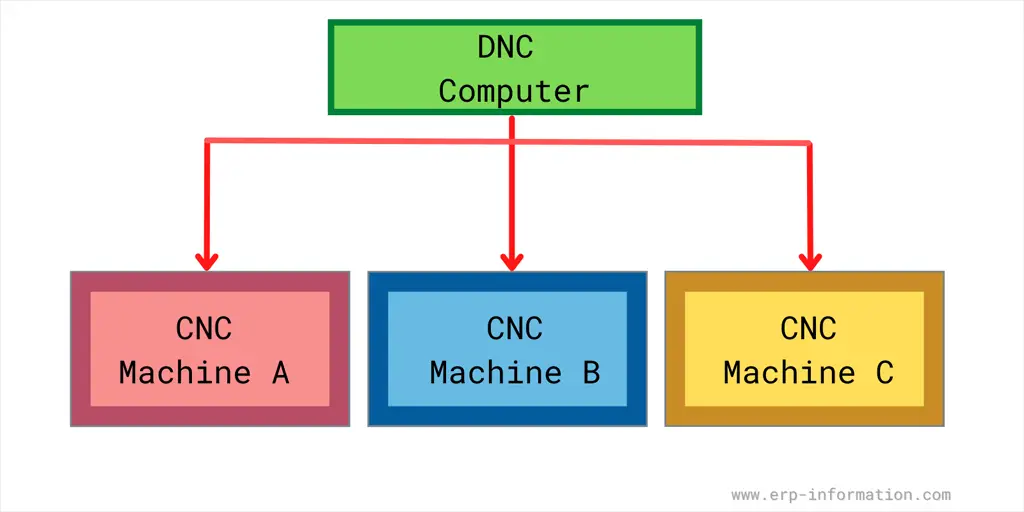

DNC systems typically send these commands from a computer located anywhere. This makes it possible to operate machines with unavailable on-site operators.

This blog post will explore the details of DNC systems and discuss some of their benefits. Stay tuned!

Definition

Direct numerical control (DNC) sends machine tool commands from a computer to a machine tool without requiring intermediate manual intervention. In addition, it enables unattended machining and provides process documentation.

The set of machines mentioned above uses computer numerical control (CNC).

Another name for it is Distributed Numerical Control.

What is computer numerical control (CNC)?

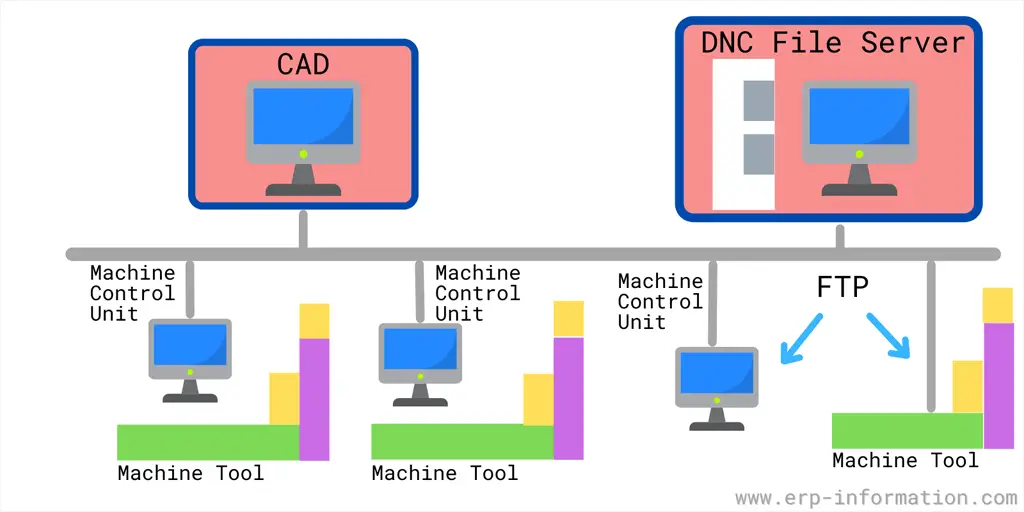

Originally designed to automate manufacturing, CNC is a system that controls the destination and action of a machine tool. The software involved with this process is CAD/CAM or Computer-Aided Design/Computer-Aided Manufacture, which develops the needed commands for these tools depending on calculations from programs such as Pro E.

For any machine to work, it has to be fed instructions on what materials need to be cut and where they need to go. Before, computers calculated these instructions manually or relied on time-consuming trial and error experiments. Still, they can generate computer code that gives accurate instructions every time without the worker wasting hours trying different combinations that may not even work.

It is based on real-time data and involves data collection from the machines and passing it to the mainframe. The operator will be in control of the mainframe computer through remote access.

A DNC will not contain a tape reader. Instead, several part programs are transferred to the machines from the computer memory.

The machine controllers will not store the entire program in a few scenarios because of the lack of memory space.

If the program is stored on a different computer, the directions can be sent directly to the machines.

The DNC is designed to provide separate instructions to every machine. Thus, when the machine immediately controls the command, they are sent across directly.

DNC Machine

What does a DNC machine contain?

DNC machines typically contain a mainframe computer used to store and retrieve information related to the manufacturing process. They also have a large memory capacity, allowing them to hold large amounts of data. In addition, they are connected to other machines and computers to share information and coordinate production. Finally, they contain machine tools used to create the final products. DNC machines play a vital role in modern manufacturing with their advanced capabilities.

Usually, only large organizations use them because smaller organizations can’t afford them due to higher costs.

Functions of Direct Numerical Control system

- The central computer stores and edits the programs for all machine tools connected to it.

- On a requirement basis, it gives the stored program to the connected machines.

- Having a shared database, it combines CAD with CAM.

- It links the central computer and plant computers connected through the network even though they are very far away.

Advantages

- Direct numerical control avoids the usage of punched taps and the reader from the system.

- It helps the business to understand production performance by getting several reports and valuable data from the machines.

- It helps in building a centralized control for the machines.

- Useful for time management and increased productivity.

- Convenient storage of part programs in several computer files.

- It helps the company to make higher-level decisions.

- It helps the business to increase its computational ability.

- It supports management information systems effectively.

Disadvantages

- It is costly, and it requires high automated areas

- Because of its central control system, if the computer fails, then all the activities of the machines would be stopped

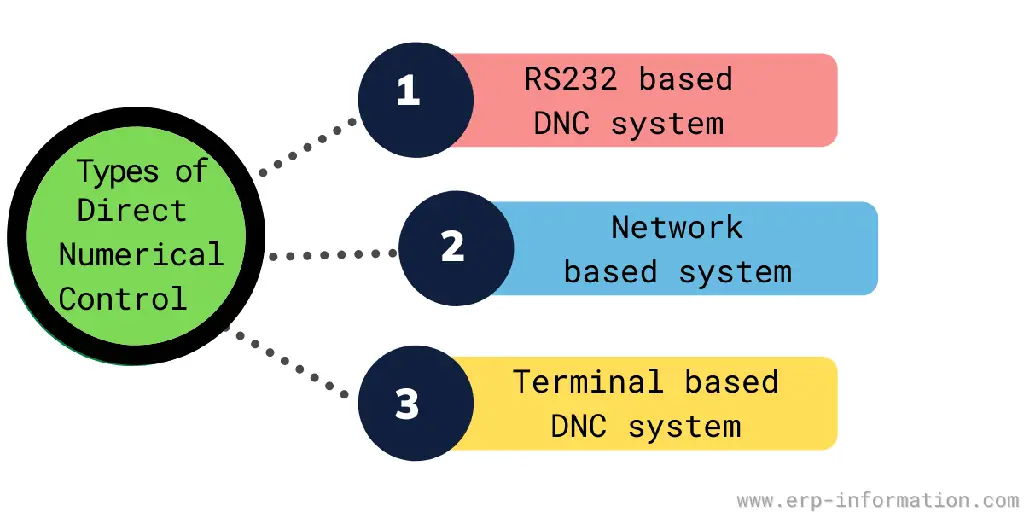

Types of direct numerical control

It can be divided into three types,

RS232 – based

Operates with a switch box or multi-port cable connections to connect several machines. It is used on older lathes, milling machines, and some Bridgeport-style mills.

Terminal-based

A CNC terminal is created to connect several programs. The main advantage of this system is that it’s easy to modify programs. In addition, the terminal enables the machine tool to be tested for accuracy before use.

Network-based

Direct access to NC programs without installing terminals and is thus highly efficient. It uses TCP/IP Direct Control Protocol (DCP) to quickly transfer programs to the machine tool.

Direct Numerical Control Software

Following are DNC software vendors

- NCnet

- Skytrends

- Antech microsystem private limited

- Next tech CNC private limited

- Niha solutions

- Technovision CNC

Uses of Direct Numerical Control Software

DNC software allows you to operate the system smoothly. Following are a few uses of it,

- Helps to control uploads and downloads remotely.

- Allows you to know the current status of machines.

- It allows you to take the maximum utilization of CNC systems and helps to keep on the total usage of CNC running.

- The software provides a Preset/Protocol editor that helps with quick adjustments.

- Provides industry-standard editor that helps to easy usage.

- It helps to improve the productivity of the operator.

- Removes or reduces machine downtime for program transfer.

- It avoids the mixing of programs.

- Increases productivity and efficiency by comparing the files automatically.

- Provides security by tracking and monitoring the changes to files.

- It provides easy access to graphical toolbars.

Differences between Direct Numerical Control and Computer Numerical Control

| DNC | CNC |

| We can control working operations with remotely. | We can not control working operations remotely. |

| Controls the information and manages the information distribution to more verities of computers. | Transfers machine instructions. |

| Can control more than one NC machine as per the requirements. | It controls only one NC machine. |

| It can be placed at a distance from machines because it is not an integral part. | It is an integral part of machines. |

| It has high processing power. | It has low processing power. |

| The maintenance cost of the machine is low. | The maintenance cost of the system is high. |

| It amplifies the capacity of the particular computing machine tool. | Controls the equipment and also acts as a management information system. |

The Future of Direct Numerical Control

Its future of it looks promising. New developments in wireless technology and the internet are becoming more accessible and easier for various applications.

It will continue to be used in manufacturing, and we can expect to see more and more such machines in one form and advanced IoT(Internet of Things) technology as time goes on.

FAQs

What industries commonly use DNC machines?

Industries such as aerospace, automotive, electronics, and general manufacturing extensively utilize DNC machines for their precision, efficiency, and ability to handle complex production tasks.

What are the key components of a DNC system?

A typical DNC system comprises a central computer, communication network (wired or wireless), machine tools with DNC interfaces, and DNC software for programming and monitoring.

How does Multi-DNC differ from other DNC machine types?

Multi-DNC systems allow for communication with a larger number of machine tools simultaneously, making them ideal for large-scale manufacturing environments requiring extensive coordination and control.

Conclusion

The DNC is a technique that uses numerical input to control the movement of machine tools. This technique is used for metal fabrication or woodworking, but it’s most often used in CNC machining.