Staying organized and efficient in the fast-paced world of production and manufacturing is crucial. That is where priority control comes into play.

By assigning priorities to different tasks based on urgency, importance, and resource constraints, businesses can minimize delays, streamline operations, and meet customer demands on time.

In this blog post, we will explore the concept of priority control and its significance in today’s dynamic production environments and will also discuss priority management.

What is Priority Control?

Priority control is the process of communicating start and completion dates to manufacturing departments to execute a plan.

The dispatch list is typically used to provide these dates and priorities based on all open orders’ current plan and status.

It is an essential aspect of manufacturing that ensures the highest-priority items are processed and completed first. This helps minimize delays and ensure that the most critical work is completed on time.

It is important to prioritize tasks in industrial and manufacturing settings to ensure that the most critical operations are carried out efficiently and correctly.

Priority Control is a system that helps managers and workers prioritize tasks by assigning a priority level to each process.

This allows workers to focus on the most critical tasks while completing all necessary tasks.

Now, we will understand the priority control with an example.

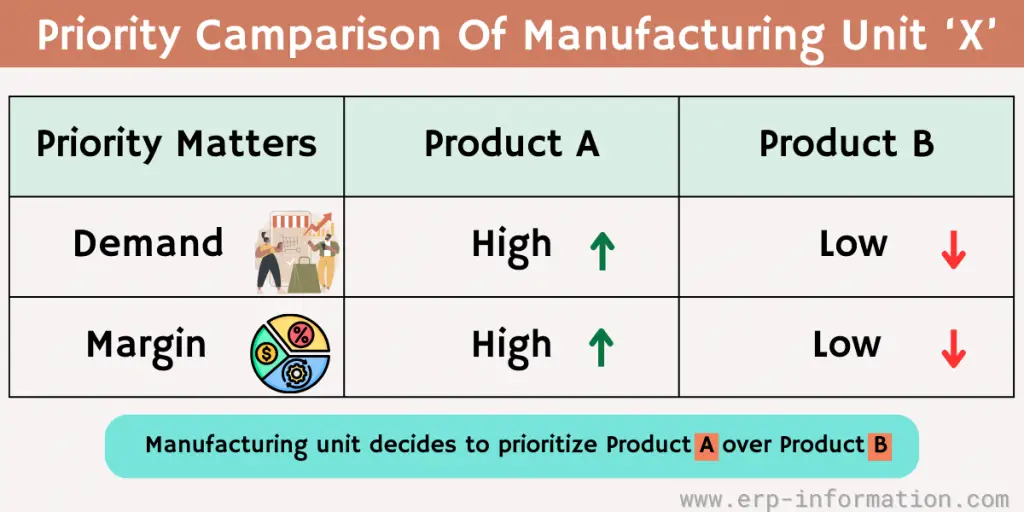

‘X’ manufacturing unit produces two products: Product A and Product B. Product A is a high-margin product in high demand, while Product B is a lower-margin product in lower demand.

The manufacturing unit does not have enough capacity to produce both products at the same rate. This means that the company must prioritize one product over the other.

The manufacturing unit decides to prioritize Product A over Product B. This means that the company will allocate more resources to the production of Product A and reduce the production of Product B.

By prioritizing Product A, the manufacturing unit will be able to increase its sales and profits. The company will also be able to meet the high demand for Product A and keep its customers satisfied.

Let us have a look at priority management.

What is Priority Management?

Priority management is giving attention to time and resources towards work, tasks, and projects. As a result, it may influence high-value projects, accounts, and future goals.

Follow the below steps for effective priority management.

- Define the business goals.

- Line up your team goals with the company’s business goal.

- Generate a standard process to do work.

Priority Management is the process of assessing and allocating resources to meet high-value goals and objectives within a firm.

Apart from standard components of strategic planning such as market penetration, product development, and quality control, Priority Management includes goal and objective setting, strategy development, and portfolio management.

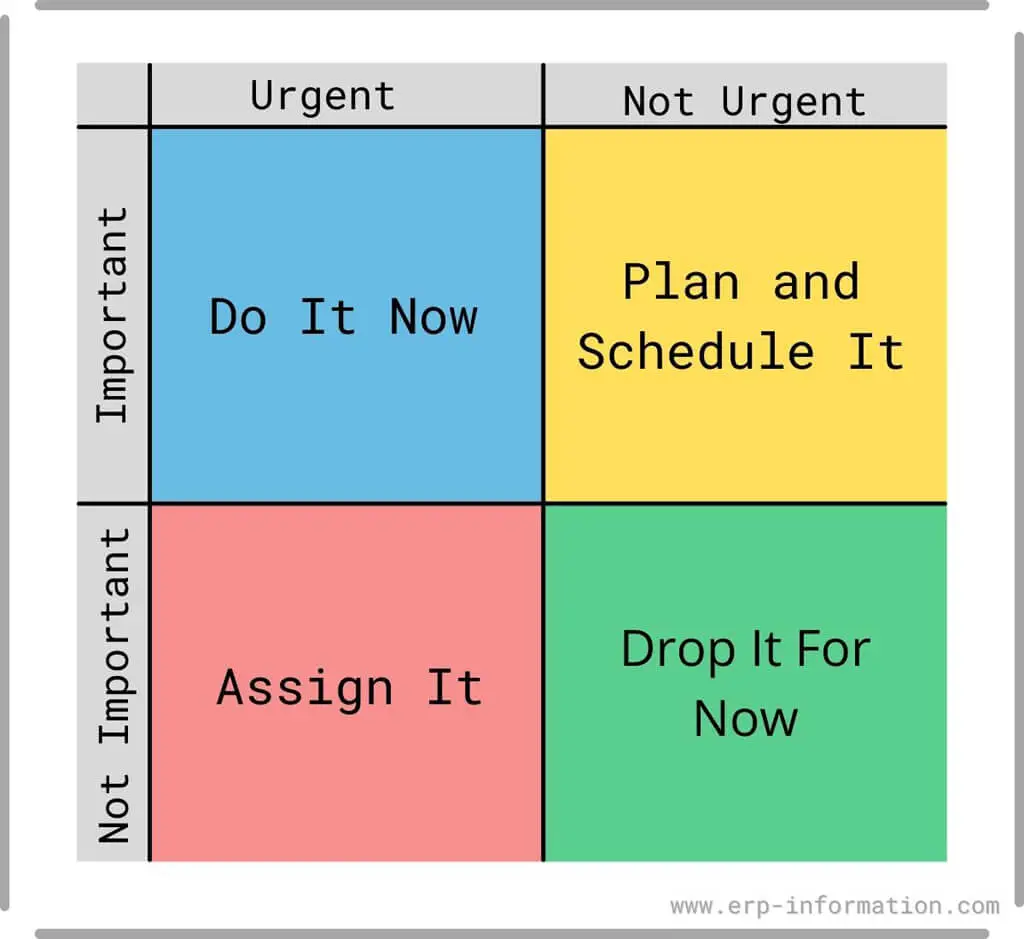

The basic premise involves defining the order in which tasks need to be completed (i.e., priorities), assigning them different scores for urgency, importance, or both, and finally tracking them against time set out over an allotted period.

Importance or Benefits of Priority Control

Priority control is important because it helps you to focus on the most important tasks and goals, and to make the best use of your time and resources. When you have effective priority control, you are less likely to feel overwhelmed, stressed, and overworked. You are also more likely to achieve your goals and objectives.

- Increased productivity: When you focus on the most important tasks, you can get more done in the same amount of time. This leads to increased productivity and efficiency.

- Improved time management: Priority control helps you to make the best use of your time by eliminating distractions and focusing on the most important tasks. This can lead to improved time management skills and less wasted time.

- Reduced stress: When you feel overwhelmed and overworked, it is difficult to focus and be productive. Priority control can help to reduce stress by helping you to focus on the most important tasks and to avoid taking on too much.

- Better decision-making: Priority control can help you to make better decisions by forcing you to think about what is most important and to weigh the costs and benefits of different options.

- Improved achievement: When you focus on your most important goals, you are more likely to achieve them. Priority control can help you stay on track and progress toward your goals.

Challenges of Priority Control

Priority control can be challenging for several reasons. Here are some of the most common challenges:

Identifying your priorities

The first challenge is identifying your most important priorities. This can be difficult, especially when you have a lot on your plate. It is important to take the time to think about your goals and objectives and to identify the tasks that are most important for achieving them.

Limited resources

It is often difficult to prioritize when you have limited resources, such as time, money, and people. It is important to make the most of your resources and focus on the tasks with the biggest impact.

Competing priorities

It is also common to have competing priorities. This can make it difficult to decide which tasks to focus on. It is important to weigh the costs and benefits of different options and choose the most important tasks for achieving your goals.

Changing priorities

Priorities can change over time. This can make it difficult to stay on track and achieve your goals. Reviewing your priorities regularly and making adjustments as needed is important.

Here are some tips for overcoming the challenges of priority control:

- Be clear about your goals: What do you want to achieve? Once you know your goal, you can start identifying the most important tasks.

- Break down large tasks into smaller ones: Large tasks can be daunting and overwhelming. Breaking them into smaller, more manageable tasks can make them seem less daunting and more achievable.

- Set deadlines for yourself: Deadlines can help you to stay on track and to avoid procrastination.

- Delegate tasks whenever possible: If you can delegate tasks, do it. This will free up your time to focus on the most important tasks.

- Take breaks: It is important to avoid burnout throughout the day. Get up and move around, or take a few minutes to relax and clear your head.

FAQs

What is Priority?

There is no simple answer to this question. The answer depends on the specific situation and the priorities of the person or organization involved. However, it is usually advisable to prioritize the most critical things and delay or postpone less urgent items.

One way to think about it is to consider what has the most significant impact on success. And yet another way to think about it is to consider what must be done first for other things to be done later.

What is a priority system?

A priority system ranks tasks based on their importance to efficiency.

A few general tips on creating a priority system can be helpful:

1. Start by identifying your most important goals and tasks. These should be at the top of your list, and you should focus on the daily.

2. Break down your larger goals into smaller tasks that can be completed efficiently and have a tangible end goal. This will help you stay focused and motivated when working on larger projects.

3. Make a schedule and stick to it as closely as possible to help you ensure that you are making progress.

What is priority planning in manufacturing?

In manufacturing, priority planning is a production scheduling method that gives higher-priority items precedence over lower-priority things, ensures that the essential items are produced first, and helps prevent bottlenecks in the production process.

One way to think of it is this: If you have a list of ten items, and item number one is a priority, then item number two would be the next priority, and so on. Priority planning allows manufacturers to plan for and produce the essential items to meet deadlines and meet their customers’ needs.

Conclusion

The process of manufacturing goods uses a variety of approaches. Priority Control is the ability to prioritize which orders are processed first to increase efficiency and output.

Manufacturing plants often use priority management systems but can also be used with other businesses or hospitals. This strategy saves time by ensuring that all customers get their products at an equal rate while still maintaining production-level goals without sacrificing quality for speediness.

In addition, with this type of system, you will have more overall capacity because each machine is producing only one part product per cycle instead of making multiple parts simultaneously on one device.