Running a business requires effective and efficient tracking of projects, products, supplies, and more, especially regarding inventory. One key component of keeping your warehouse in order is Lot Tracking.

In this blog post, we’ll discuss what is lot tracking, its importance, benefits, the difference between lot tracking and serial tracking, and available software so that you can keep your business running smoothly with full product visibility across all sites.

What is Lot Tracking?

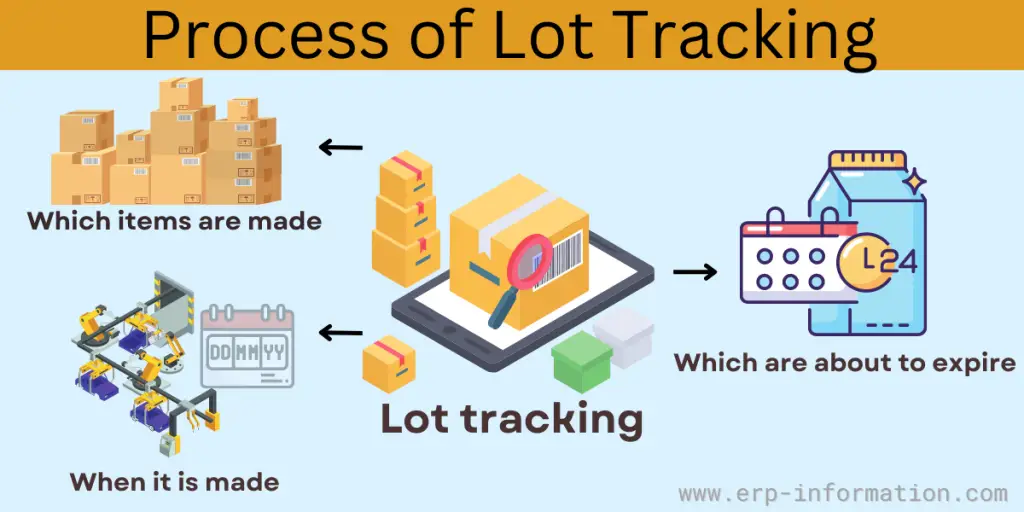

Lot tracking is a system that helps companies trace parts or ingredients used in products. It also helps them track which items are made, when, and which are about to expire.

It is also called batch tracking. This system tracks the products and materials from manufacturing to end-user stages.

It is helpful for organizing stock based on batches or lots for easy control, visibility, and traceability. When done correctly, batch tracking helps you stay organized and reduce losses from mismanagement or theft while providing information such as shelf life dates so that unsellable items don’t go unnoticed.

Needs of Lot Tracking

Lot tracking can help with many products but costs more because each lot needs space. However, it is very important for some perishable products like food and beverages, vitamins and supplements, electronic devices, medicines, cosmetics, etc.

It’s also very important for getting certifications from the Food and Drug Administration (FDA), ISO, CFIA, and BIO. It helps you trace where your product came from to make sure it’s organic and when is the expiry date.

Importance

Helps businesses stay open

It helps businesses stay open and respond quickly to changes. It also helps them when something goes wrong, like a product recall or warning. This can help prevent bad things from happening.

Efficient inventory management

Lot tracking is important to keep track of your warehouse inventory. It helps you ensure everything is in the right place and orders are filled correctly. Because of lot tracking, the following processes, such as

- Fulfillment of the products based on the expiration date

- Inventory scanning

- Fulfillment of distribution centers

become easier and help to manage inventories efficiently.

First in, first out system

Having lot tracking and FIFO processes in place can help ensure your business does not accidentally ship out expired products. This will protect you from bad reviews, complaints, and lawsuits for selling old items.

Product certification

Products that can spoil or expire need to be tracked. Batch tracking is very important for companies that want certification from the FDA, ISO, or CFIA. It’s also important to trace where the product came from to be labeled “organic.”

Human error elimination

Lot tracking is a system that helps you make sure you send the right items. It stops you from sending expired items by mistake. You can use software to set up lot tracking, making tracking your inventory and audits easier.

Provides a report of the returned product

Do you see many of the same products returned? When you get reports from your warehouse telling you products are returning from customers. That time, lot tracking helps you determine why customers returning things and which batch they come from.

Main users

- Food, drinks, and nutrition companies/any perishable product producers

- Cosmetics companies

- Medicines manufacturers

- Pet food manufacturers

- Hazardous products manufacturing companies

Difference Between Lot Tracking and Serial Tracking

| Lot Tracking | Serial Tracking |

| It is for bulk products. | It is for a single product. |

| It means tracking of how many items a company had when they were made and when they went bad. | Serial tracking follows a single product in each batch. This helps to track it during warranty claims or after it has been sold. |

| Examples: Food, medicine, fabric, etc. | Examples: Insurance, vehicle parts, electronic appliances, car parts, etc. |

Lot Tracking Software

Many software is available in the market to manage and track the products.

This software helps companies get information quickly about a group of products or a shipment. This is important if the company needs to do a product recall.

Different types of software can help you keep track of lot numbers. Each one has different features that let you control the lot numbers.

- Distribution accounting software: Distribution accounting software can help determine how much it costs for each group of items. Lot control is used to do this.

- Manufacturing and resource planning software: Manufacturing and resource planning software helps you plan production runs using lot numbers.

- Inventory management software: Inventory management software can keep track of items that come in and go out. It uses special numbers called lot numbers to do this.

- Warehouse management software: Warehouse management can keep track of items that come in and go out, just like inventory management software. But with warehouse management software, lot numbers can be used to determine where the items should be placed and which will go into order.

- Manufacturing execution software: Manufacturing and execution software can help you ensure that the ingredients you use to make a product are correct.

Below are some food traceability software with Lot Tracking

- ERPAG

- Acctivate inventory management

- Food connex

- Document compliance network

- Monitor Business system

- Recipe cost calculator

- Batch master ERP

- Produce pro software

Benefits of Lot Tracking and Traceability

- Reduces waste

- It makes sure that the supply chain stays legal

- Increases efficiency

- FDA certification

- Helps to make better business decisions

- Inbound and outbound quality testing

- Safety in manufacturing

- It offers specialized functionality

- FIFO and FEFO methodology for better stock management

One major drawback is it may not be useful for small businesses.

What is Serial tracking?

Serial Number Tracking is a way to track single items that your company makes and sells. Each item will be individually tracked from the manufacturing stage to the sale. Individual units will have a special number so you can tell which one you sold to each customer.

Conclusion

Lot tracking software has come to the fore in recent years, offering businesses and organizations greater insights and visibility into their supply chains.

This software gives businesses the tools necessary to automate inventory tracking processes while ensuring product compliance, accuracy, and reliability.

Overall, lot tracking and lot traceability are invaluable components of any successful supply chain operation.