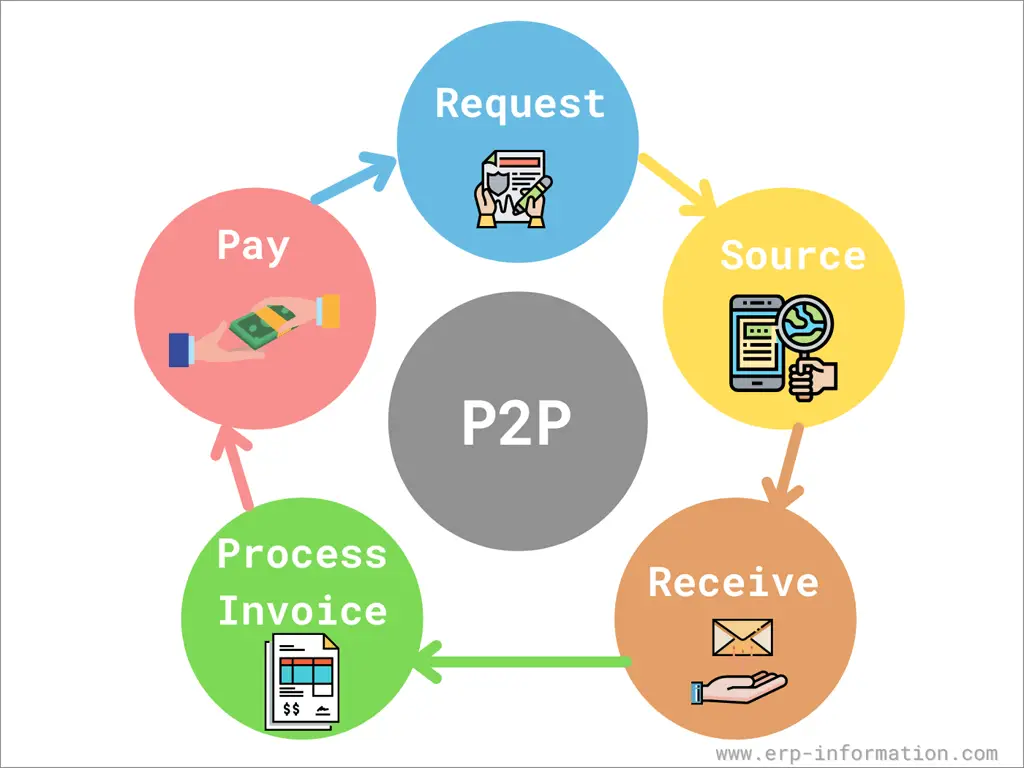

The P2P cycle, also known as the procure-to-pay process, is a key business function in SAP and other ERP systems. It covers the entire process of acquiring goods and services from suppliers and paying for them.

This process begins with requisitioning goods or services and paying the supplier for those goods or services.

This article discusses the 12 steps of the P2P cycle in SAP in detail. It also discusses p2p procedure, advantages, challenges, and more.

Check our other articles on the p2p cycle.

Video Introduction

Steps of the P2P cycle

The P2P cycle SAP MM is taken as a reference in this post.

You can find the 12 steps of the SAP Procure-To-Pay Cycle details below.

The following infographic provides an overview of the steps involved in this procure-to-pay life cycle.

The Procure-to-Pay or P2P cycle process starts when a buyer needs some goods or services.

1. Requirement identification & purchase requisition

The first step in the p2p cycle is requirement identification. That happens whenever a shortage of raw materials, services, or other parts is needed to continue the operation.

The production department communicates with the stores’ department for the needed materials. If it is in stock, there is no need to raise the requisition.

However, if the stock is unavailable, the person responsible for this in the store’s department will create a purchase request internally and send it to the purchasing department.

The person responsible will submit the purchase request to the purchasing manager. Here accounts department does not come into the picture.

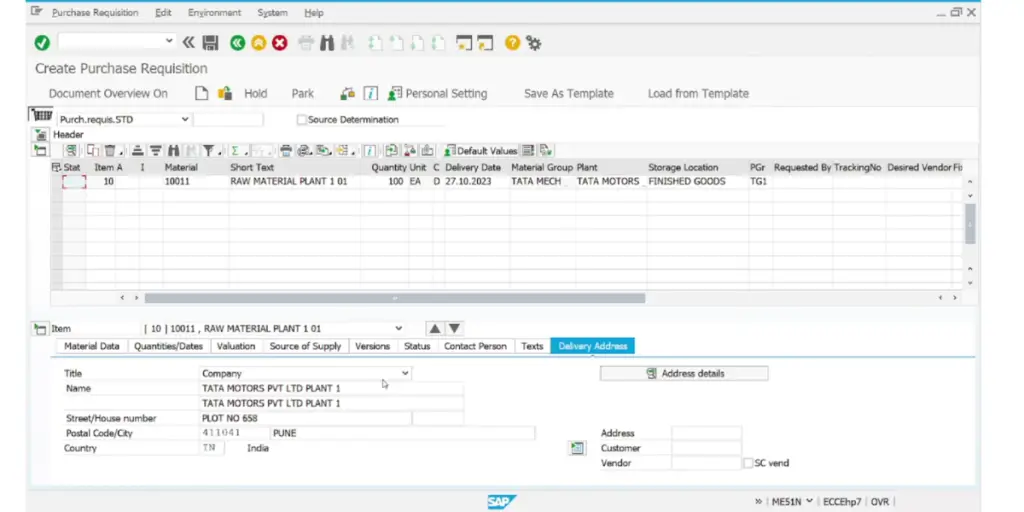

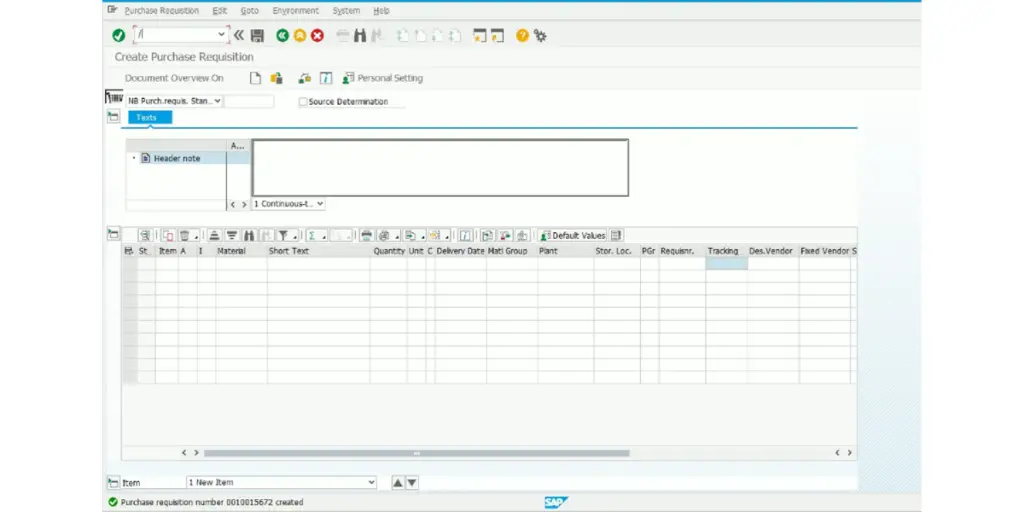

T-code for purchase requisition – ME51N

Below one is the created purchase requisition.

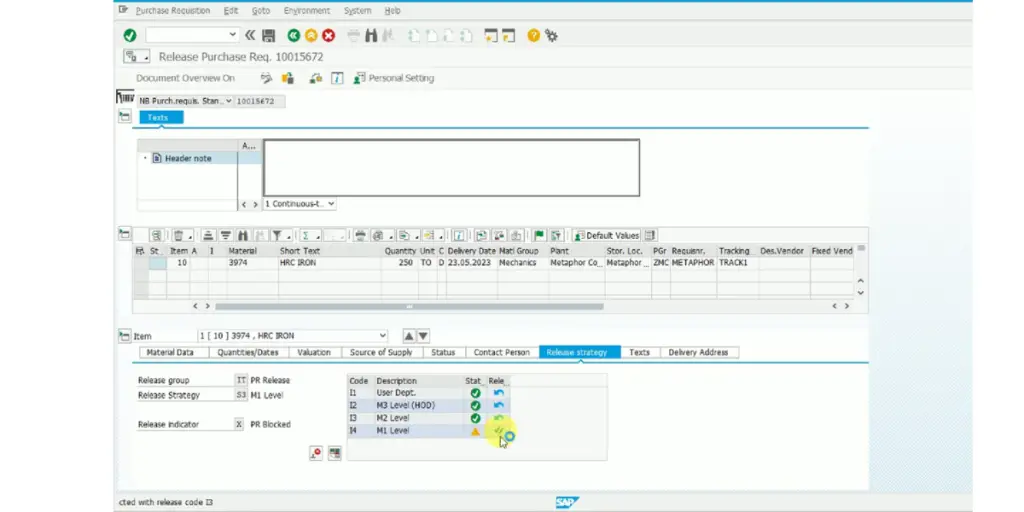

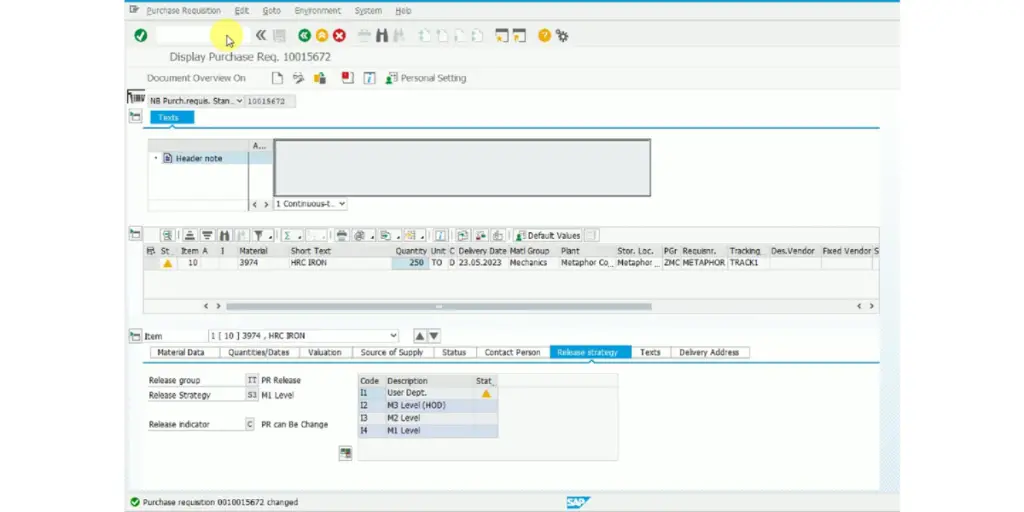

2. Authorizing the purchase requisition

The purchasing manager evaluates the purchase requisition and negotiates with different vendors. Here the purchase requisition can either be approved or rejected.

T-code for releasing purchase requisition – ME54N

T-code for purchase requisition display – ME53N

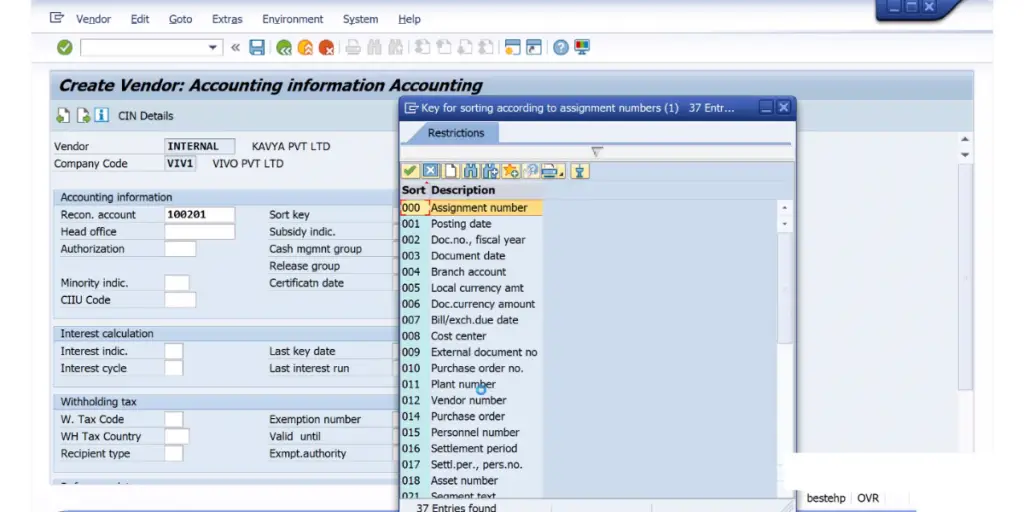

3. Shortlisting the vendors

Depending on the type of request, the procurement department will shortlist either a new list of vendors or the procurement department may directly approach the existing vendor for the material.

Vendor shortlisting depends on credibility, vendor rating, quality of the product or service, and pricing.

4. Taking quotations from the vendors

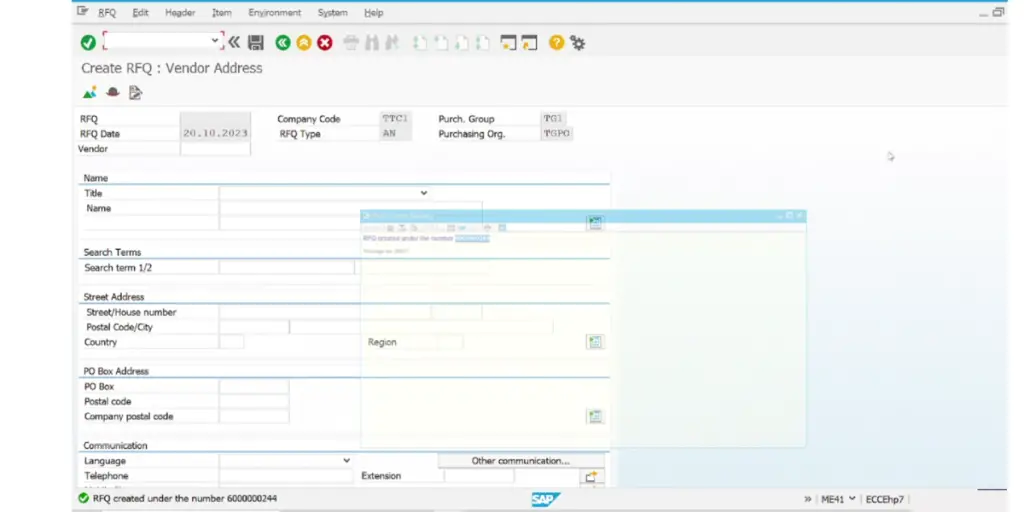

Here the buyer sends RFPs to all the shortlisted vendors to explain the requirements. The vendors are then asked to give their quotations.

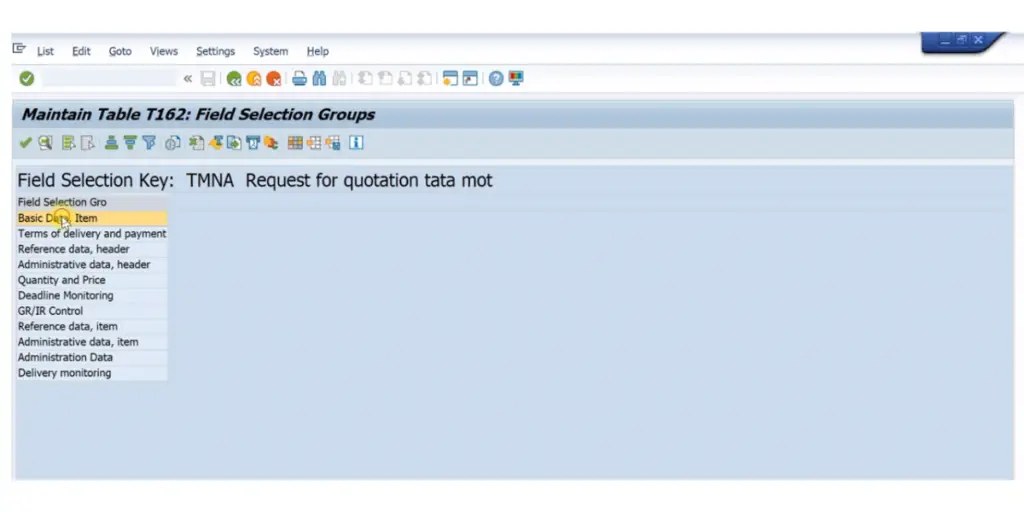

T-code for creating the request for quotation – ME41

5. Vendor selection

The RFP response is evaluated, and the vendors negotiate terms and quotations.

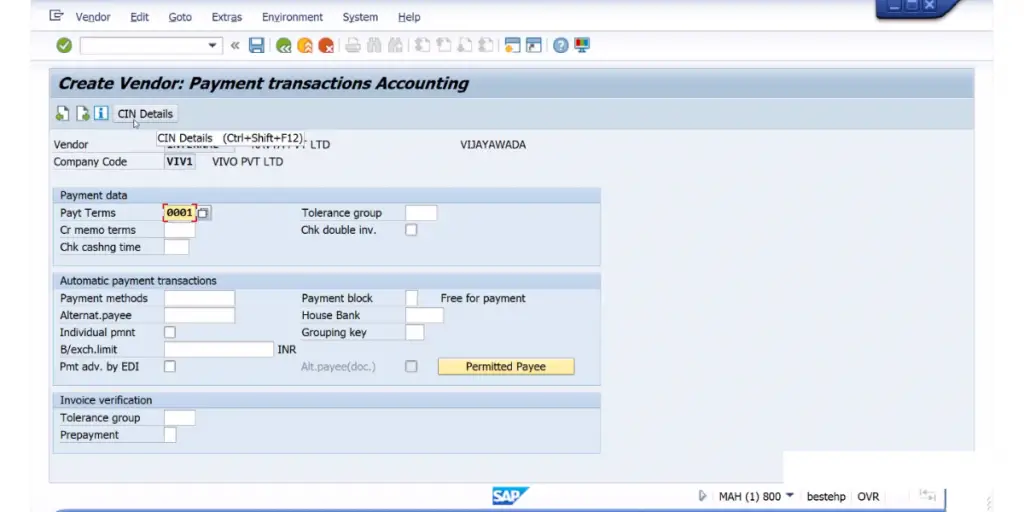

The agreement will be signed for the vendor whose quotation and the buyer accepts terms are shortlisted.

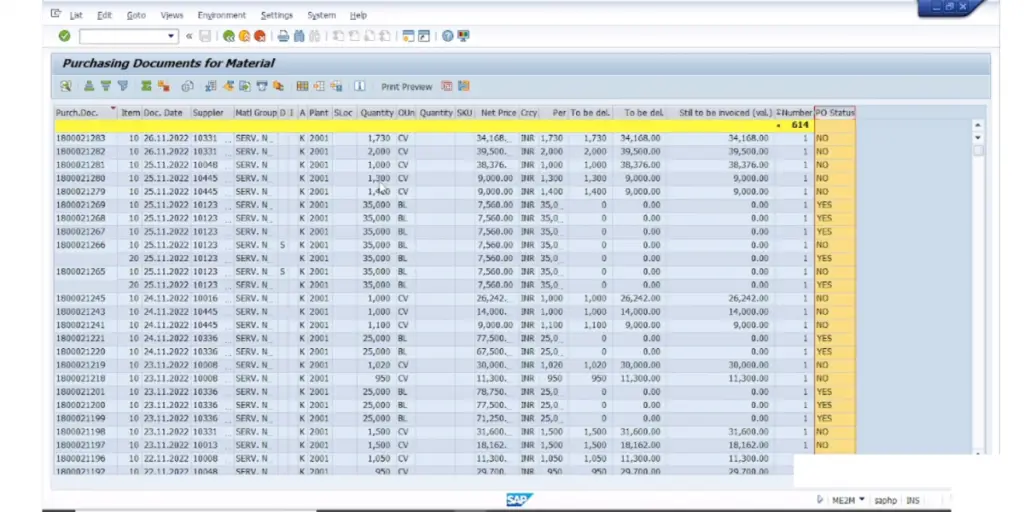

6. Creation of purchase order

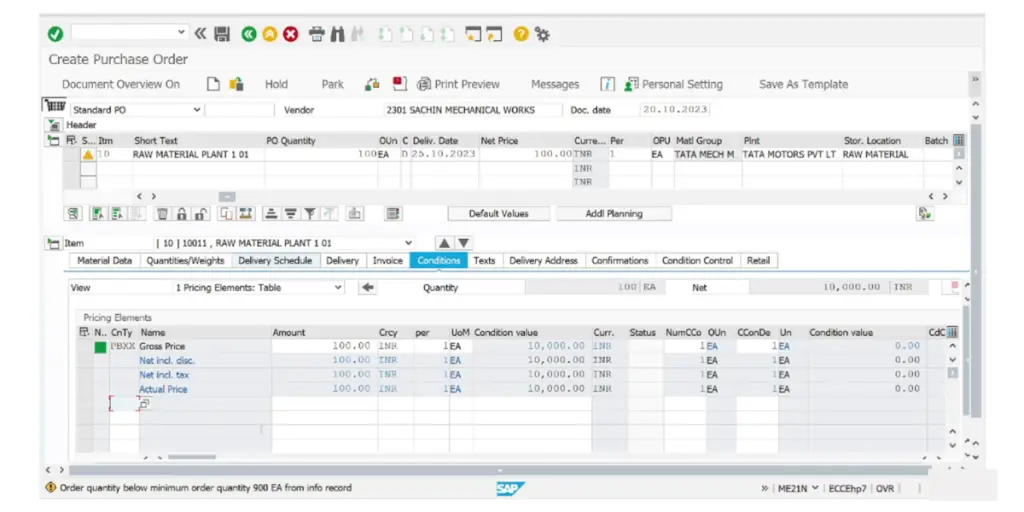

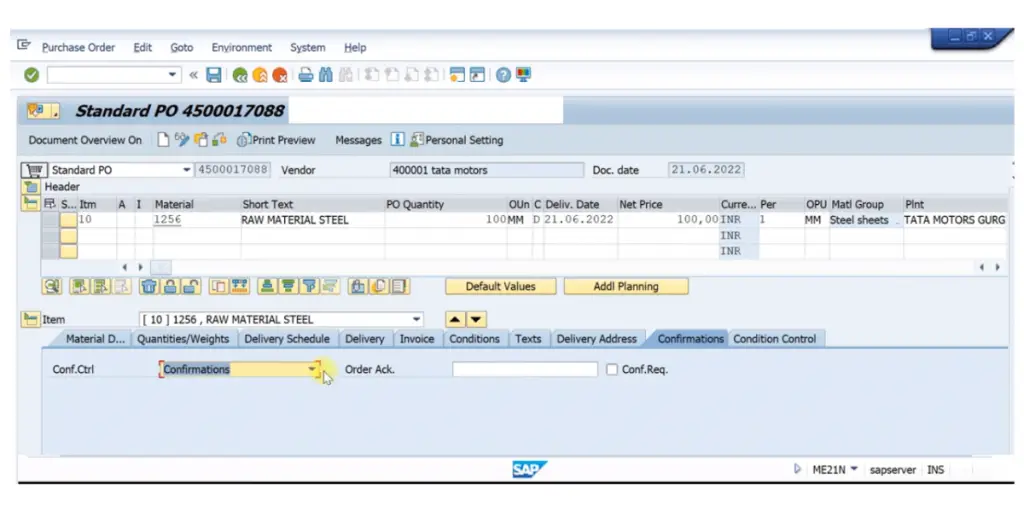

Once the purchase requisition is approved, the purchasing department finalizes the vendor depending on the importance and cost of the material or service and raises the purchase order.

Finally, the purchase order will be created, and the purchase manager will approve the PO and send it to the vendor with details like material description, price, quantity, payment terms, etc.

There will be different kinds of POs like Standard (Stock) PO, Service PO, Capex PO (Capital expenditure Purchase order), Opex PO (Operational expenditure purchase order), Consumption PO, Scheduled agreement, and Stock Transport (STO)Purchase orders.

T-code for purchase order creation – ME21N

7. Shipment notice

Once the agreement is signed, and the PO is confirmed, the vendor sends the shipment notification to the buyer. Notice informing about the goods or services that they are providing.

At this point, we are halfway through the procure-to-pay cycle. The shipment notice includes all the details, like a description of the goods and the shipment date.

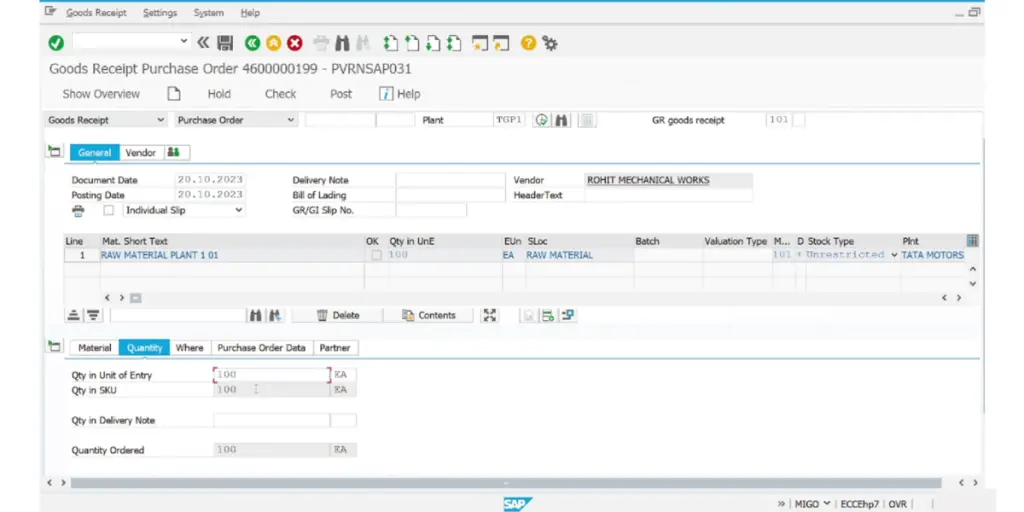

8. Receiving the goods/Goods receipt

The company receives the goods from the supplier. The materials or services obtained are inspected to check the quality and quantity of the materials. Goods receipt will be raised against the PO.

The delivery team compares the PO with the shipment notice to validate if the two match. If they match, the company issues the goods receipt to the vendor.

However, if there are discrepancies, the company can contact the vendor and ask for a refund or replacement.

In this stage, the system generates two reports. One is the material document in MM, and another is the accounting document in FI.

T-code for goods receipt purchase order – MIGO

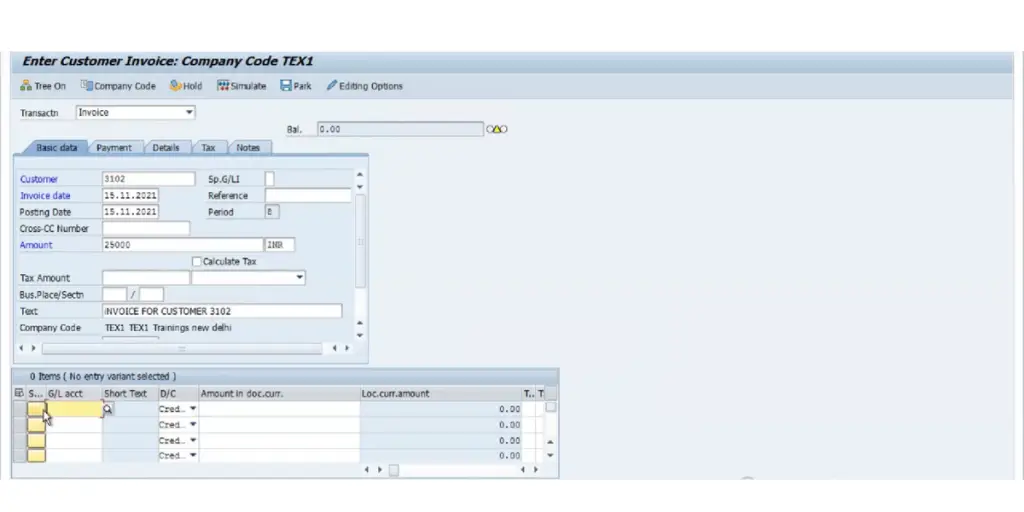

9. Recording the invoice

After receiving the receipt from the company, the supplier sends them the invoice for payment. The invoice will have all payment details related to the goods delivered.

T-code for invoice entry – FB70

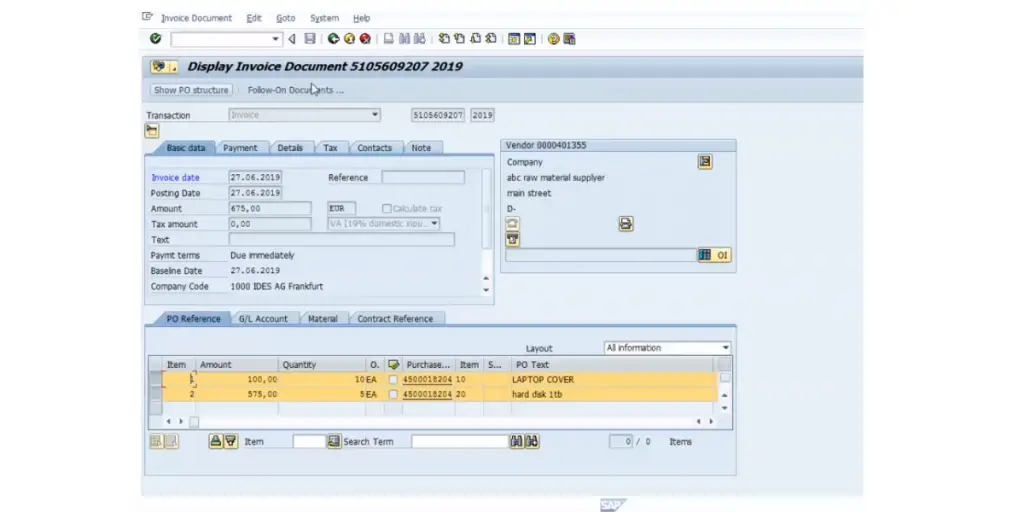

10. Three-way match

Once the company receives the invoice, the 3-way check will happen automatically by the standard system. Here invoices will be verified with goods receipt and purchase order for quantity and price.

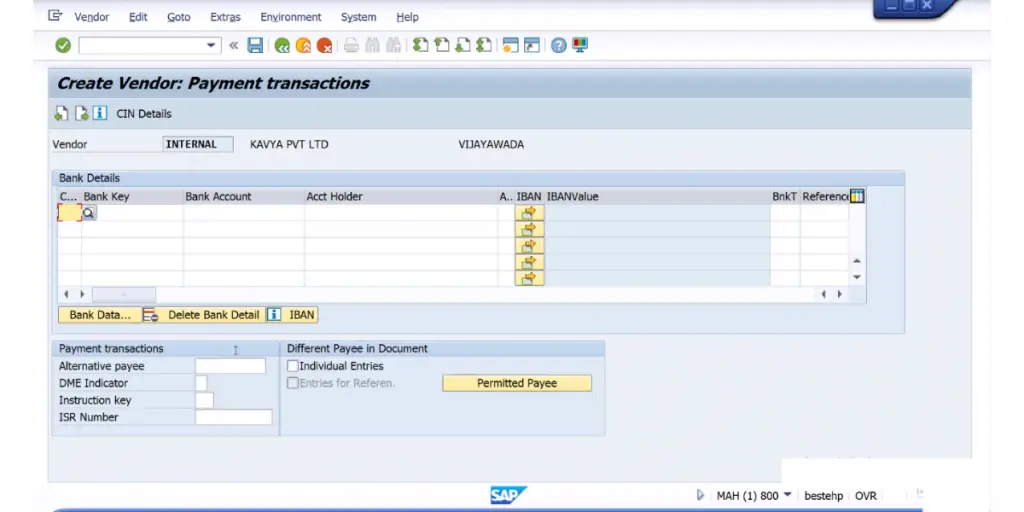

11. Making a payment to the supplier

Suppose the accounting department finds a match between the price, quantity, and terms and conditions within documents, it will pay the vendor (vendor payment) as per the agreed terms depending on the invoice due date.

12. Reporting

Once the vendor receives the payment, the complete process is documented, and accounting reports are created in FI.

What is the P2P procedure?

The procure-to-pay cycle (P2P Cycle) is the business process activity while creating and accepting purchase order payments for items or services.

First, the company asks for quotes from suppliers and then creates purchase orders. Once the supplier sends the goods, the company checks the quality. If it is good, the company issues an invoice to the supplier. After that, the company pays for the goods.

Modern ERP systems, including SAP, maintain good P2P process automation functionalities.

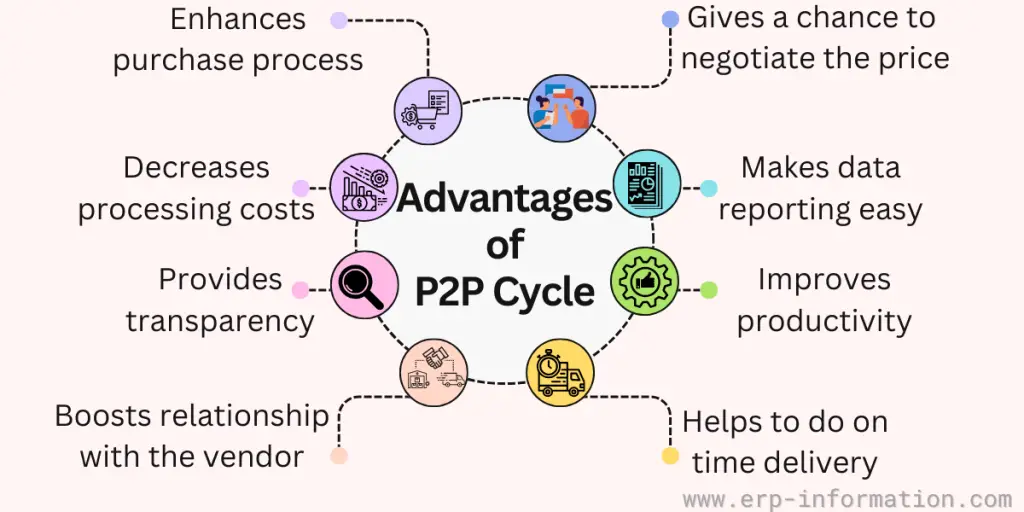

Advantages of procure-to-pay cycle

The purchase-to-pay cycle helps your business grow with the following advantages.

Enhances purchase process

The procure-to-pay cycle clearly defines the steps involved in the purchasing procedure. Hence it boosts the overall efficiency of the purchasing process.

Decreases processing costs

ERP purchasing module helps decrease the purchasing procedure’s processing cost by providing inventory tracking without paperwork.

Its online ordering ability helps users tune the stock levels as soon as they are acquired.

Provides transparency

The purchase-to-pay cycle helps the purchasing people and the vendors to see where the requisition is. In this way, it brings and boosts visibility into the supply chain.

Boosts relationship with the vendor

The purchase-to-pay process ensures that the orders are made precisely, and payments for the vendors are correctly created.

It also allows vendors and buyers to communicate and collaborate easily to solve disputes quickly. These essential things lead to improving the relationship with the vendor.

Gives a chance to negotiate the price

Since it improves the relationship with the vendor, buyers can ask to negotiate the price and contract terms.

It makes data reporting easy

A cloud-based inventory management system can easily retrieve real-time reports such as profitability reports, cost reports, and waste reports.

This information allows the managers to have a complete hold over their cash flow and make proper purchasing decisions.

Improves productivity

It optimizes the purchase process, which helps to improve productivity.

Helps to do on-time delivery

When productivity improves, you will deliver the product or services on time.

How do you improve the procure-to-pay cycle?

By following the below practices, you can improve your purchase-to-pay process.

- Retain the transparency of the process

- Implement the best software for purchase to pay

- Boost the supplier engagement

- Have well-organized contract management

- Enhance inventories

Automating P2P Cycle

The purchase-to-pay cycle involves many departments of the organization and many vendors.

Since it is a long process involving a lot of paperwork and administrative tasks, it demands a lot of money and time.

By automating the P2P cycle, organizations can optimize the entire process with the help of technology.

Decreased paperwork and human interference by automating the P2P process helps companies reduce operational costs.

Parameters to select the software for the procure-to-pay cycle

You need to choose the best technology for the P2P process. While selecting the software, consider the following parameters.

- Speed of the software: Select the application that operates fast so that it helps to reduce the time taken for the process and lessens the team’s strength.

- The flexibility of the software: Choose the application that can fulfill all your business needs and follow the business rules. The software should be upgradable to the new version and easily customizable according to your needs.

- Transparency: The application should give good insights to do your work. It should give you the correct information to reduce follow-ups inside and outside the company.

- Even sharing tasks: Make sure your software shares the task equally amongst your team members. For example, the software should automatically send requisitions to the vendor depending on past purchase history.

- Vendor communication: The application should help you communicate with your vendors, and it should also allow the vendors to check the invoices, quote approvals, and payments by themselves.

List of procure-to-pay software vendors

Many vendors are providing the software in the market. Here is the list of a few best vendors.

- SAP Ariba

- It provides simple, speedy, and user-friendly technology.

- It integrates effectively with other ERP systems.

- It offers flexible processes with budget checking and approval management.

- It provides the final receipt and reunion process.

- GEP Smart

- It is built with expertise in the procurement process.

- It provides comprehensive technology for the direct and indirect procurement processes.

- It provides a cloud platform with a unified upstream sourcing and downstream procurement process.

- Coupa BSM platform

- It provides complete visibility software and holds onto the procurement process.

- It provides a modern design experience.

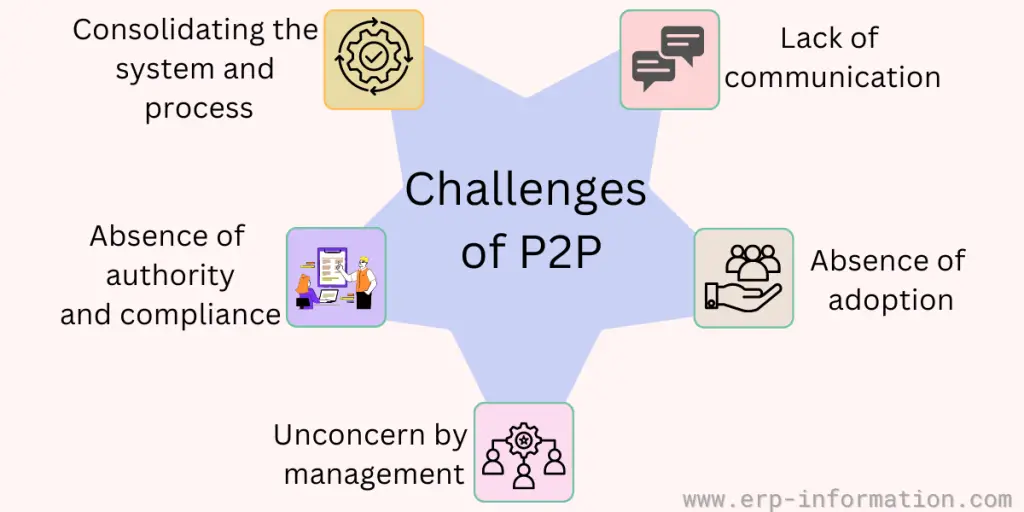

What are the challenges of a procure-to-pay cycle?

While processing purchase-to-pay, an organization faces many problems. Here is the list of challenges in the process.

Consolidating the system and process

You know that an organization has many departments, and each department will have its own systems and tools. That makes the integration of data difficult.

Absence of authority and compliance

Usually, governance and compliance affect the flexibility of the procuring process.

Unconcern by management

Generally, management thinks that the purchasing process is not a critical process. So, the management prioritizes enhancing the process with upgraded technologies.

Absence of adoption

Typically, A person who knows much more about purchasing and its complexities designs procurement tools or software.

Hence the software will be focused entirely on its features, not usability. So sometimes, users may find difficulty using the procurement system.

Users do not have enough training to use the system properly. Because of these issues, several businesses will not be interested in adopting Purchase-to-pay technology.

Lack of communication

The organization should consider the impact of its procurement software on employees’ morale and productivity.

It is crucial to ensure that changes in an enterprise don’t communicate with staff or clients, leading them to choose poorly across different technologies and affecting future output quality and delivery deadlines.

How to deal with the challenges?

A few suggestions deal with the above challenges the purchase-to-pay cycle process faces.

Automate the process

It is the best idea to automate the whole purchase-to-pay process. It helps to increase efficiency and decrease the process cost.

Conversion of purchase requisition into purchase order will be done automatically.

The approval process, invoicing, and other processes occur without complications or interruptions. Therefore, it is suitable for both vendors and the organization.

This automated system allows the purchasing team to concentrate on more valuable work. It also enables the accounts payable department to increase productivity and decrease expenses.

The technology pays the vendor on time. Hence there is no risk of late payment. It helps to bond the customer and supplier with a good bond.

Because of the early payment, you may also get some discounts, which helps reduce the cost.

Consider the user experiences

Automating the process becomes successful and worthy only when it serves its purpose. Therefore, it should be helpful and easy to use for the employees.

If the employees find it difficult while using the system or technology, there is no use in implementing the automated process.

Hence while implementing a new system, consider the employees’ or users’ experience.

Think of the proper design

Adopt a worker-centric method to design the procurement process. It helps to develop a system that considers user and usability. It will be easy to use for the worker as time goes on.

Adopt cloud system

You know that master data security is much more critical for an organization. Cloud technology helps the organization standardize the business process.

It enhances efficiency and reduces process expenses. It also allows the organization to change the system rapidly and efficiently.

Keep the process flexible

In the old purchase process, the process was done only in-house with one or two devices.

Nowadays, employees have started asking for access anywhere, regardless of devices.

So it allows the employee to work anywhere and anytime, enhancing the procure-to-pay process at full speed.

FAQs

What is a p2p cycle?

A P2P cycle is a business process where a company procures goods and services from vendors to produce the goods or deliver the service it provides to its customers.

Implementing a P2P system is to reduce expenses associated with inefficient manual processes. This equates to faster order fulfillment, increased efficiency, lower staff turnover rates, decreased accounting errors, and more timely information entry into financial systems.

Ultimately, this leads to better compliance with corporate policies and regulatory requirements and saves companies money that they have been overpaying for inferior paper-based procurement methods.

What is procure-to-pay software?

Procure-to-pay software is a technology that automates the complete procure-to-pay cycle and allows the user to control each process step. In addition, it will enable the flow of information from the purchasing department to the account payable department efficiently.

This software organizes all aspects of an organization’s purchase orders in one place, including supplier information, asset tracking, invoicing, and payment processing. In addition, it provides predictive analytics about future expenses and inventory needs.

It also generates reports on transaction history which can be used for planning business expansion or improvements. Procurement professionals often input funds into this program before making payments to assign as soon as due.

This allows for savings on interest rates and risk mitigation through structured funding periods.

Conclusion

This blog post has given you a basic understanding of the 12 steps involved in the SAP Procure-To-Pay cycle.

The Procure-to-Pay cycle is a process for moving goods from purchase to delivery. It takes multiple stages and can be made more efficient through automation.

Future technology could be the blockchain in procure-to-pay to enhance transparency.

The blockchain is an open, distributed ledger that can record activities between two parties, verifiable and unchanging.

Not just SAP MM, Oracle apps, PeopleSoft, and similar enterprise software solutions provide these functionalities.

[You are free to copy and distribute materials in this article.]