Have you ever wondered how businesses seamlessly manage their inventory and fulfill customer orders with precision? The answer lies in a powerful concept known as ‘Available to Promise’ or ATP.

ATP is essentially an inventory of what a company can able to offer customers in terms of products or services.

This blog post will go over the detailed definition and formula for ATP and some examples. Stay tuned!

Click here for Available to Promise Online Calculator

What is Available to Promise Inventory?

Availability to promise is a metric that measures the amount of product that a company can deliver to a customer shortly.

When a customer places an order with a company, they generally expect to receive their purchase on time. However, sometimes production delays or other issues can cause significant delivery delays.

To ensure that customers are not left disappointed, companies need to understand their availability to promise. This metric measures the amount of product a company can deliver to a customer shortly, and it is essential to ensure that customer expectations are met.

By monitoring availability to promise, companies can avoid overpromising and underdelivering, damaging customer relationships.

Available To Promise Formula

The formula for calculating Available to Promise is,

ATP = Quantity on hand + Total supply – Total demand

Here, quantity on hand means the number of readily available products.

Total supply means the number of products produced.

Total demand means the number of products that customers are ready to purchase.

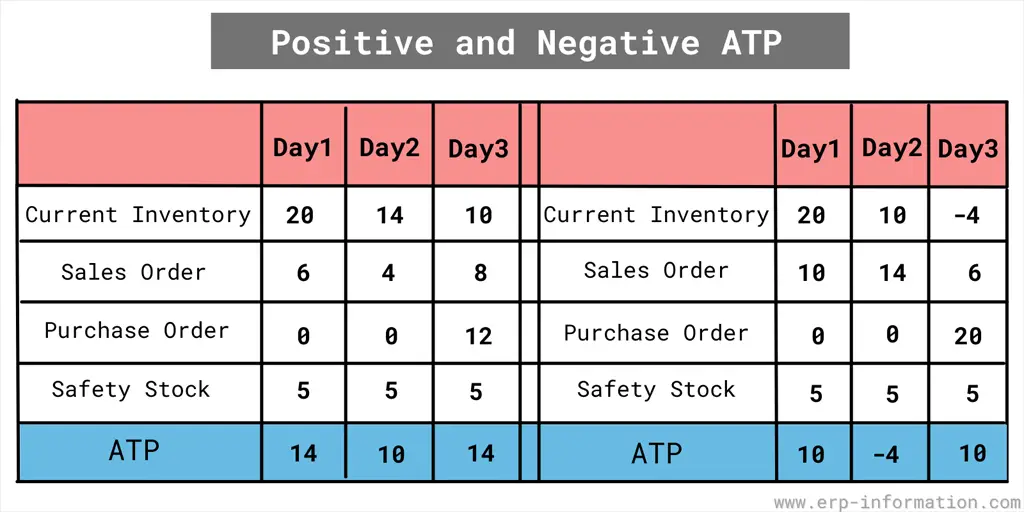

ATP can be positive or negative.

Factors that help to find ATP

- Current inventory: On-hand products that are readily available for urgent shipping

- Sales order: It is a report that upholds the sale. The vendor will issue this report to the customer before shipping the products to the customer’s place. The quantity of the product in the sales order is the amount committed to the customer even though it is in your stock.

- Purchase order(PO): The document created by the customer. When approved, it acts as an agreement between the customer & the vendor and is used to order the goods.

- Safety stock: It is the stock you need to hold to face the sudden demand and delayed inventory

Methods of Calculating ATP

There are three methods of calculation.

Discrete ATP

In this method, the calculation of ATP is based on its value in the primary schedule.

For example, the first period is the sum of starting inventory and MPS (Master Production Schedule) quantity minus backlog for all periods until the unit is scheduled again.

For other periods, the quantity has been scheduled for that specific period minus client commitments for this and different periods until the additional amount is planned in the MPS.

Cumulative ATP with a Look Ahead

The equation for calculating the production rate is the sum of ATP from the previous period and MPS of the period minus the backlog of the period.

The difference between the backlogs and MPSs of all future periods is also subtracted. This calculation is continued until production exceeds the backlog.

Cumulative ATP without Look Ahead

It is the sum of ATP in the previous period and the MPS minus the considered backlog. It will not be accurate if customer demand changes in the future.

Consequently, businesses should carefully monitor customer demand and adjust their production schedules accordingly.

Categories of Available To Promise

It is divided into two categories, Push and pull strategies.

Push ATP

A push strategy is nothing but real-time ATP. Here, the quantities and delivery due dates are derived based on the demand that has been forecasted. Then, the inventory and operation capacities are deduced based on regular production trends.

With appropriate scheduling, real-time ATP can be easily computed. Therefore, this is more favored than the pull strategy since pre-planning and preparing for unexpected production requirements.

The formula for the push strategy is

Push-based ATP = (On-Hand Inventory + Supply) – (Sales Orders + Forecasted Demand)

- On-hand inventory: Currently available products

- Supply: Purchase order, planned order

- Demand: Demand forecast and sales orders

Pull ATP

In a pull strategy, the company only produces what it has been ordered to make by the customer and not before.

Pull strategy does not consider forecasts. Hence, this method suits start-ups because they will not manage excess inventories.

The formula for the pull strategy is the same as the push strategy, with a slight difference.

Pull-Based ATP = (On-Hand Inventory + Supply) – Sales Orders

- On-hand inventory: Currently available products

- Supply: Purchase order, planned order

- Demand: Sales orders only

How is ATP Useful?

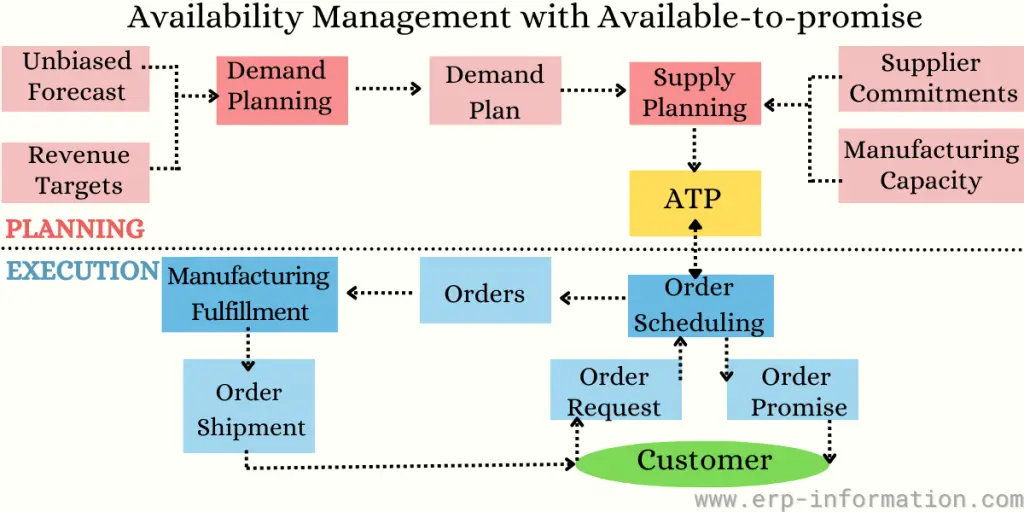

When this process is automated with efficient ERP systems, it helps to analyze the customer demands and adjust the required production schedules accordingly.

It even assists the customers to easily understand when they can expect the delivery for the orders placed.

Best Practices for ATP Inventory

For smooth flow of the process, follow the below steps

Have an efficient inventory management system

Implement the best inventory management software and ensure that it will allow you to take reports, maintain lean inventory, and forecast production schedules.

While enlisting, include suitable persons

Communicate its importance with all the team members and let them know how it influences them. Give a chance to inventory planners, customer service team members, supply chain leaders, and warehouse managers to suggest input during the ATP enlisting process.

Get confidence with the demo

Take your own time to understand the process until your team gets confident. Make sure there will be no overload of staff.

Available to Promise vs Safety Stock with Example

Consider a tech gadget store that has 100 smartphones in stock. They receive orders for 50 smartphones. The Available to Promise quantity, in this scenario, is the remaining 50 smartphones that the store can promise to new customers without affecting the fulfillment of existing orders.

The store maintains a Safety Stock of 20 additional smartphones to guard against potential stockouts.

This reserve ensures they can meet customer demands even if the expected supply chain.

Note: You can calculate your safety stock using our free online calculators. Check the list below

FAQs

What is the difference between available to promise and capable to promise?

ATP thinks about material availability, but capable to promise (CTP) is about fulfilling what you’ve already committed.

For example, suppose we know that a particular type of metal is becoming increasingly scarce and will likely be unavailable soon. In that case, we could commit to using less of that metal in our products.

Alternatively, if there is an alternate available material but slightly more expensive, we might promise to use that instead.

Are available to promise and safety stock the same?

No. safety stock is the minimum number of products that must be maintained in case of delay when unexpected orders come.

Available-to-promise refers to extra retained inventory necessary for delays, but it can also mean an amount below safety stocks, depending on how much you have.

A positive value means more items are needed, while a negative indicates less than desired amounts, which would cause shortages if not dealt with immediately.

Conclusion

ATP can help your organization better understand customer demand, improve supplier relations, and make more informed decisions about inventory.

While it is not a silver bullet for solving all supply chain problems, it can be a valuable tool in your arsenal.